A zero-bias self-calibration mems gyroscope and its zero-bias self-calibration method

A self-calibration, gyroscope technology, used in gyroscope/steering sensing equipment, gyro effect for speed measurement, instruments, etc., can solve the problems of inconsistent zero bias, increased working time, and high repeatability requirements of temperature sensor gyroscopes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The MEMS gyroscope zero-bias self-calibration method based on driving / detection mode inversion of the present invention is described in detail in conjunction with the accompanying drawings and specific embodiments.

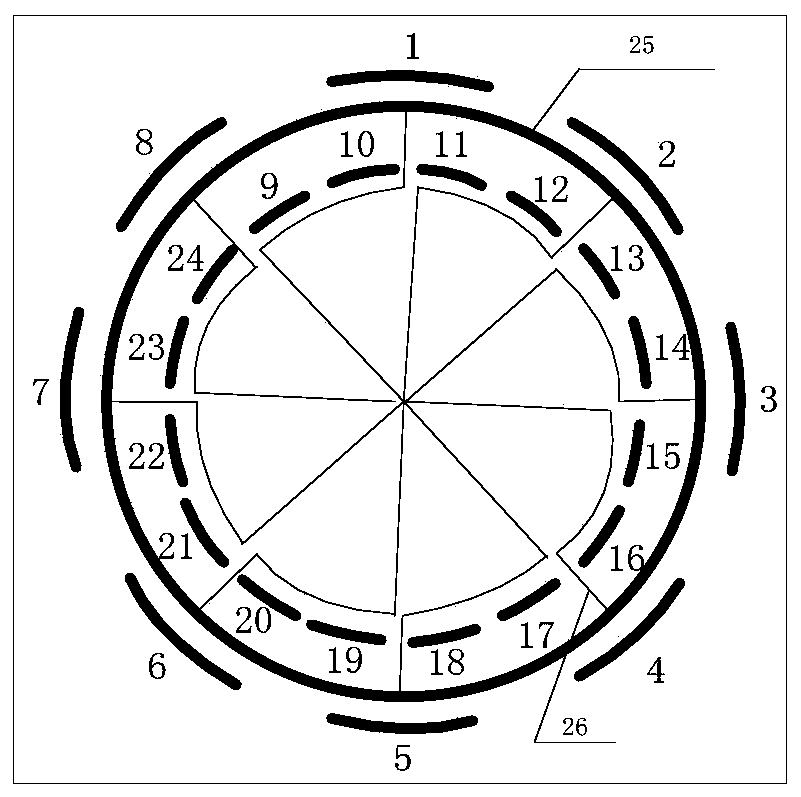

[0043] figure 1 It is the structural diagram of the resonance ring of the MEMS gyroscope in the present invention. The resonant ring 25 is fixed by octagonal support beams 26 arranged in the circumferential direction. Eight electrodes are evenly distributed on the outside of the resonant ring 25, and they are electrodes 1 to 8 clockwise, wherein electrodes 1 and 5 are the driving electrodes of the driving mode, electrodes 3 and 7 are the detection electrodes of the driving mode, and electrodes 2 and 7 are the detection electrodes of the driving mode. Electrode 6 is the driving electrode of the detection mode, and electrode 4 and electrode 8 are the detection electrodes of the detection mode. When the gyroscope works in reverse in the two modes, the functio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com