Coupling convenient to disassemble and assembling method

A technology of couplings and coupling sleeves, which is applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problems of troublesome disassembly of couplings and lower work efficiency, and achieve convenient and quick disassembly, simple and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

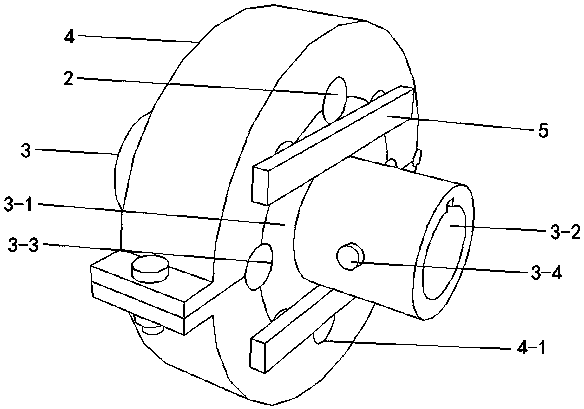

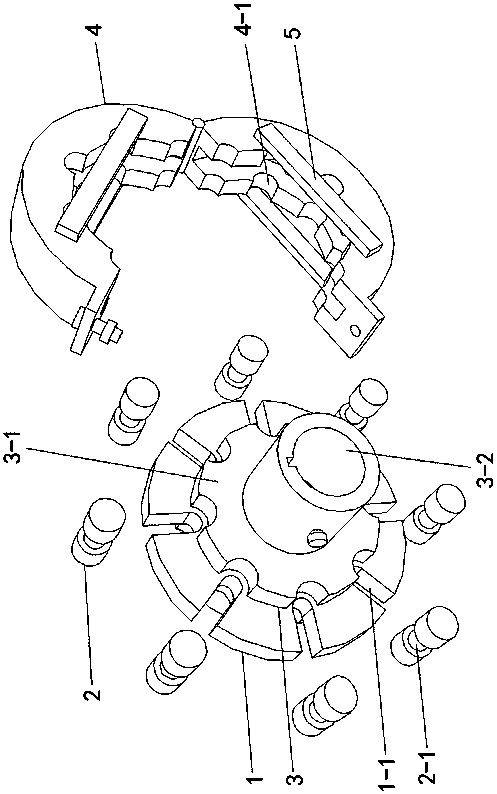

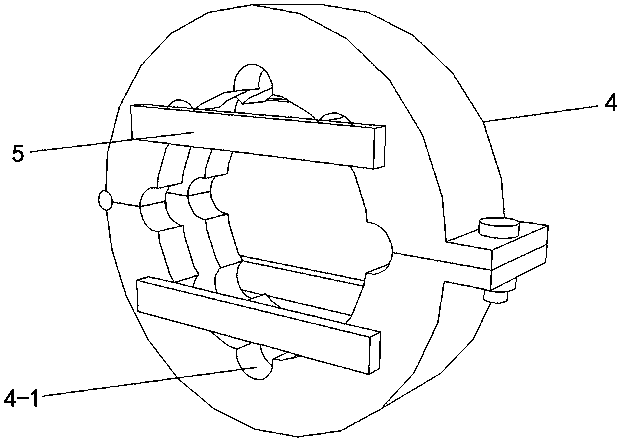

[0017] Specific implementation mode one: as Figure 1~Figure 4 As shown, the present invention discloses a coupling that is easy to disassemble, including two coupling sleeves 3, and the coupling that is easy to disassemble also includes a central positioning plate 1, a positioning hoop 4, and four limit rods 5 and a plurality of positioning cylinders 2, the central positioning plate 1 is a circular plate, the circumferential position of the central positioning plate 1 is provided with a plurality of gaps 1-1 at equal angles along its circumferential direction, and the multiple gaps 1-1 They are arranged radially along the central positioning plate 1, and the plurality of positioning cylinders 2 are set in one-to-one correspondence with the plurality of gaps 1-1, and the middle of the side walls of the plurality of positioning cylinders 2 are all concavely provided with annular locking grooves 2-1, and They are respectively inserted into the corresponding gaps 1-1 through the ...

specific Embodiment approach 2

[0018] Specific implementation mode two: as figure 1 , 4 As shown, this embodiment is a further description of specific embodiment 1. Each side wall of the shaft sleeve 3-2 is provided with a threaded through hole along its radial direction, and the threaded through hole is screwed with a Top wire 3-4. The effect is to fasten the shaft rod to prevent it from breaking away from the shaft sleeve 3-2.

specific Embodiment approach 3

[0019] Specific implementation mode three: as figure 2 As shown, this embodiment is a further description of Embodiment 1 or Embodiment 2, and the number of the plurality of positioning cylinders 2 is 3-8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com