A testing device and method for testing the liquefaction temperature of insulating gas

A technology of insulating gas and liquefaction temperature, which is used in measuring devices, testing dielectric strength, measuring fluid pressure, etc., can solve the problem of inability to verify the liquefaction temperature in field testing, and achieve the effect of enhancing accuracy and reliability and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

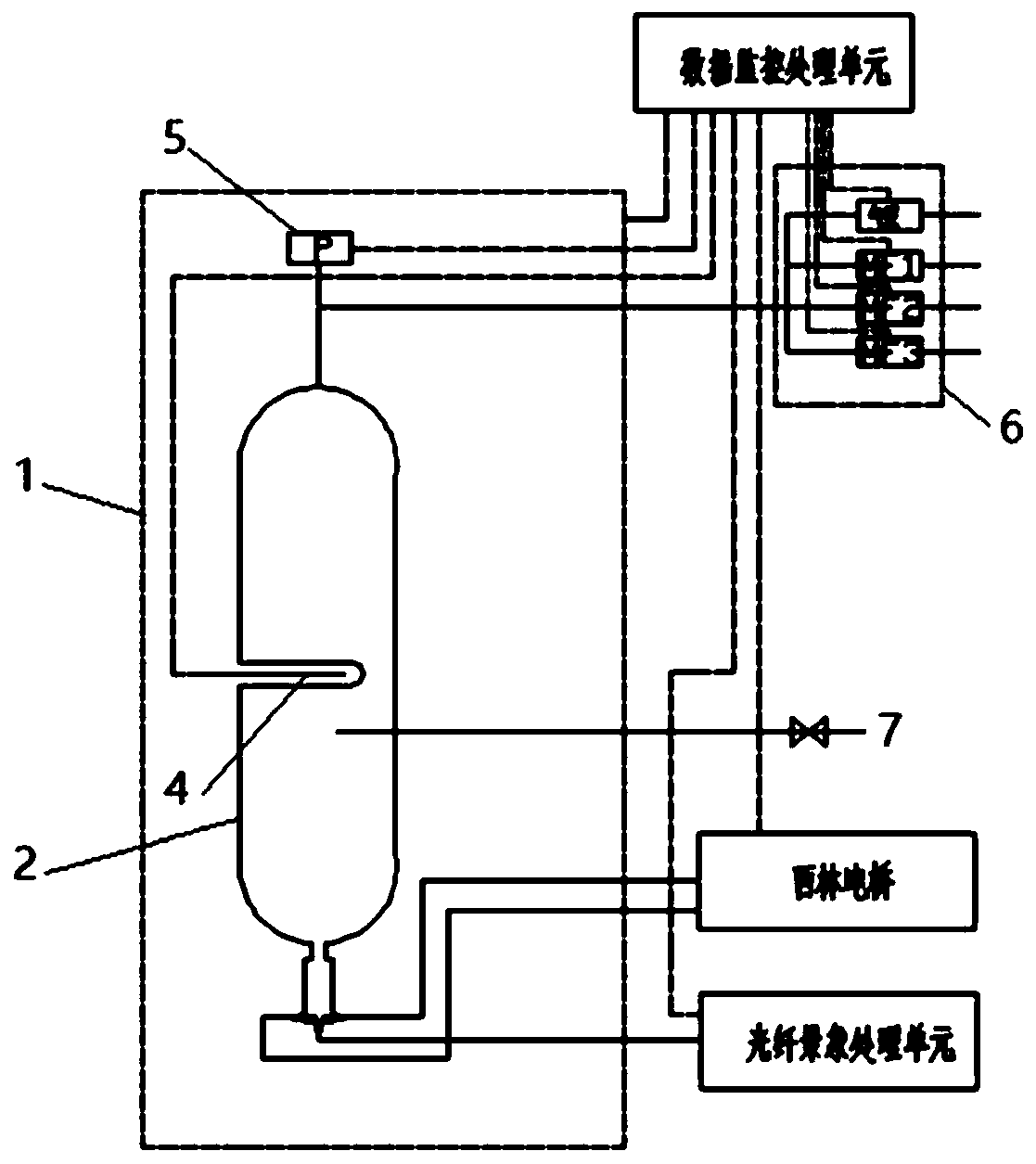

Embodiment 1

[0070] refer to Figure 4 , use manual operation or program setting to set the temperature of the incubator through the data monitoring and processing unit as the initial temperature is 293K, the end temperature is 253K, and it is constant for 5 minutes per 1K, the gas injection pressure of the constant volume bottle is set to 2900kpa, and the gas injection port is Gas distribution unit MF1 port, select the measurement mode to draw the pressure and temperature curve.

[0071] Before gas injection, start the gas pump, empty the residual gas in the constant volume bottle until the vacuum degree reaches the set value, inject a gas of 2900kpa, start the thermostat, keep constant for 5 minutes every 1K, record the pressure gauge value, record the temperature value, and draw two-dimensional At the first point of the plane curve, lower 1K and keep it constant for 5 minutes, record the pressure gauge value, record the temperature value, draw the second point of the two-dimensional pla...

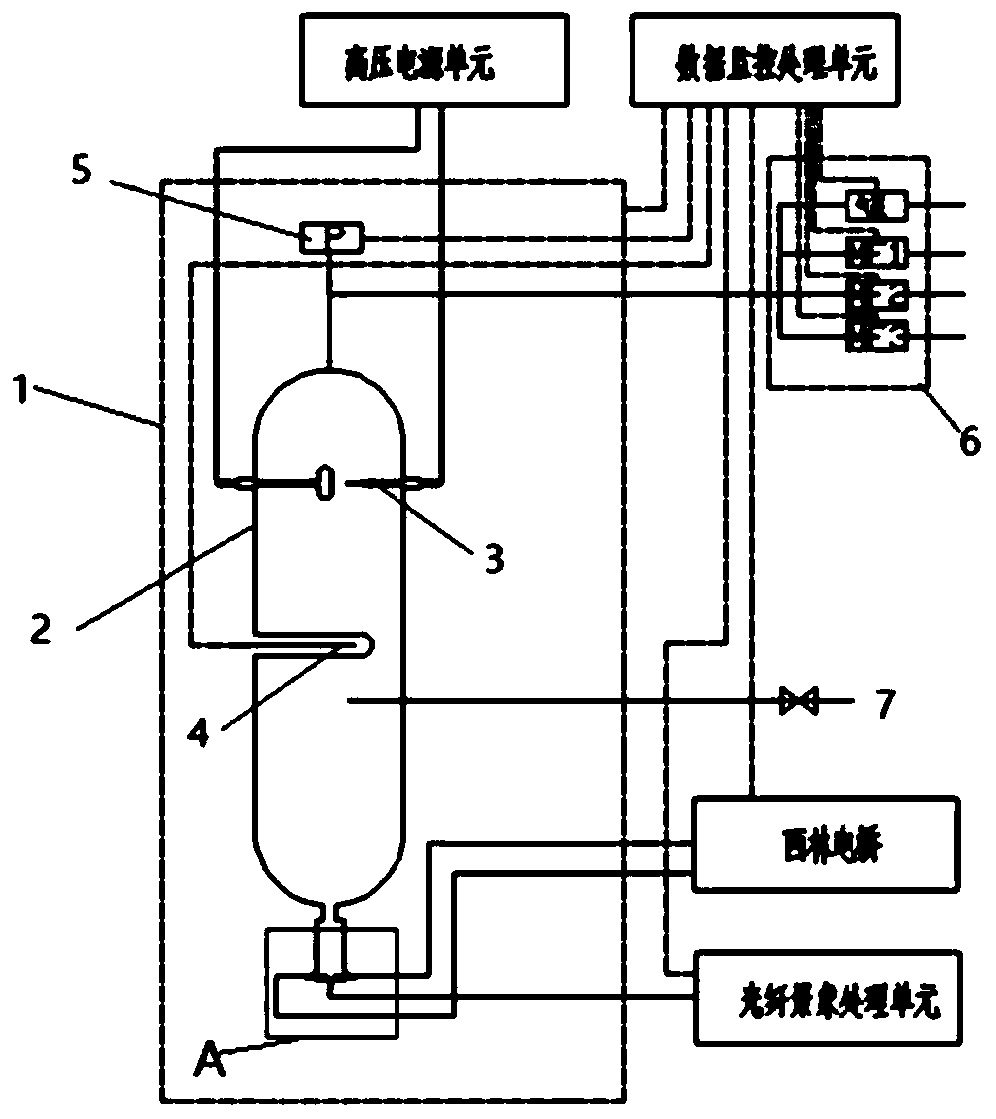

Embodiment 2

[0073] refer to Figure 5 , use manual operation or program setting to set the temperature of the incubator through the data monitoring and processing unit as the initial temperature is 293K, the end temperature is 443K, 293K to 383K, every 20K constant for 5min, 383K to 423K, every 1K constant for 5min, 423K To 443K, keep constant for 5 minutes every 20K, set the gas injection pressure of the constant volume bottle to 100kpa, the gas injection port is MF1 port of 3 gas distribution units, select the measurement mode to draw the pressure temperature curve.

[0074] Before gas injection, start the gas pump, empty the residual gas in the constant volume bottle until the vacuum degree reaches the set value, inject a certain gas of 100kpa, start the thermostat, record the pressure gauge value and temperature value according to the program, and draw a two-dimensional plane curve The first point: increase the temperature and record the pressure gauge value according to the program, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com