Non-woven bag tidying machine

A technology of non-woven bags and bag unscrambling machines, which is applied in the field of bag unscrambling machines, can solve the problems of easy safety accidents, low efficiency, and high labor costs, and achieve the effects of improving production efficiency, solving low efficiency, and automatically and efficiently sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

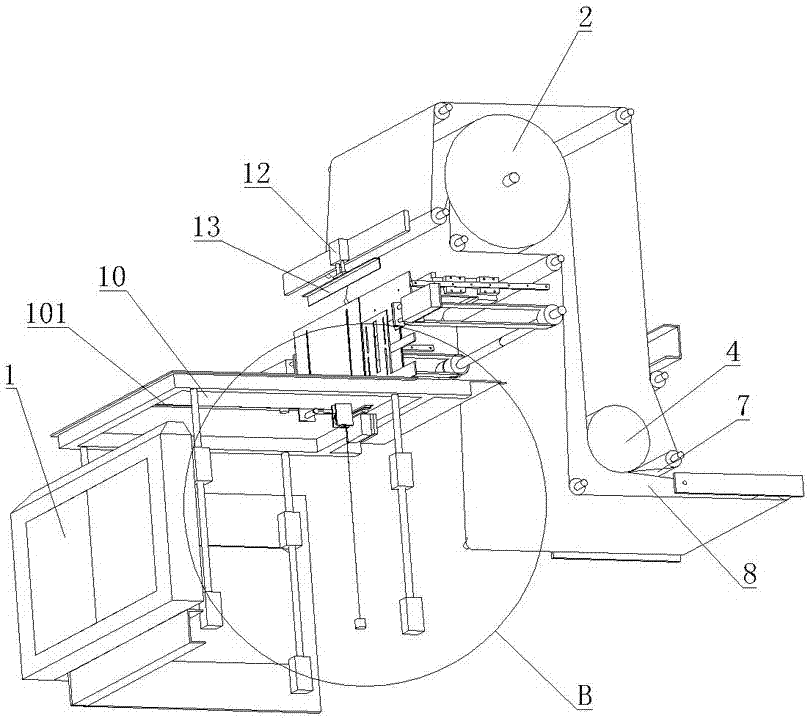

[0016] The present invention will be further described below in conjunction with accompanying drawing:

[0017] As shown in the figure, the non-woven bag unscrambling machine has a frame 1, and the frame 1 is provided with a driving roller 2 and a pressure roller 3, and the driving roller 2, the pressure roller 3 and the first group of guide The roller 4 is equipped with a first conveyor belt 7, and the driving roller 2, the pressure roller 3 and the second set of guide rollers 5 are equipped with a second conveyor belt 8, and the first conveyor belt 7 and the second conveyor belt 8 are partly in close contact with each other. Combined to form a bag transfer section, when the non-woven bag passes through the bag transfer end, it will be flattened again to facilitate subsequent finishing, and will be pinched and sent to the output end with the operation of the driving roller 2 to stand upright and drop.

[0018] Below the driving roller 2 is provided with a push plate 11 that c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com