A method for manufacturing a telephoto off-axis paraboloid with a large off-axis amount

An off-axis parabola and manufacturing method technology, which is applied in the field of optics, can solve the problems of low detection accuracy and poor processing accuracy of off-axis paraboloids with a large off-axis amount in telephoto

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

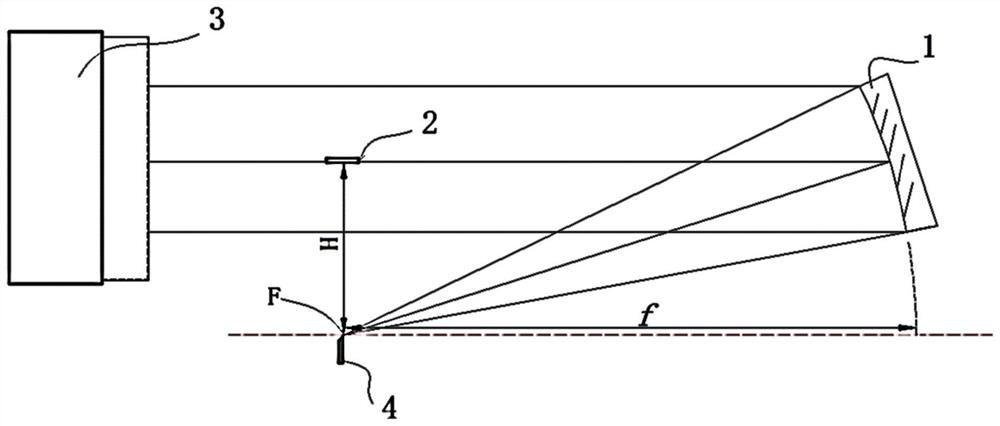

[0034] Taking an off-axis parabolic mirror with a diameter of D1=Ф400mm, a thickness of 60mm, a back focal length of f=18m, and an off-axis distance of H=9m as an example, a detection optical path of a long-focus off-axis paraboloid with a large off-axis distance, such as Image 6 As shown, along the propagation direction of the light waves emitted by the interferometer 5 are arranged in sequence: a diverging lens 8, a standard spherical reflector 6, and a standard plane reflector 7. The divergent lens modulates the light waves emitted by the interferometer into a divergent spherical surface The divergent spherical wave is reflected by the standard spherical mirror and incident on the measured telephoto large off-axis paraboloid 1, and the light wave reflected by the measured telephoto large off-axis paraboloid is a plane wave, and the plane wave is vertical Return to the original path after incident on the standard plane mirror;

[0035] The standard spherical reflector and t...

Embodiment 2

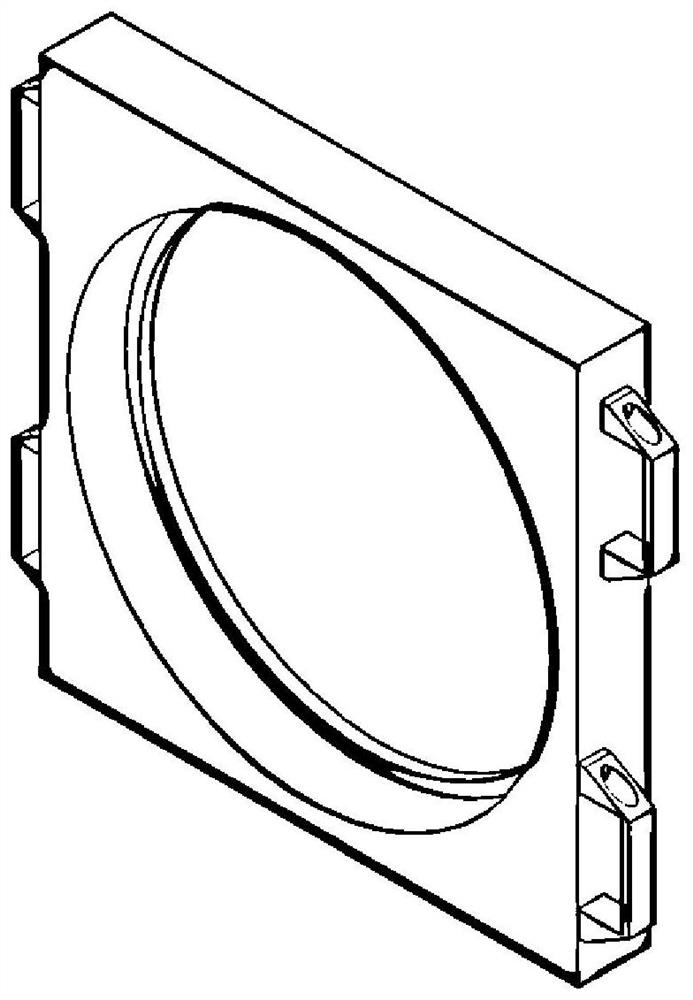

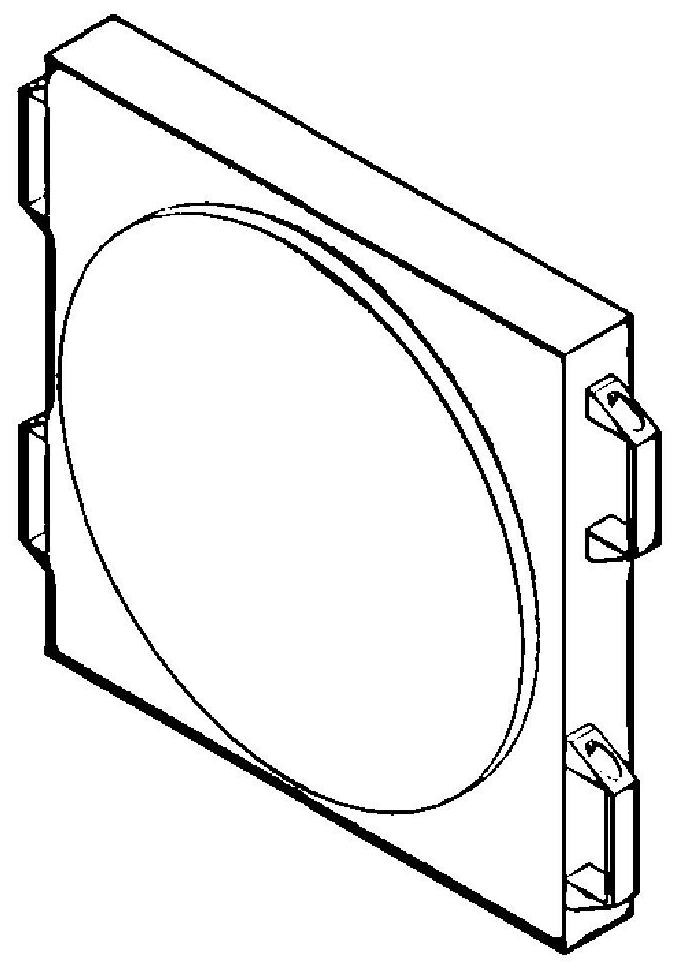

[0041] combined with figure 1 , taking an off-axis parabolic reflector with a processing diameter of D1=Ф400mm, a thickness of 60mm, a back focal length of f=18m, and an off-axis amount of H=9m as an example, a manufacturing method of a telephoto off-axis paraboloid with a large off-axis amount:

[0042] Step 1: Design the off-axis two-mirror inspection system according to the parameters of the off-axis parabolic mirror, and use the ZEMAX program to optimize the design and obtain the optical path diagram as follows Figure 7 , it can be seen from the figure that the deflection angle θ1=14.9575°, the deflection angle θ2=-10.334°, the radius of the standard spherical mirror is R2=21650±300mm, the distance between the two mirrors is about d1=2500mm, the standard spherical mirror The image point distance from the center of the reflector to the two mirror systems is about d2=7500mm, the diameter of the standard spherical reflector is D2=Ф385mm, and the system image square F / # is F / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com