Air extraction device

A technology of exhaust device and exhaust pipe, which is applied in the direction of smoke removal, separation of dispersed particles, chemical instruments and methods, etc., and can solve the problems of intermittent adjustment and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

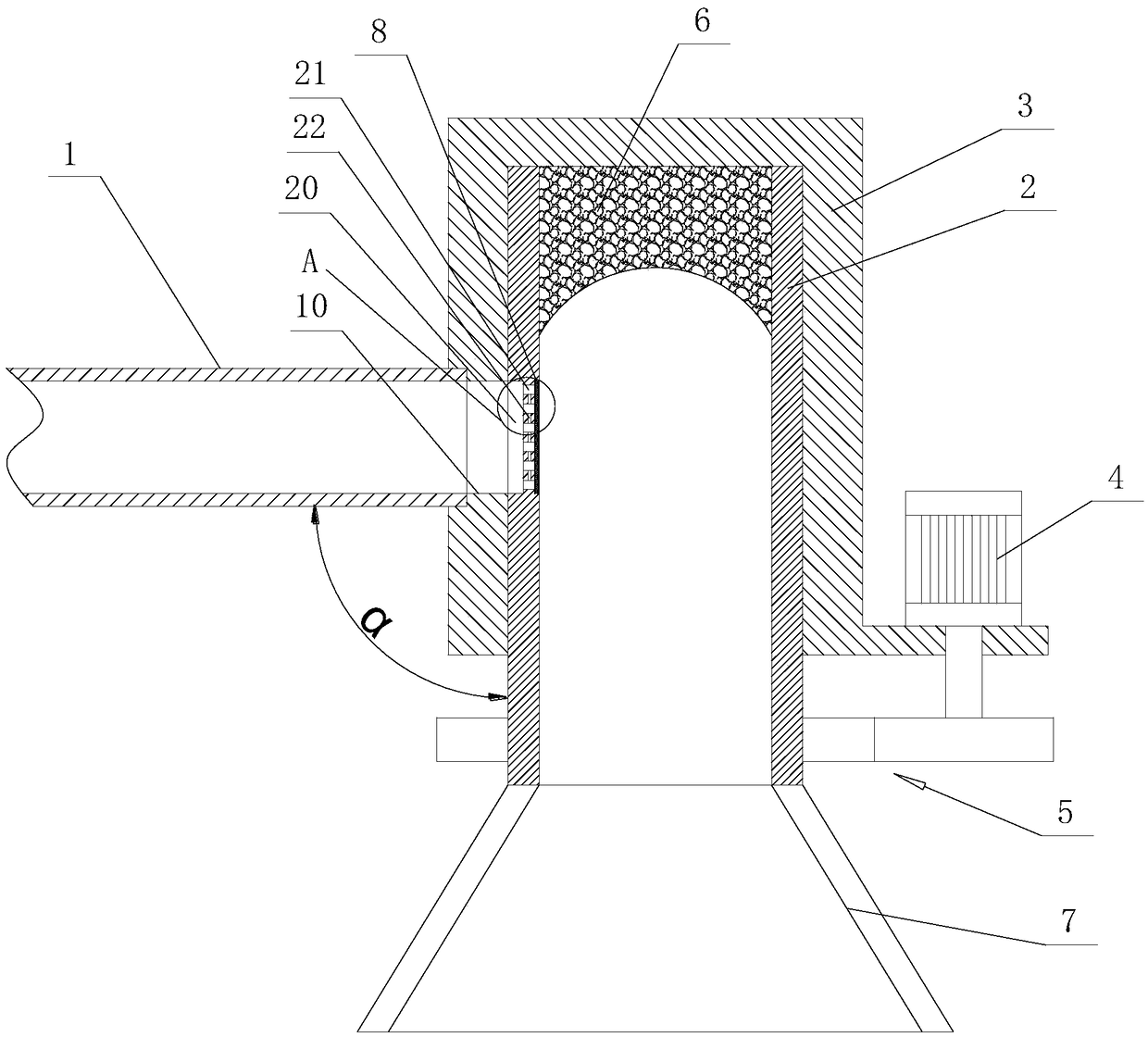

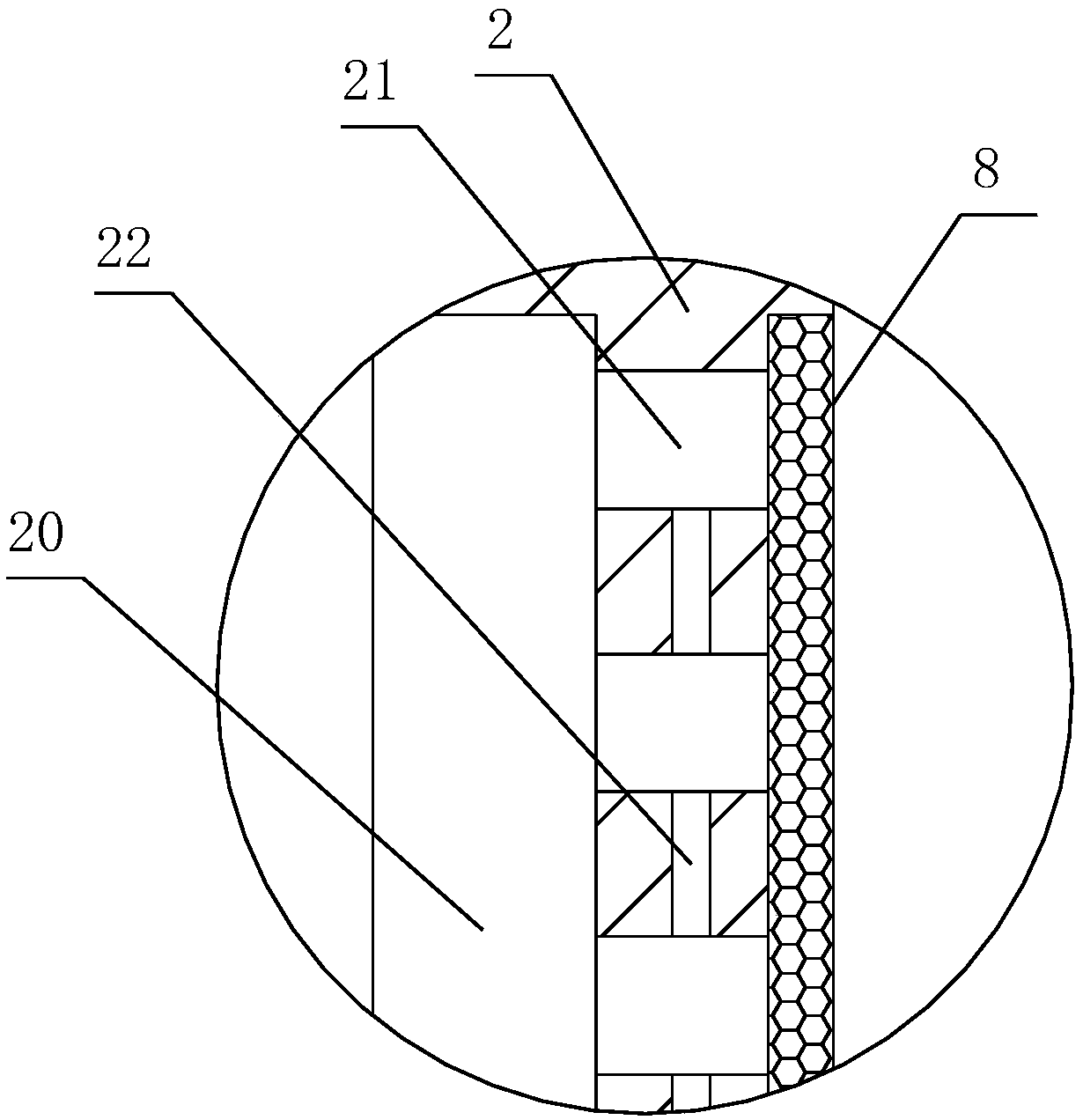

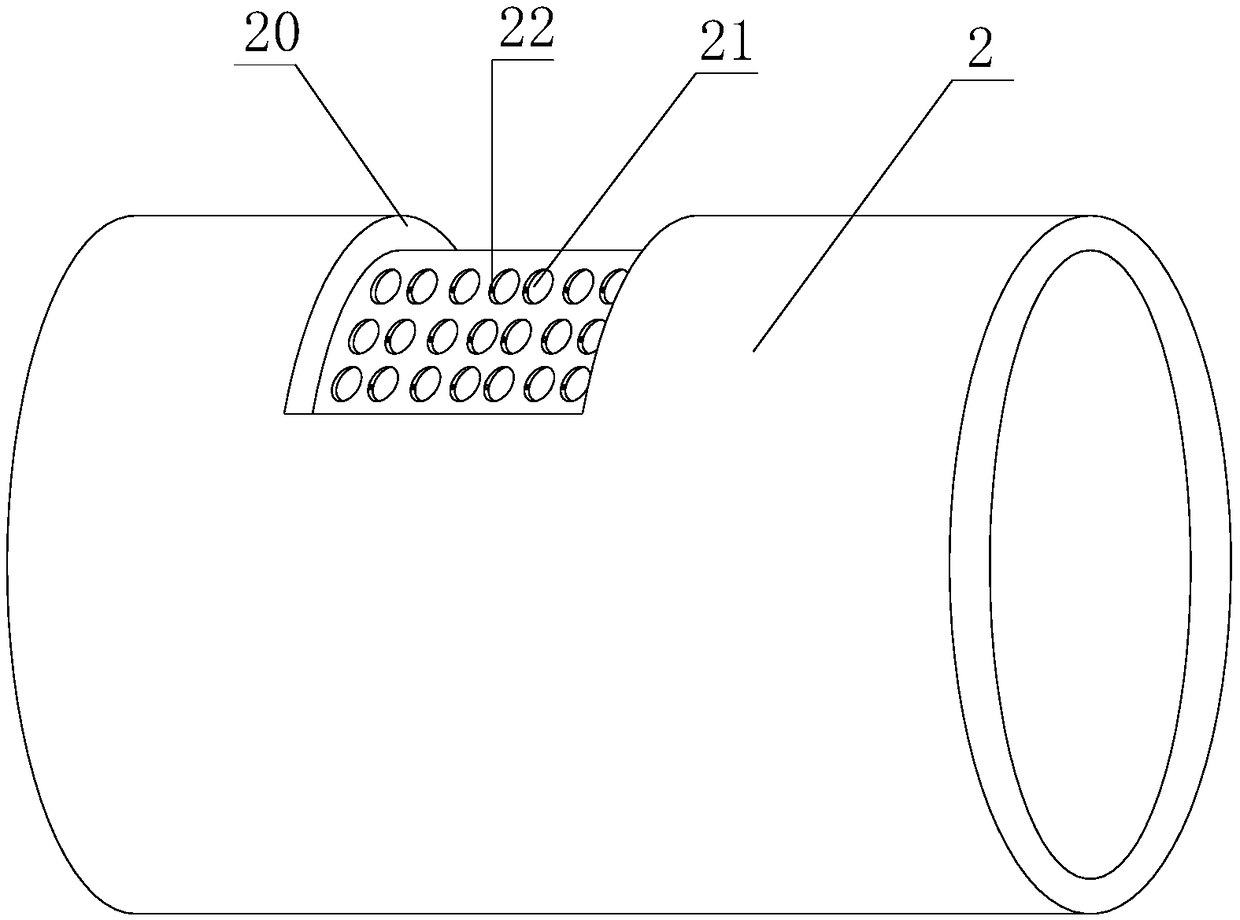

[0021] Such as Figure 1-3 A ventilation device is shown, including a first ventilation pipe 1, a second ventilation pipe 2, and a base 3;

[0022] The second exhaust pipe 2 is rotationally connected with the base 3, and the base 3 is provided with a connecting blind hole. One end connected to the base 3 is sealed, and the second exhaust pipe 2 is liquid-tightly matched with the base 3;

[0023] The base 1 is provided with a ventilation hole 10, an angle α is formed between the ventilation hole 10 and the second exhaust pipe 2, and α=90°; the lower end of the second exhaust pipe 2 extends out of the base 3, and the driving mechanism is used To drive the second exhaust pipe 2 to rotate, the second exhaust pipe 2 has a channel that communicates with the ventilation hole 10 and the second exhaust pipe 2 when it rotates;

[0024] The first exhaust pipe 1 communicates with the ventilation hole 10;

[0025] During the working process of this embodiment, an exhaust fan is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com