Flat plate transport vehicle with vertical flip opening type box covers

A vertical flipping and opening technology, applied in the directions of transportation and packaging, vehicle parts, and the superstructure of trucks, etc., can solve the problems of falling goods, not easy to bind and fasten, large manpower, etc., so as to reduce the weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

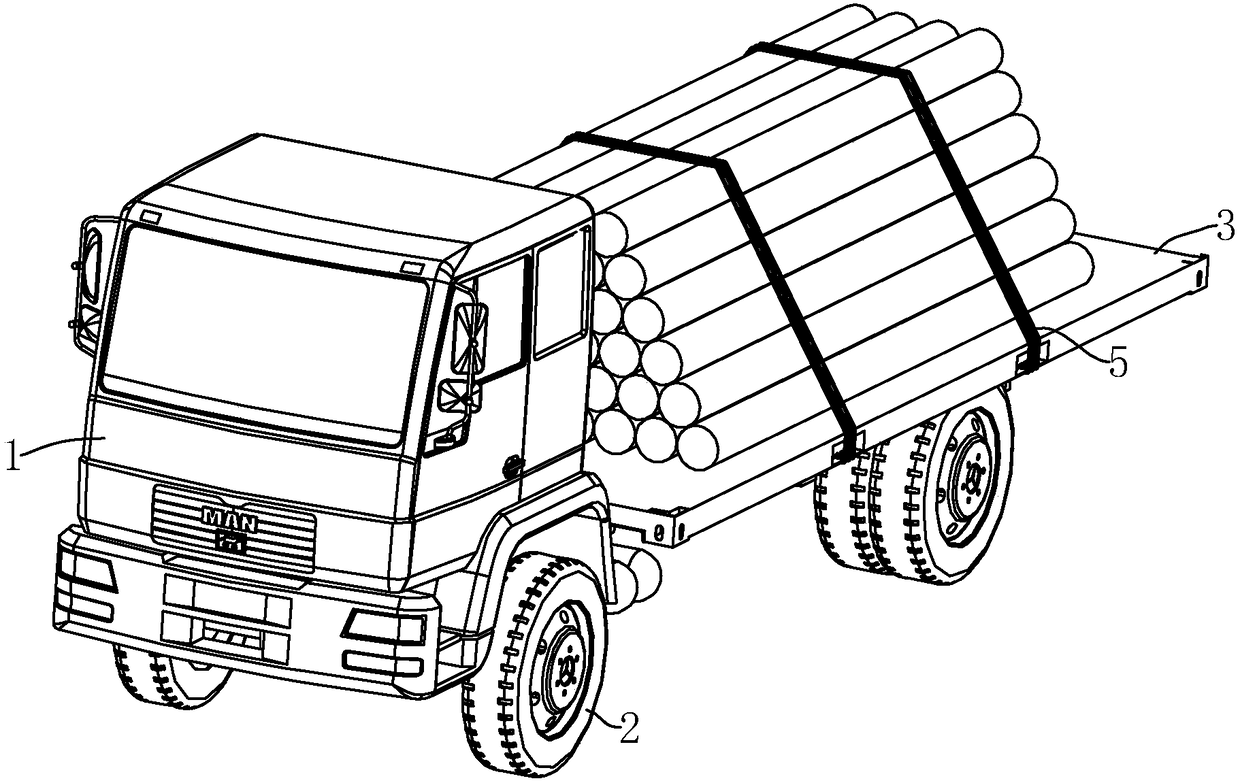

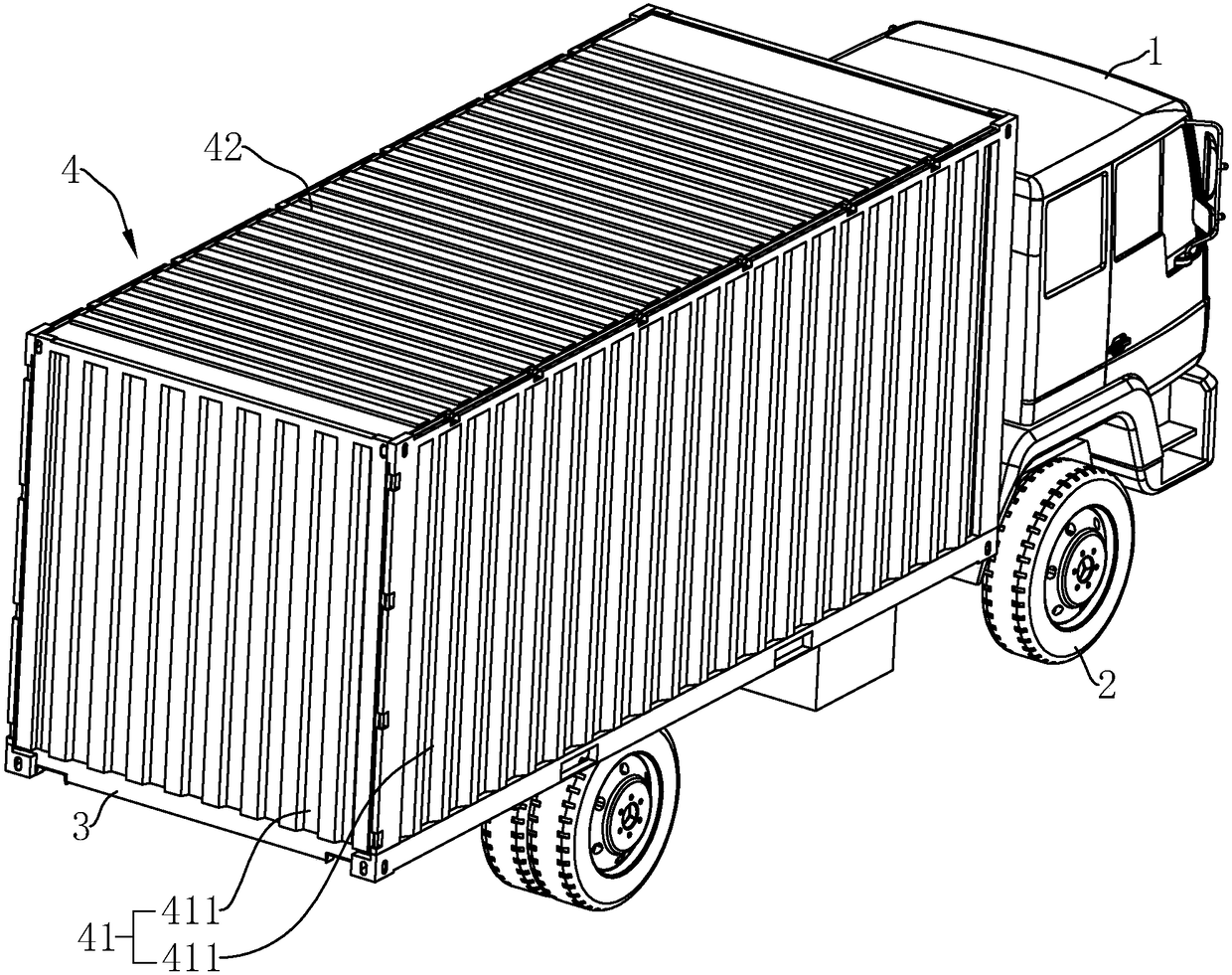

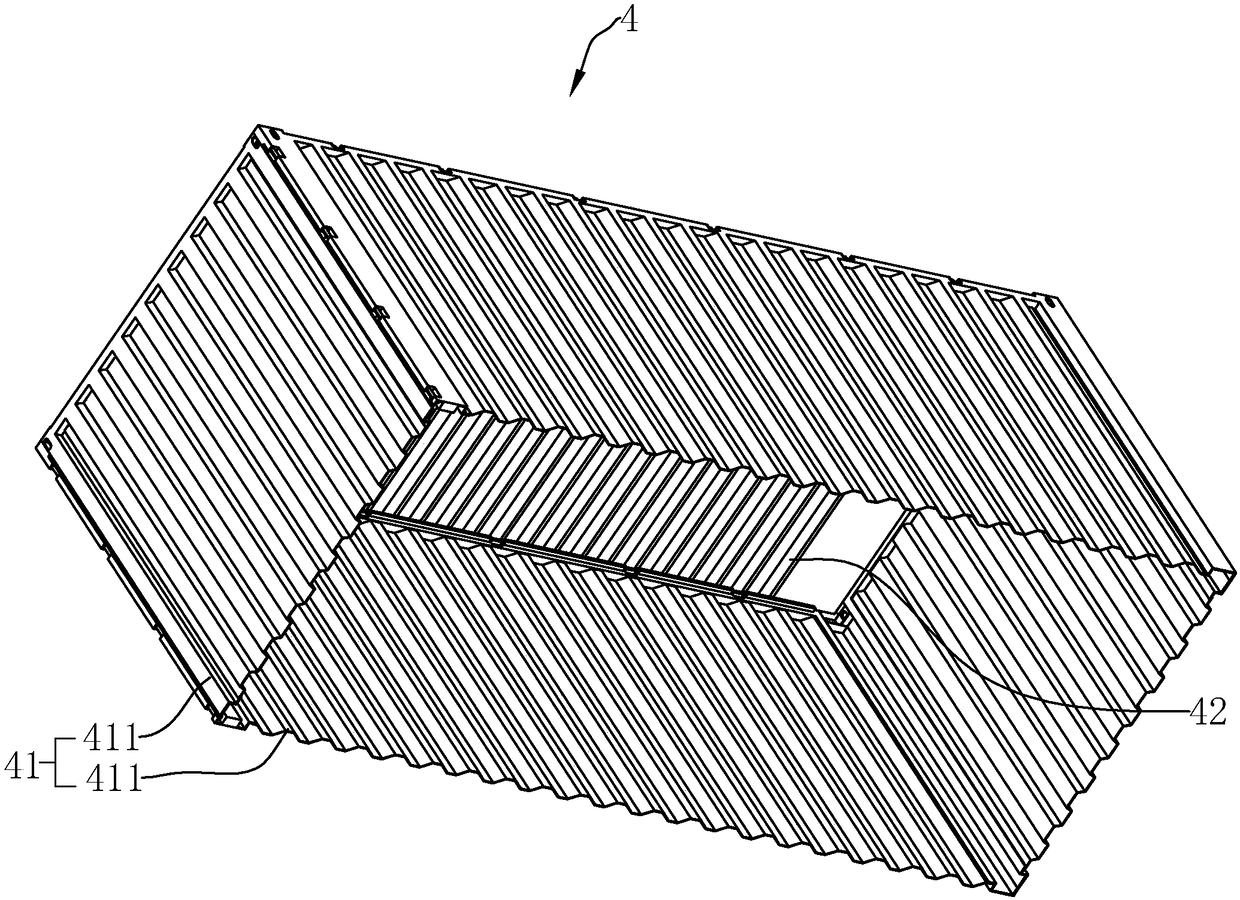

[0046] A flatbed transport vehicle with a vertically flip-openable lid, such as figure 2 As shown, it includes the front 1, the wheels 2 and the supporting plate 3, the supporting plate 3 is connected with the wheel 2 in rotation, the supporting plate 3 is connected with the front 1, the goods are fixedly placed on the supporting plate 3, and the front 1 can provide power to drive through the wheels 2 The pallet 3 moves along the ground to realize the function of transporting goods. combine image 3 The flatbed transport vehicle also includes a container 4 fixedly connected to the pallet 3, the container 4 includes a casing 41 and a cover 42, and the casing 41 includes four side panels 411 vertically fixedly connected to the pallet 3, The case cover 42 is connected to the top of the casing 41. After opening the case cover 42, the goods can be put into the interior of the container 4. The side plates 411 can limit the movement of the goods in the horizontal direction and drop...

Embodiment 2

[0056] The difference from Example 1 is that, as Figure 10 As shown, the box cover 42 has more than two, preferably three, and the three box covers 42 are arranged side by side and are connected to the box body 41 on the same side, so that the weight of a single box cover 42 can be reduced, and the box cover 42 can be turned over and opened. Save effort in the process.

Embodiment 3

[0058] The difference from Example 1 is that, as Figure 11 As shown, the box cover 42 includes a fixed cover 421 and a sliding cover group 422, the fixed cover 421 is horizontally fixedly connected to one end of the top of the casing 41, the sliding cover group 422 includes a primary sliding cover 4221 and a secondary sliding cover 4222, the primary sliding cover 4222 Both the cover 4221 and the secondary sliding cover 4222 are horizontally slidably connected with the top of the casing 41, the primary sliding cover 4221, the secondary sliding cover 4222 and the fixed cover 421 are staggered vertically, and the secondary sliding cover 4222 can slide into To the bottom of the first-level sliding cover 4221, the first-level sliding cover 4221 can slide into the bottom of the fixed cover 421 to open the top opening of the box body 41; When the other end and the sliding cover slide to be located between the secondary sliding cover 4222 and the fixed cover 421 , the fixed cover 421...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com