Suspension rod force and main cable shape combined calculation method for suspension bridge

A calculation method and technology of suspension bridges, applied in calculation, special data processing applications, instruments, etc., can solve the problems of main cable and saddle change, saddle simulation difficulty, inconvenient calculation of boom force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

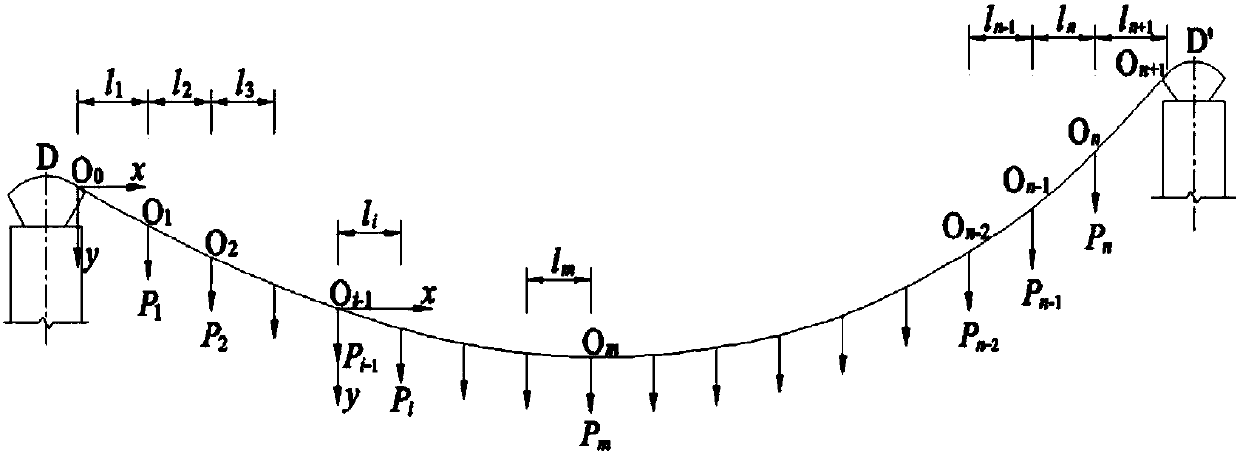

[0072] The method of the present invention uses an analytical method to calculate the shape of the main cable, and uses the finite element method to calculate the force of the boom.

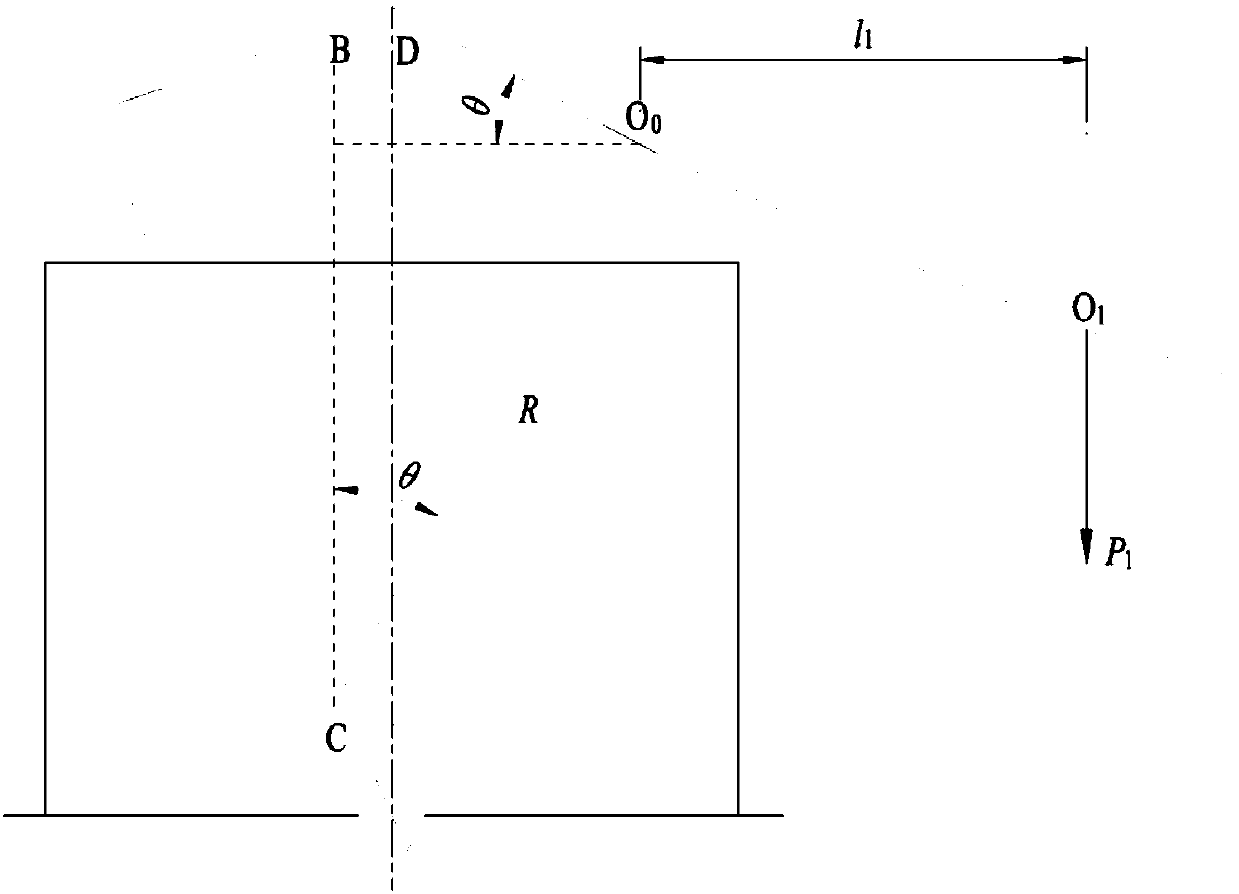

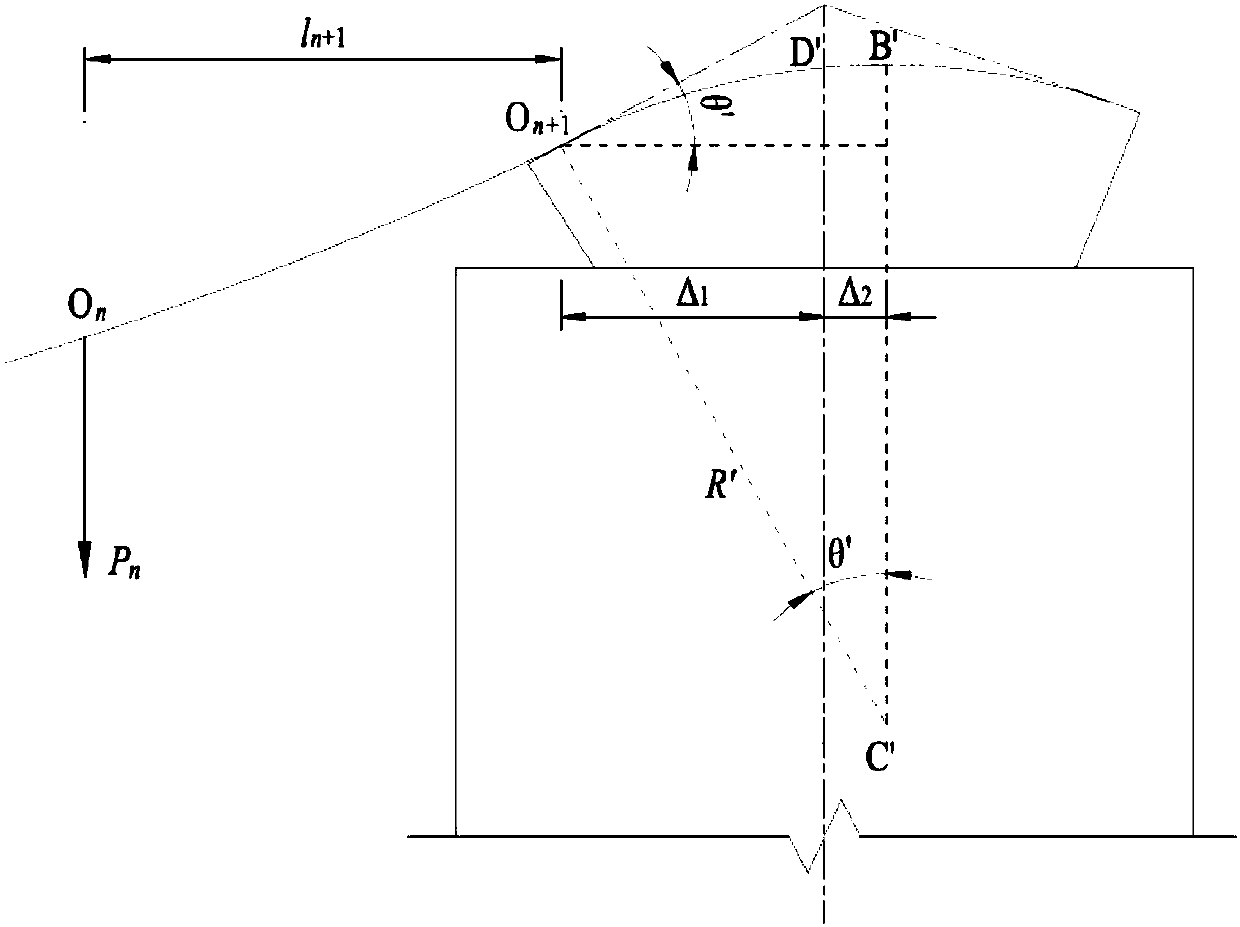

[0073] Due to the force of the boom, the main cable in the bridge state is a multi-segment catenary with knuckles, that is, the line between adjacent suspension points is a catenary. To calculate the main cable shape of the bridge, the mid-span is generally calculated first. Such as figure 1 As shown, the coordinate system is established with the left tangent point and each hanging point as the coordinate origin, the x-axis is horizontal to the right, and the y-axis is vertically downward, then the catenary line equation of any section of the main cable can be expressed as:

[0074]

[0075] In the formula, c=-H / q, H is the horizontal force of the main cable in the bridge state (kN), q is the self-weight load concentration of the main cable in the bridge state (kN / m), a i and b i is the par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com