Cutting tool shock resistance test device

A technology for characteristic testing and impact resistance, which is applied in the direction of impact testing, measuring devices, and testing of machine/structural components. Intuitive and accurate, the effect of improving the service life of the cutter

Active Publication Date: 2019-01-18

CENT SOUTH UNIV

View PDF21 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The above-mentioned domestic research institutions have conducted research on the wear characteristics of cutting tools

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

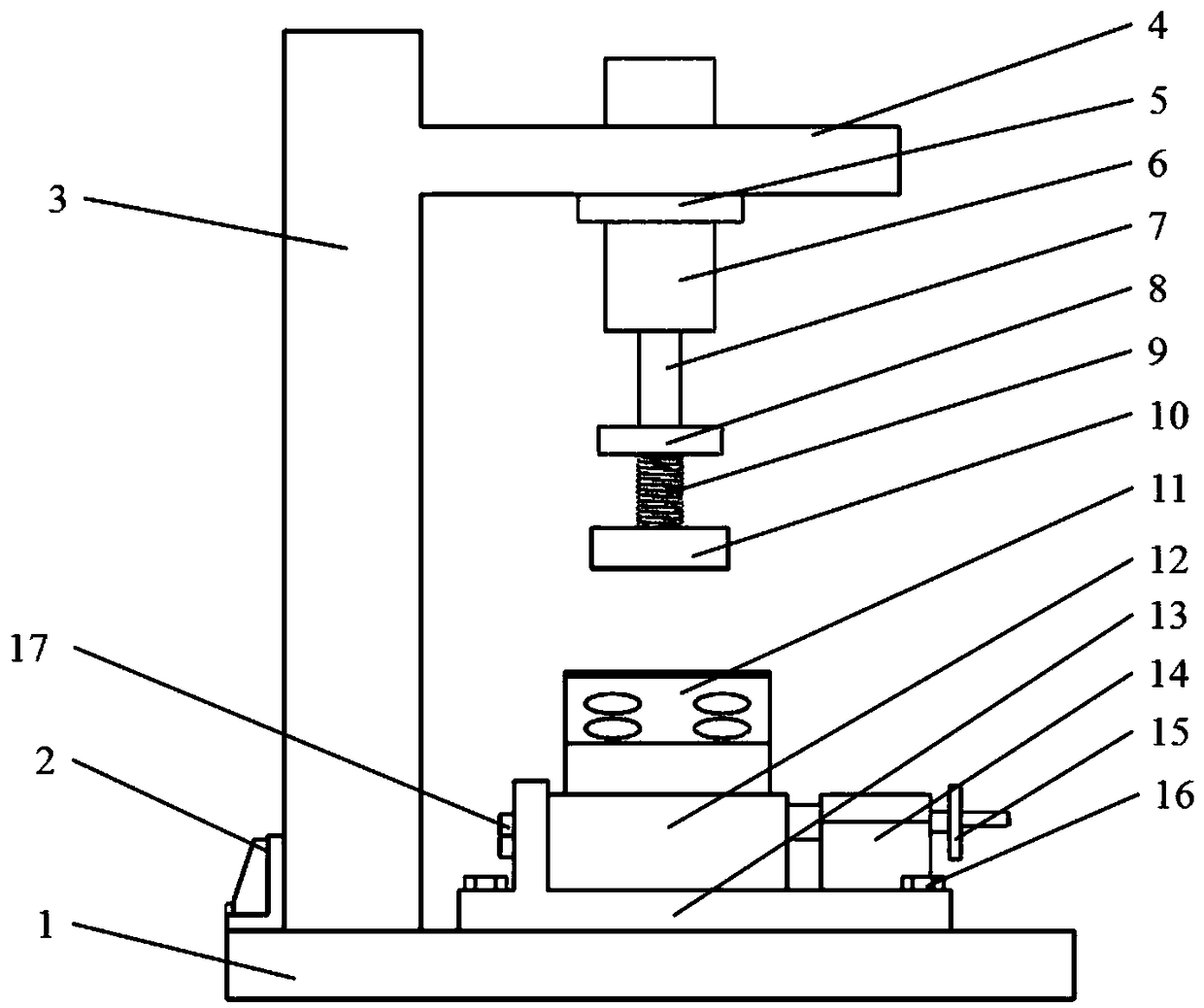

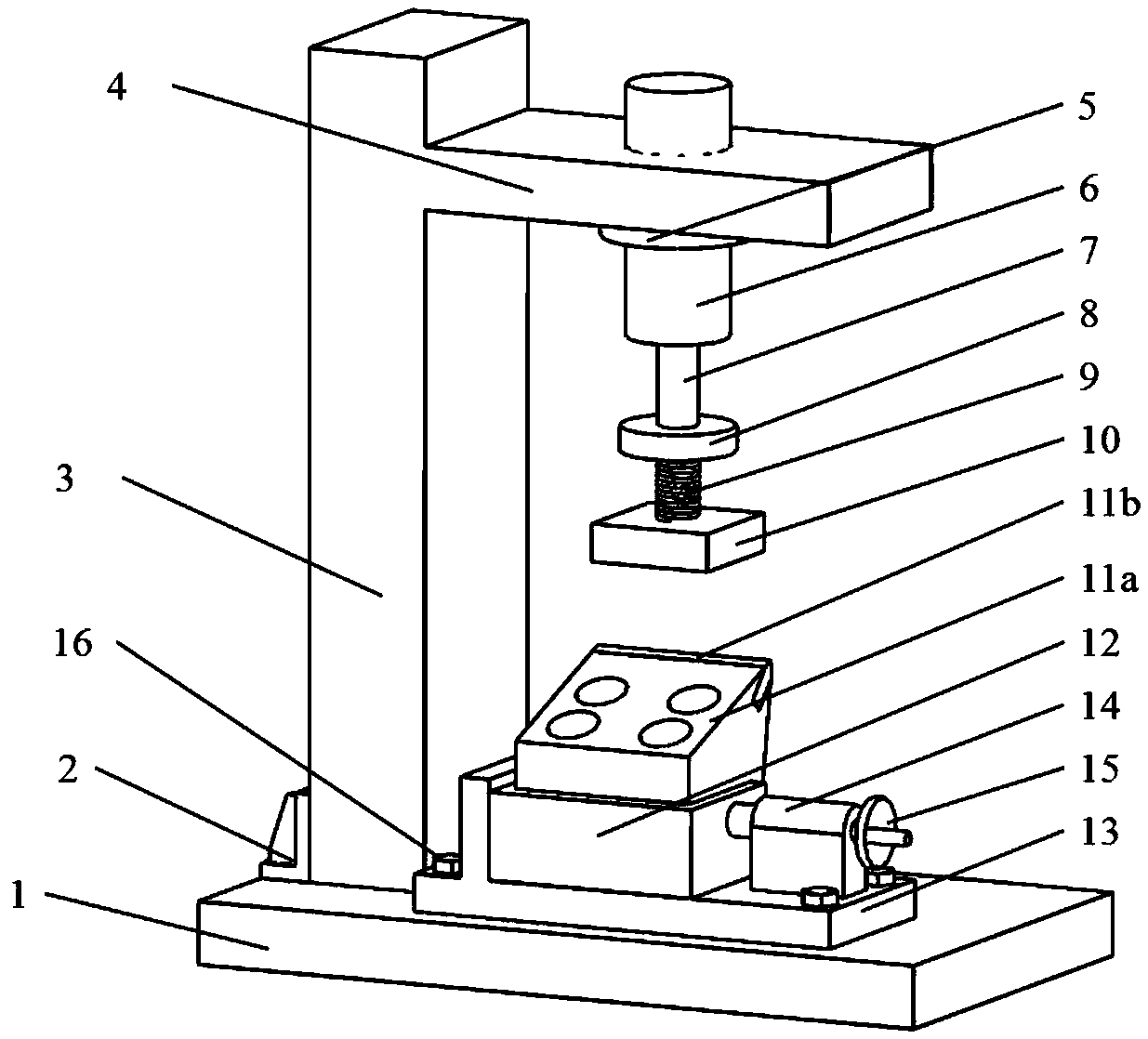

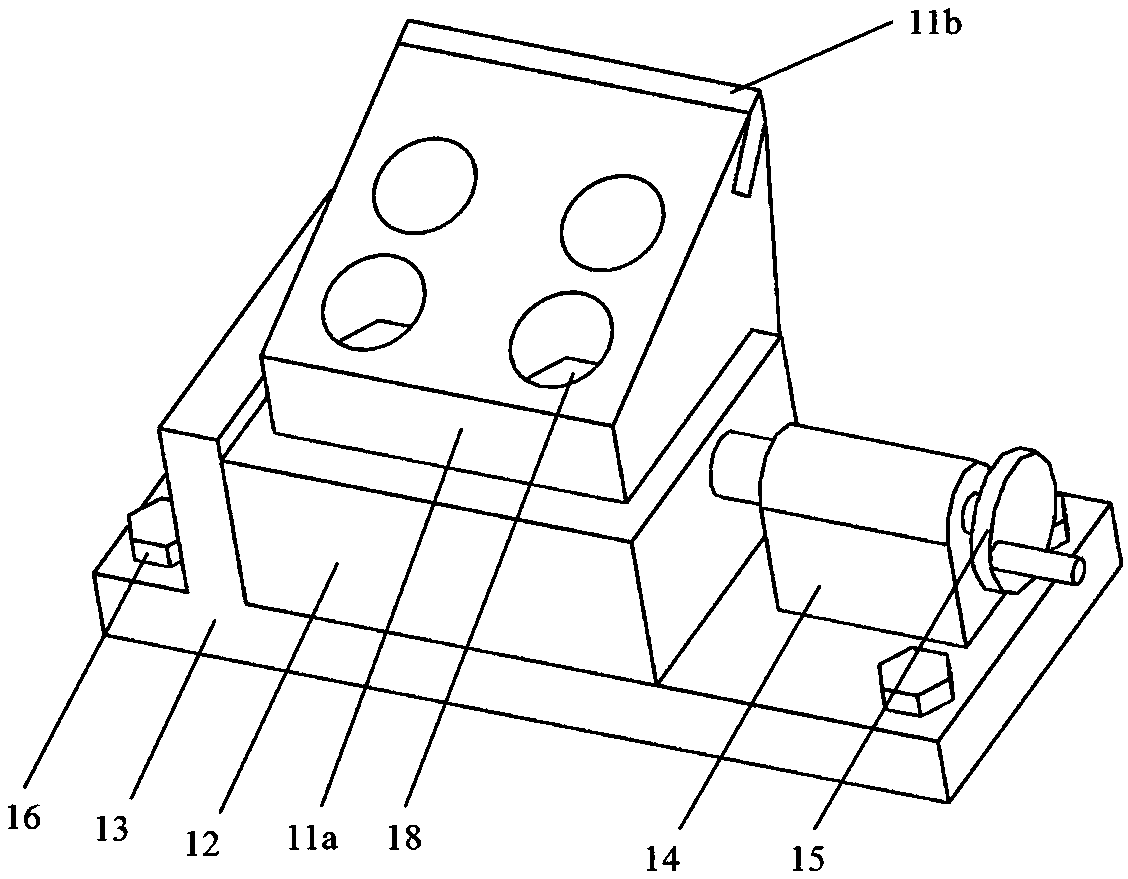

The invention discloses a cutting tool shock resistance test device used in the field of tunnel engineering. A cutting tool provided by the invention is mounted on a cutting tool mounting base, one side of the cutting tool mounting base is closely attached to a locating mounting base, the other side of the cutting tool mounting base is regulated through a rocker mechanism for realizing dismounting, the locating mounting base is connected with a pedestal, and a shock position of the cutting tool can be adjusted in a horizontal direction; a stand column is connected with the pedestal, the standcolumn supports a rib plate to realize reinforcing, an upper end of the stand column stretches out and forms one cross beam, a body of a servo hydraulic cylinder is fixed on the cross beam through a servo hydraulic cylinder flange, a piston rod is connected with a force transferring spring through a connection plate, the force transferring spring transfers shock load to a shock plate, and thus, shock operation is realized; and by adjusting shock stroke and shock frequency of the servo hydraulic cylinder and changing rigidity of the spring, shock force on the cutting tool under different tunneling working conditions (different geological conditions and different tunneling parameters) is simulated. A data acquisition card, a pressure sensor and a flow sensor are used for performing real-timemonitoring for a cutting tool shock test process. The cutting tool shock resistance test device provided by the invention can simulate the cutting tool shock processes under different working conditions, explore cutting tool shock mechanisms and provide reference values for improvement of service life of the cutting tool.

Description

technical field [0001] The invention relates to the technical field of impact testing, in particular to an impact resistance characteristic testing device for shield tunneling tools used in tunnel engineering. Background technique [0002] The shield construction method is widely used in underground engineering construction due to its advantages of high efficiency, environmental protection, high degree of automation, and strong geological adaptability, and is the main construction method for tunnel excavation. As one of the key components of shield tunneling and excavation, the cutter is subjected to sudden loads and impacts, resulting in abnormal wear of the cutter, causing shutdown to detect the working status of the cutter and changing the cutter, which seriously affects the tunneling efficiency of the shield machine and greatly increases Tunneling costs. According to engineering data, the construction period and cost consumed by tool maintenance and replacement account ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M7/08

CPCG01M7/08

Inventor 杨妹夏婧怡仝磊傅杰夏毅敏

Owner CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com