Drawer assembly and refrigerator

A drawer and component technology, applied in the field of drawer components and refrigerators, can solve the problems of inconvenient installation and removal of guide rails, affecting production efficiency and user experience, and high impact force between drawers and guide rails, achieving high installation and operation efficiency and low cost , The effect of saving mold costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

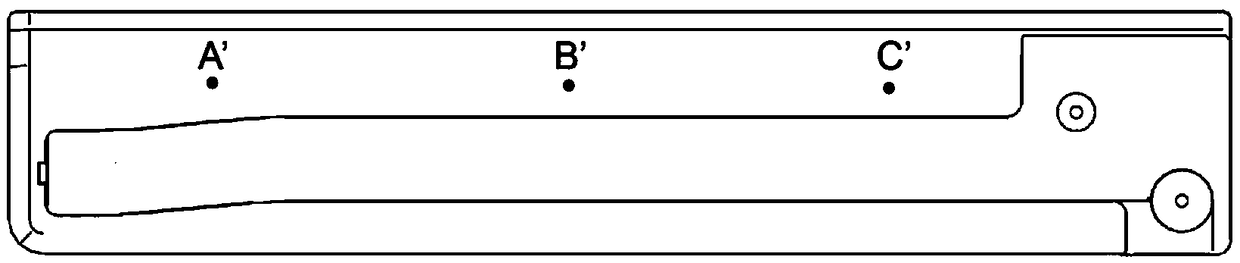

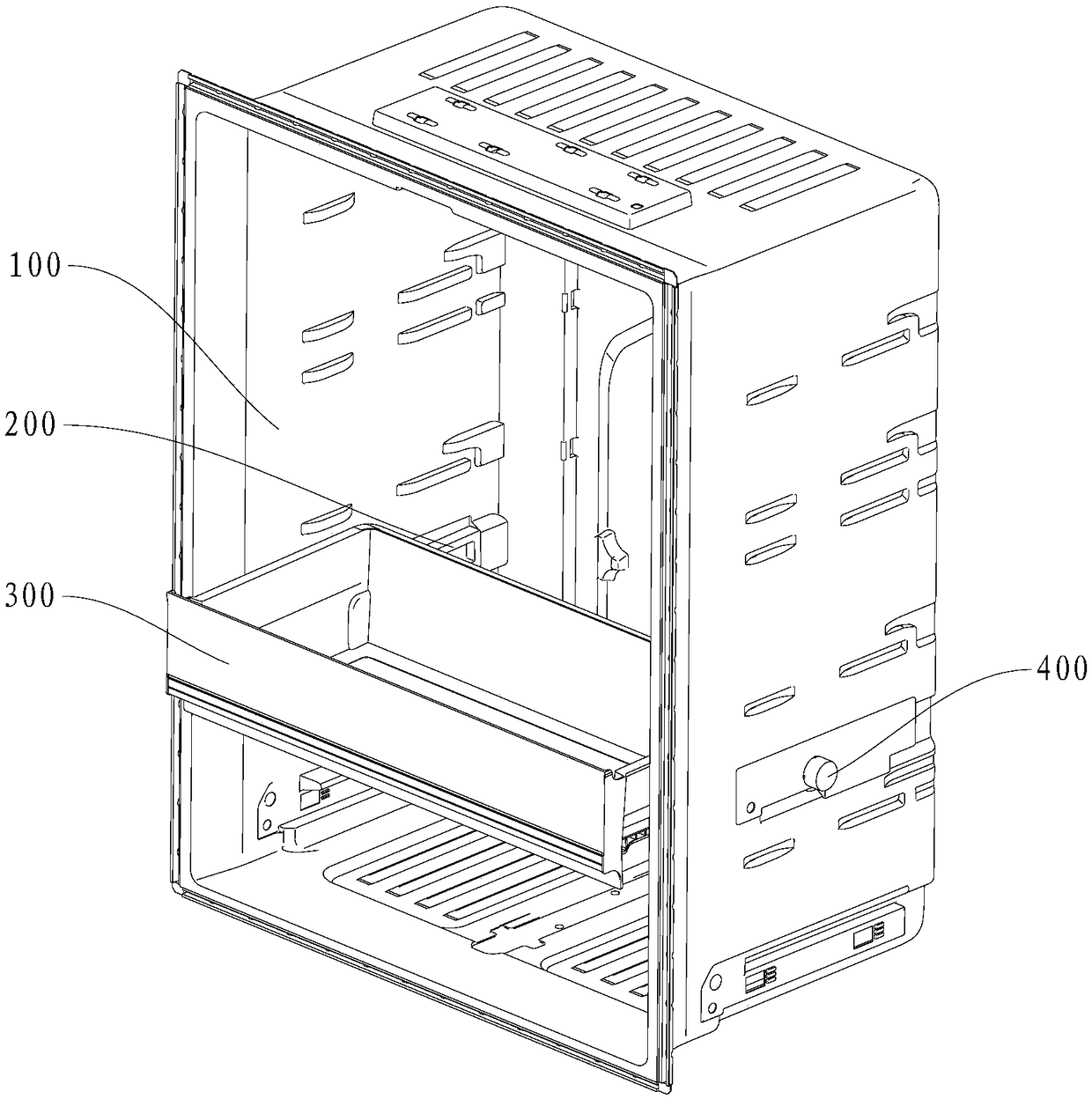

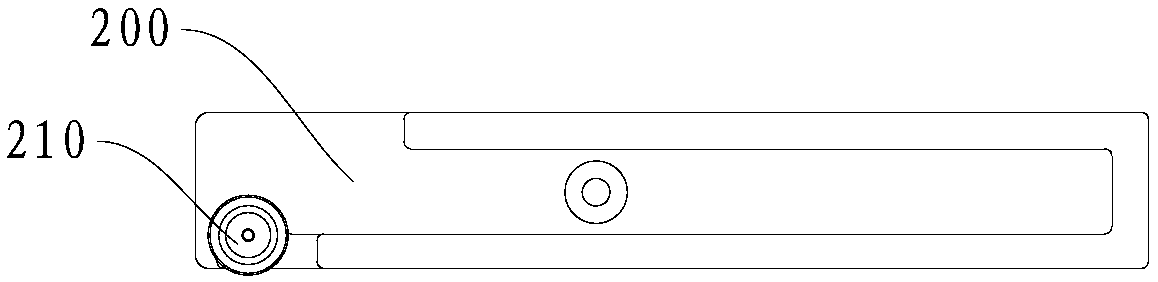

[0034] refer to Figure 2-Figure 6 , the drawer assembly in one embodiment of the present invention includes a sliding guide rail 200 , a drawer 300 assembled with the sliding guide rail 200 , and a guide rail bracket for supporting the sliding guide rail 200 . In this example, if Figure 4 , the guide rail bracket is the bile rib 110 arranged on the box body 100 . Wherein, there is a certain gap in the vertical direction between the sliding guide rail 200 and the guide rail support. refer to Figure 4 and Figure 5 A rotating mechanism 400 is provided between the box body 100 and the sliding guide rail 200 , and the sliding guide rail 200 is vertically rotatably connected with the box body 100 through the rotating mechanism 400 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com