Optical material refractive index homogeneity evaluation method

A technology of optical materials and evaluation methods, which is applied in the field of evaluation of refractive index uniformity of optical materials, can solve the problems of insufficient test information, few mathematical calculation processing relationships, and inconsistency with actual conditions, and achieves reliable refractive index uniformity indicators. , the effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

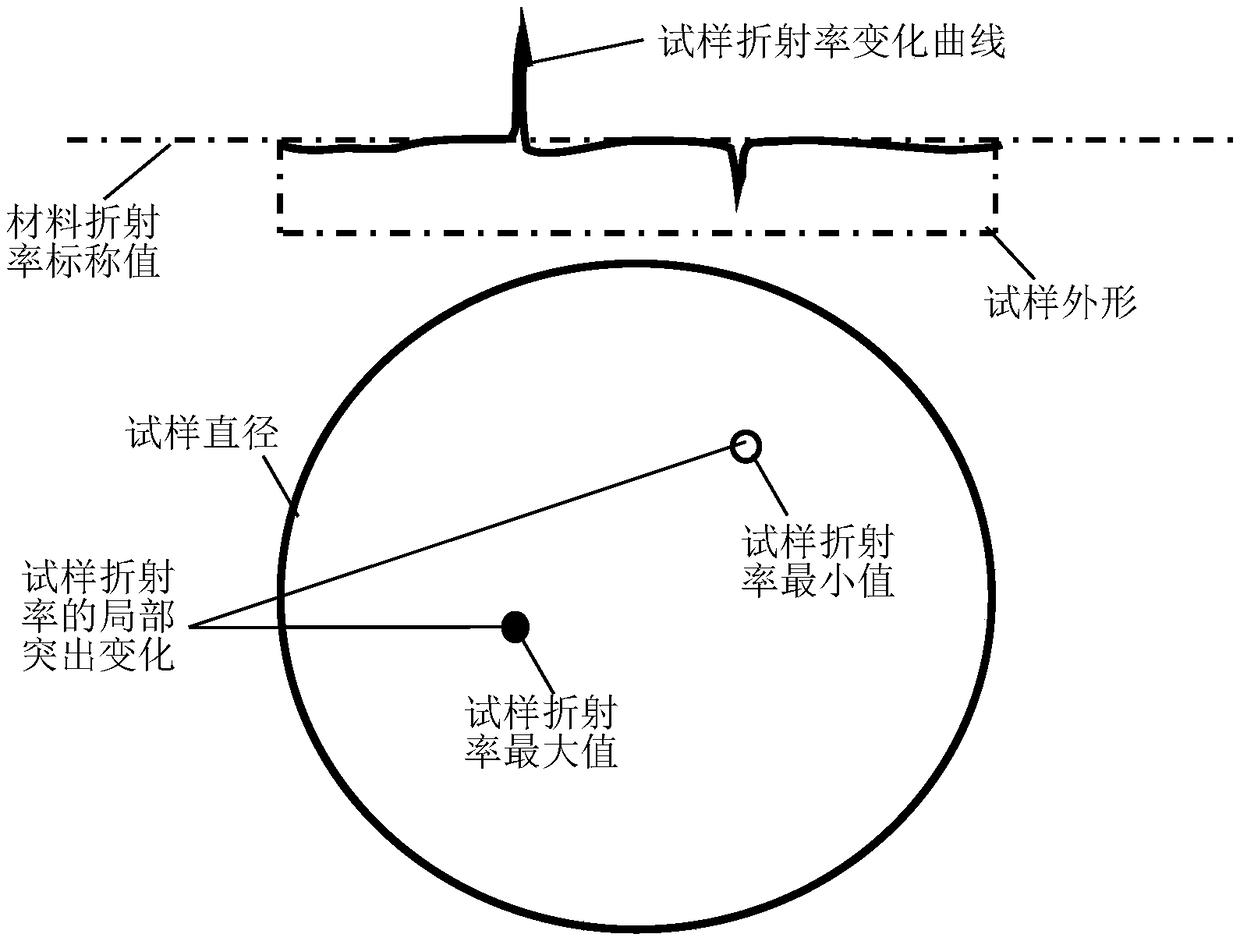

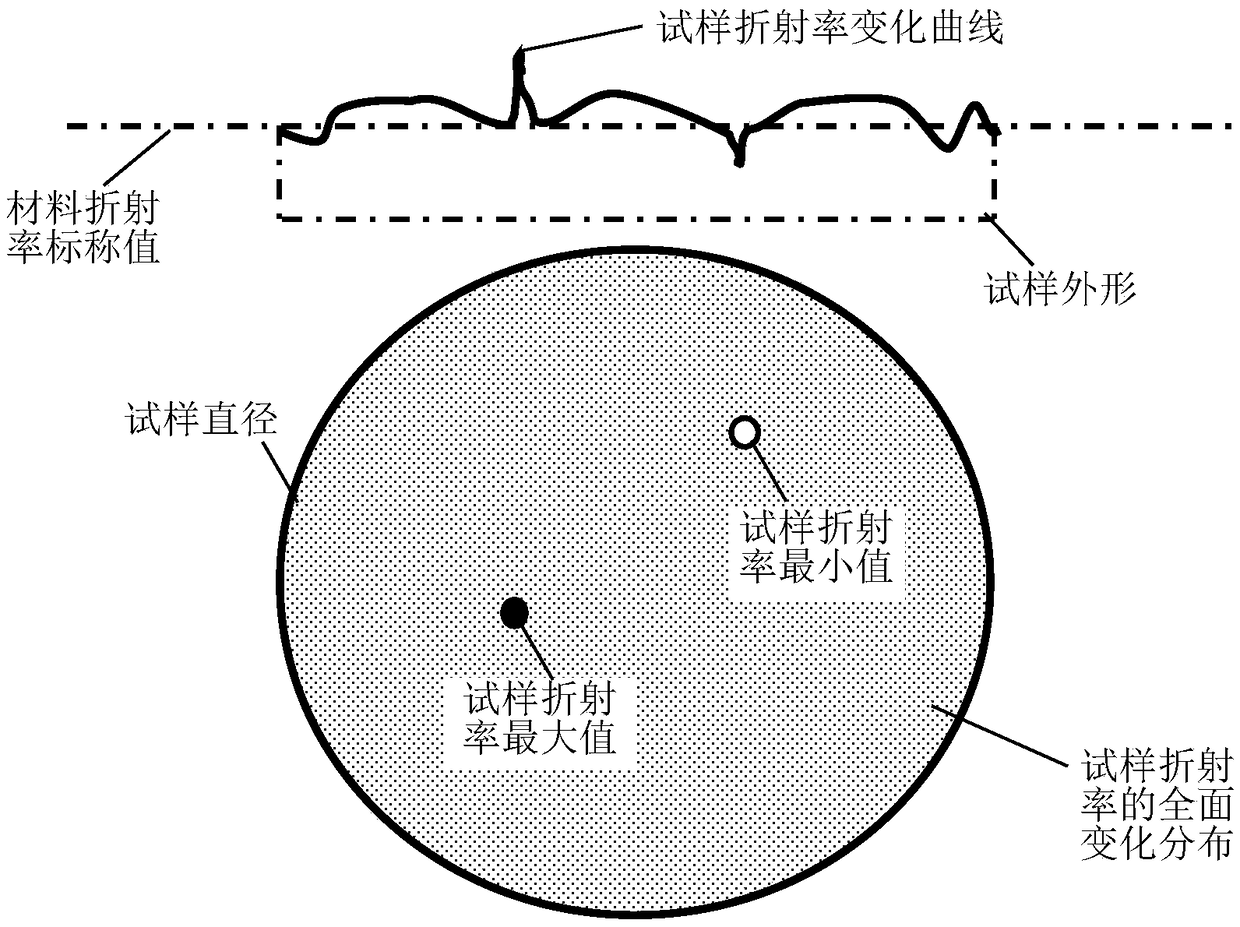

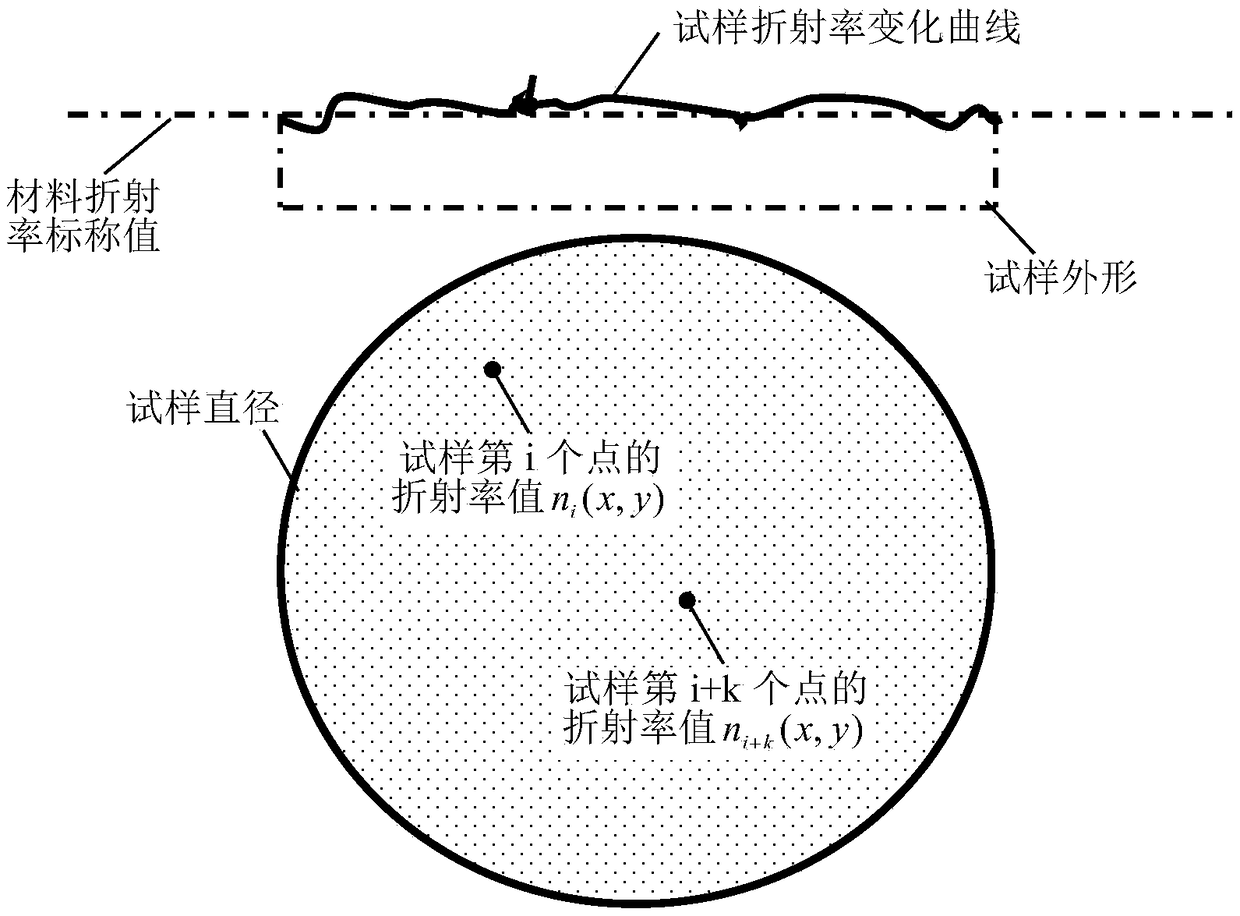

[0041] The inventors of the present invention have found that the statistics of the refractive index of each distribution point or surface element on the surface of the optical material is used to calculate the variation Δn of each point relative to the nominal value of the refractive index i (x, y), calculate the standard deviation value Δn of the refractive index change at each point STD , and then calculate the average value of the standard deviation of the refractive index change for multiple tests Taking this as the evaluation value of the uniformity of the refractive index of the optical material can fully reflect the actual impact of the uniformity of the entire surface of the optical material on the imaging qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com