Fine motion device and fine motion testing device

A micro-movement device, a technology for testing samples, applied in the direction of measuring device, using mechanical device, testing wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

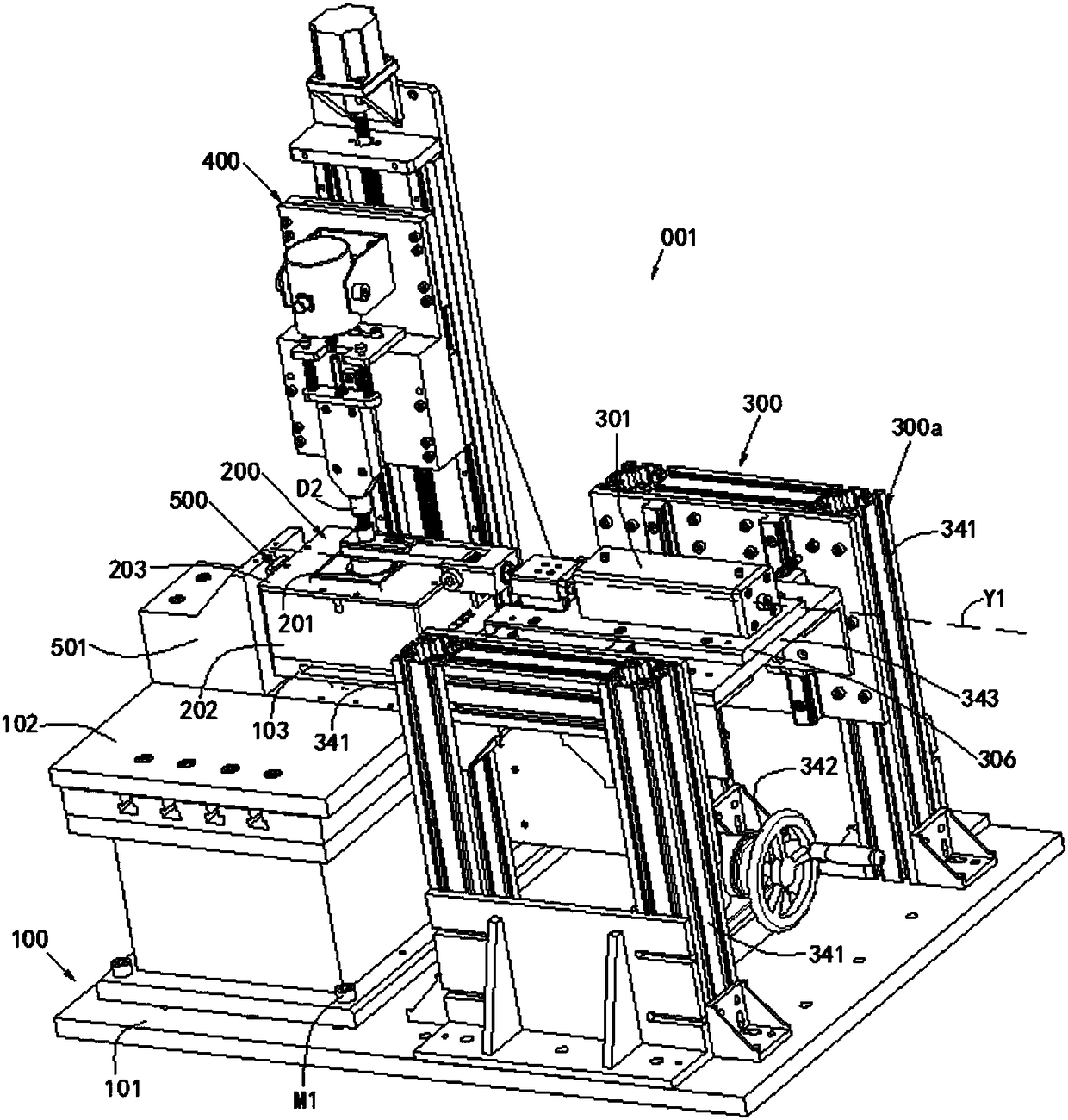

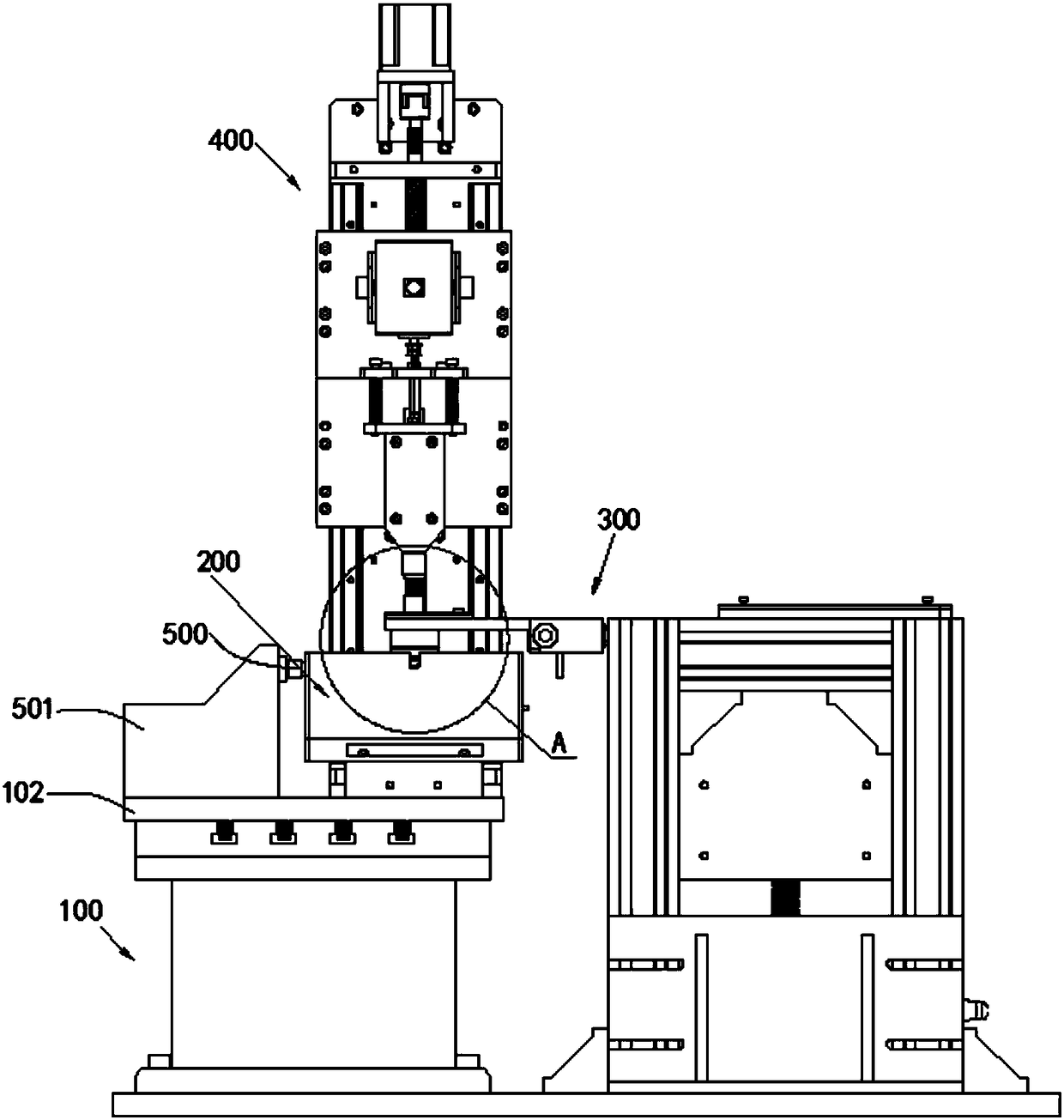

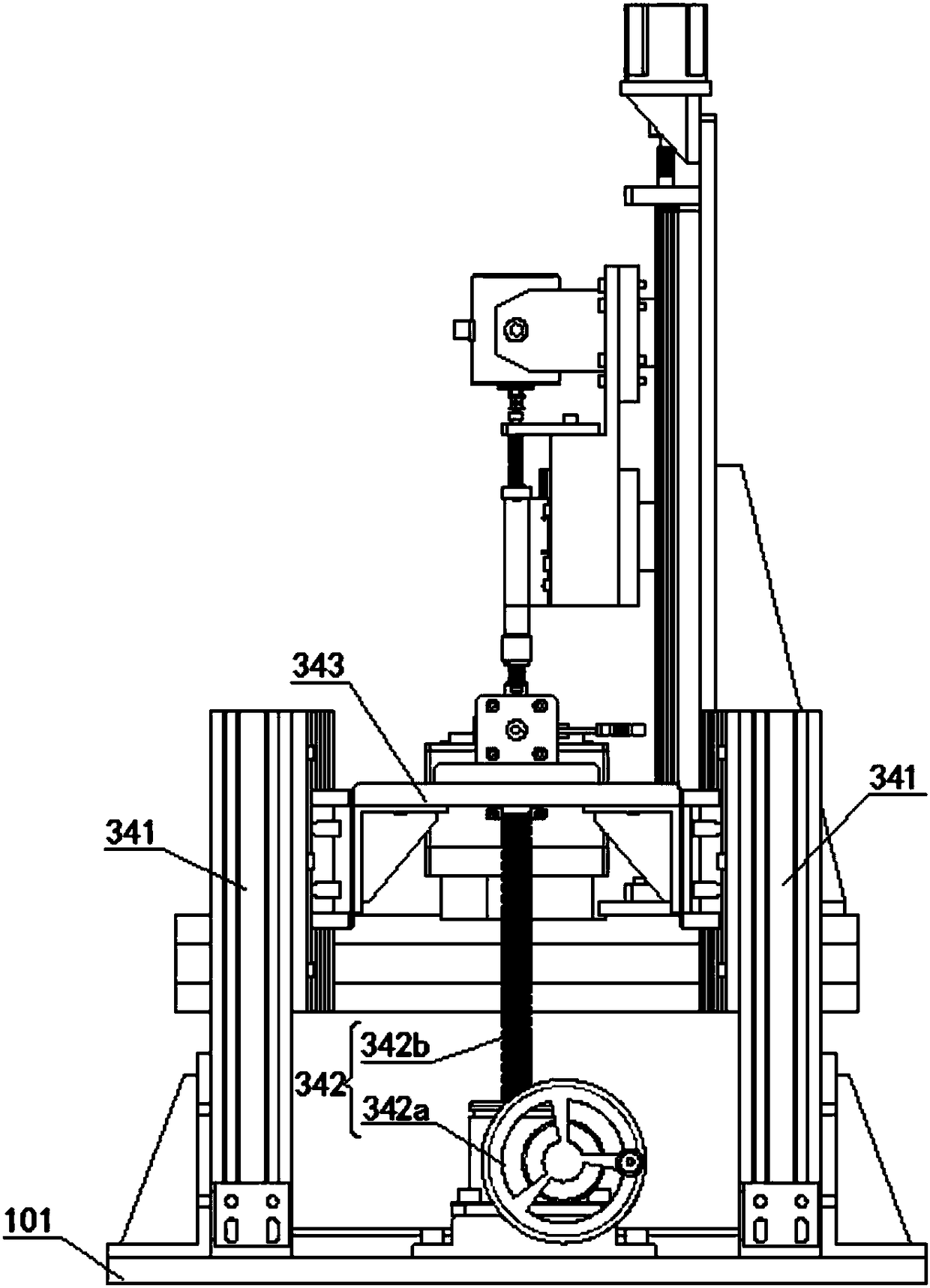

[0066] figure 1 shows a perspective view of an implementation of the fretting test device 001 of the embodiment of the present invention; figure 2 for figure 1 Frontal view of part of the structure; image 3 for figure 1 side view.

[0067] See figure 1 (for coordination see figure 2 , image 3 ), the fretting test device 001 in this embodiment includes: a frame 100 , a sample stage 200 , a fretting device 300 , a load applying device 400 and a friction measuring device 500 .

[0068] Cooperate see Figure 4 , wherein the sample stage 200 is slidably fitted to the frame 100 along the first linear direction Y1, and the sample stage 200 includes a sample holder 201 for holding the test sample S2. The form of the chuck of the sample holder 201 can be set in various forms, and can be determined according to the shape or other physical and chemical properties of the test sample S2 to be clamped. For example, for a circular test sample S2, the clamping head of the sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com