Wear simulation test bed for bottom pintle friction pair of miter gate

A technology for simulating test benches and miter gates, which is applied in the field of gate performance test equipment, and can solve the problems of increased wear of the bottom hinge of miter gates, long time consumption, and lax closing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The embodiments of the present invention will be further described below in conjunction with the drawings.

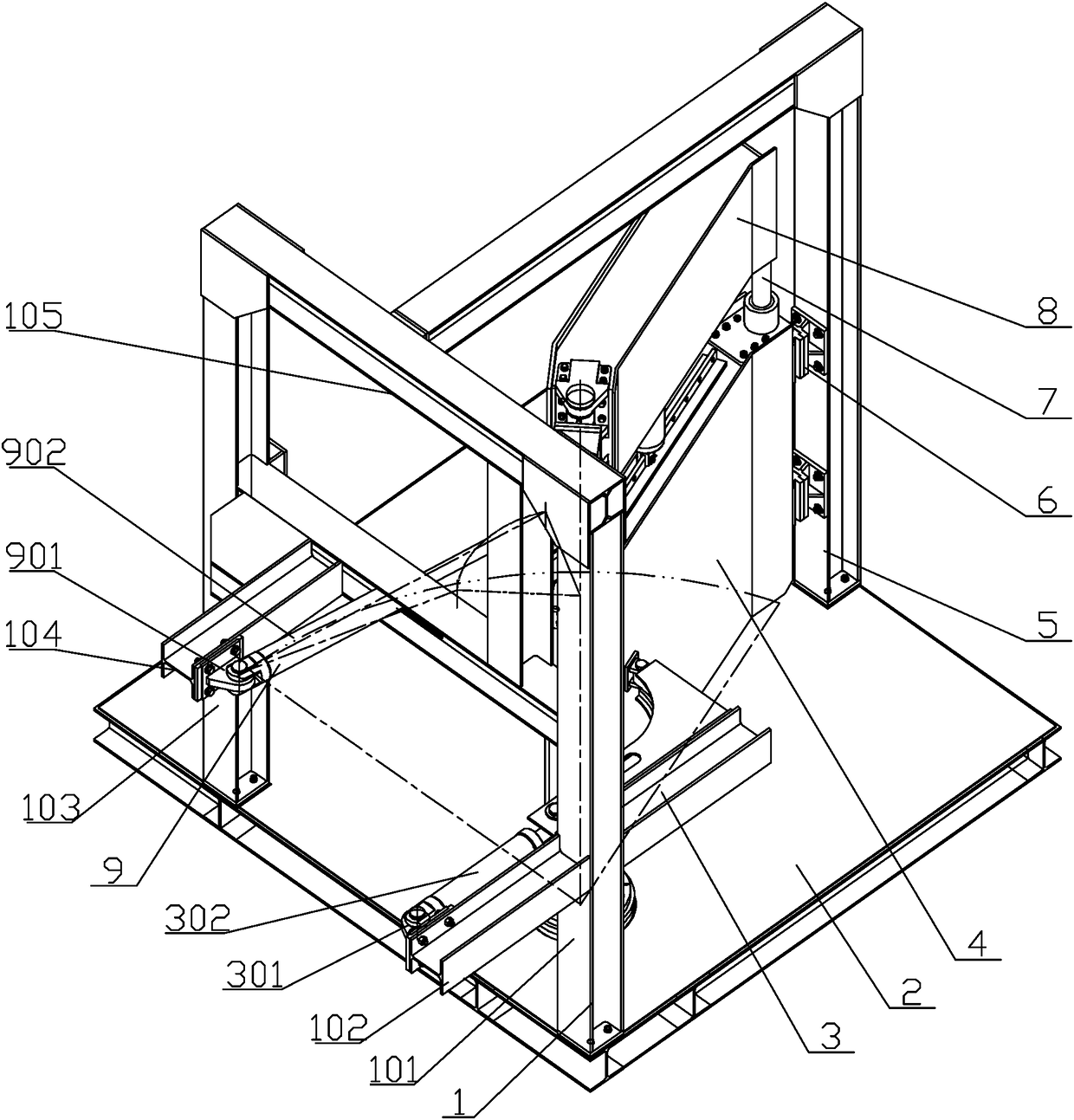

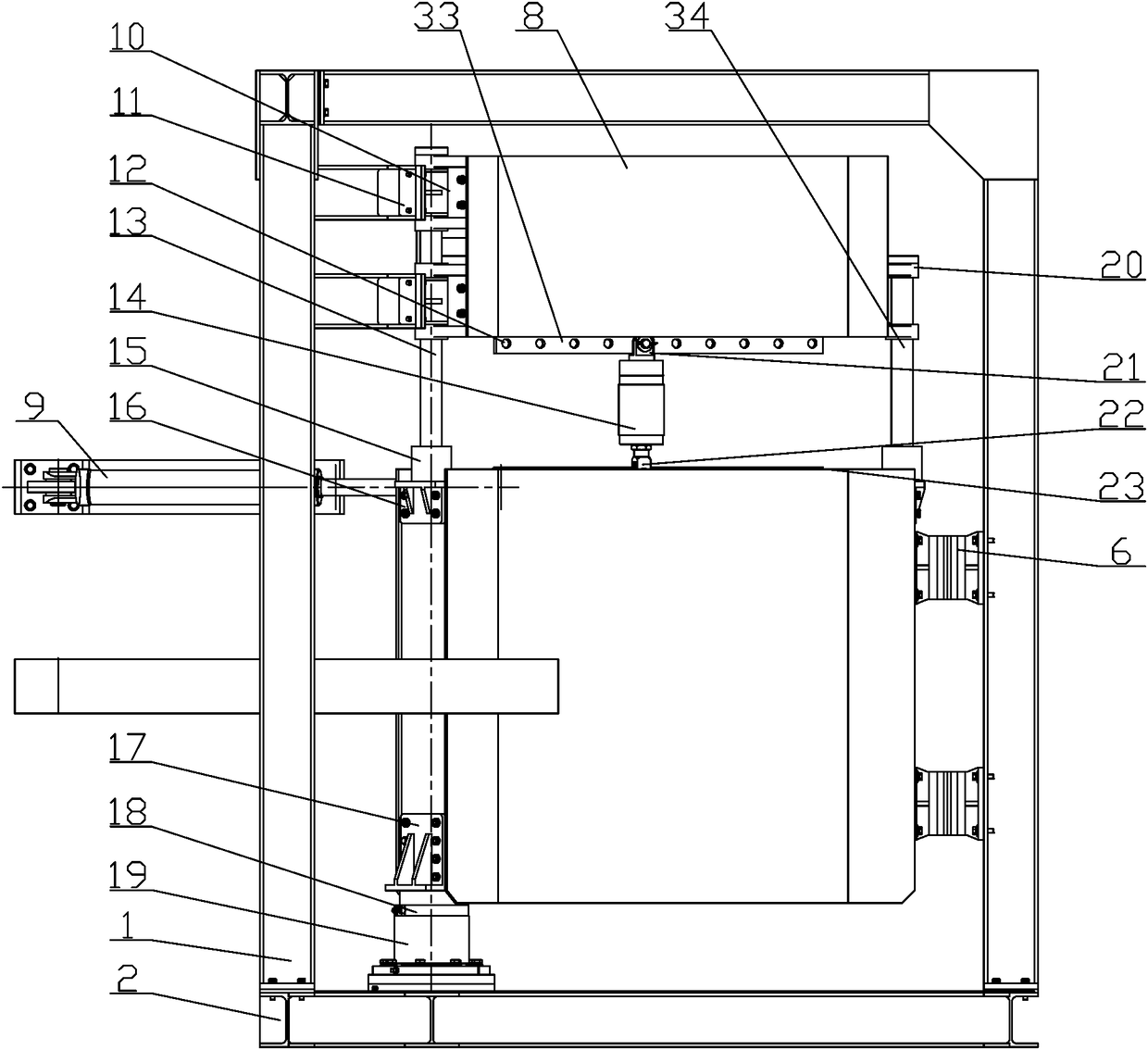

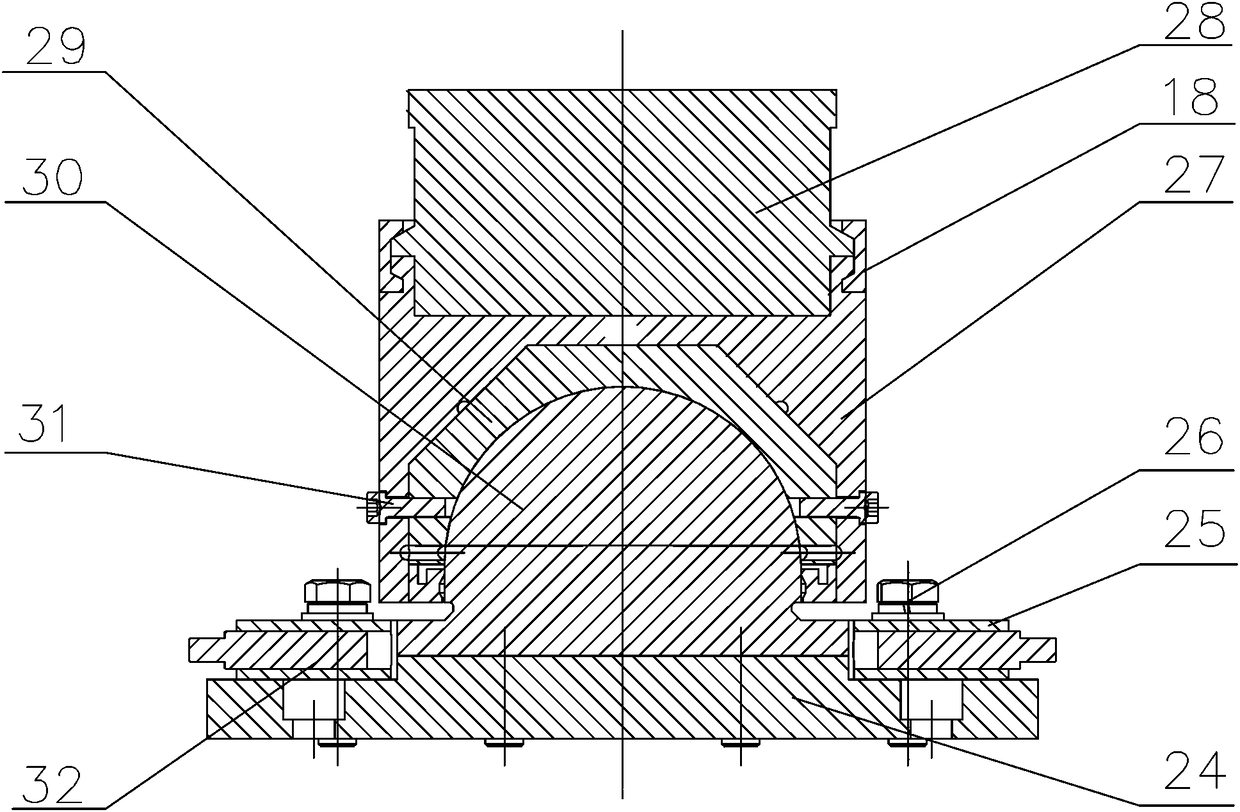

[0043] Such as Figure 1-3 Among them, the friction pair wear simulation test bench for the bottom pivot of the miter gate includes the stand 1, the lower end of the stand 1 is bolted to the base 2, the upper end is bolted to the mast 5, and the side is used to fix the hoist 9 and the damping device 3. .

[0044] Further, the lower end of the door frame 5 is bolted to the base 2, and a stopper 6 is installed on the side to simulate the actual interaction between two gates.

[0045] Furthermore, the stopper 6 is made of nylon 66 and is divided into a fixed stopper and a movable stopper. The fixed stopper is fixed on the door frame 5 and the movable stopper is installed on the gate body 4.

[0046] Further, the gate hoist 9 is a hydraulic cylinder, one end is hinged to the stand 1, the other end is hinged to the gate body 4 to provide power for the opening and closing of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com