Valve for controlling a fluid

A technology for controlling fluids and shells, which is applied in the direction of lift valves, multi-way valves, valve devices, etc., and can solve problems such as insulation layer material weakening, short circuit, etc., and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

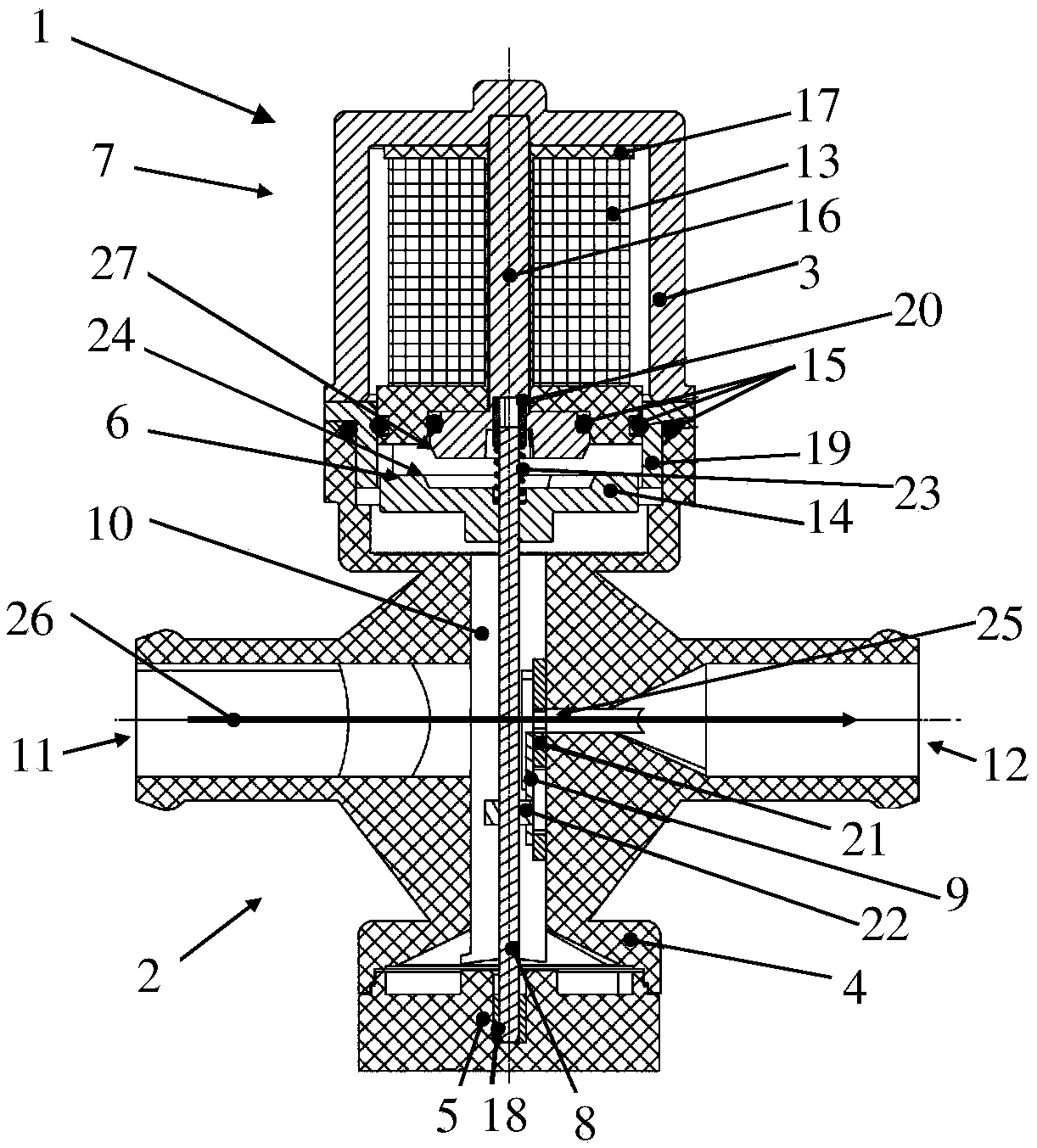

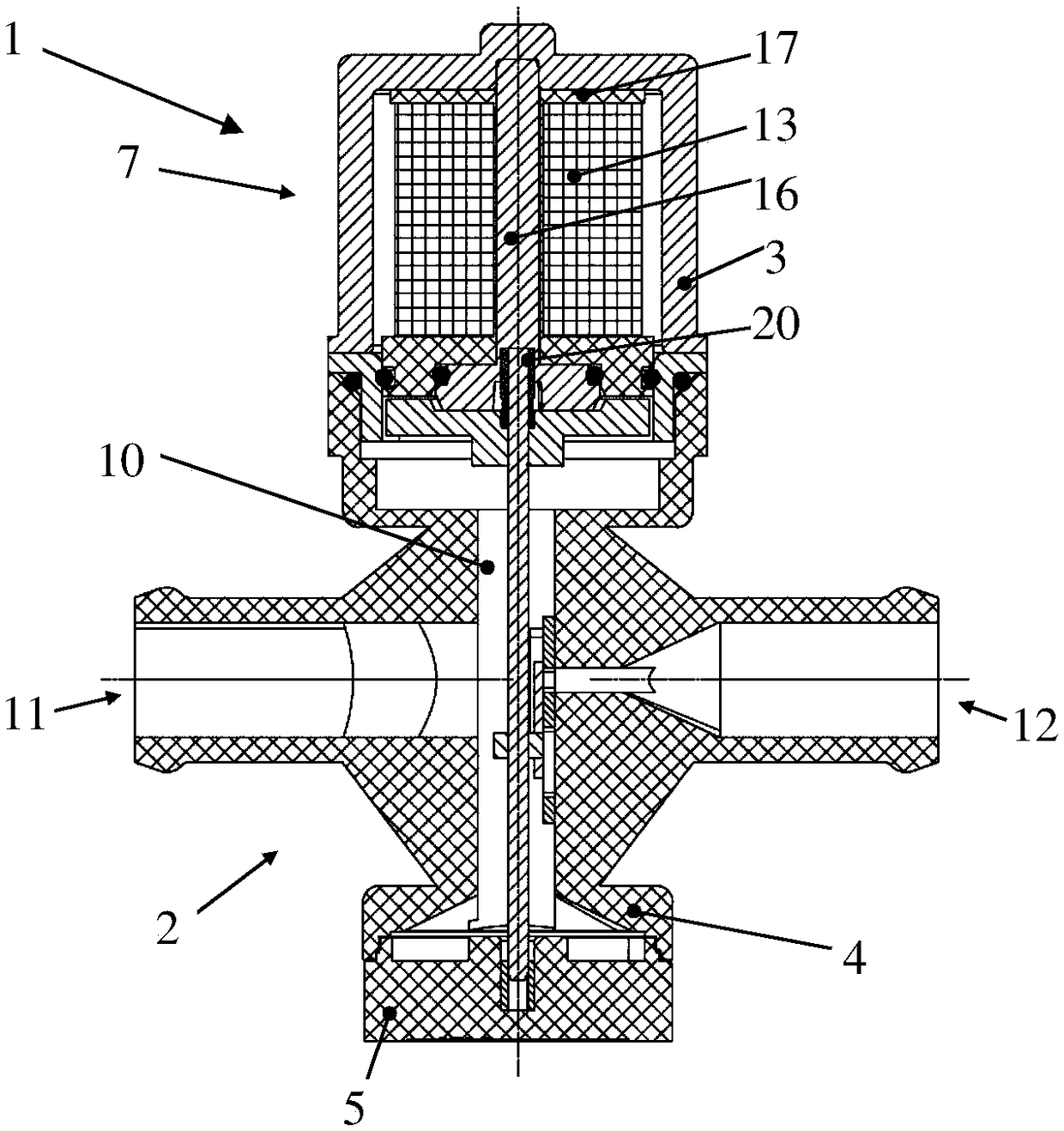

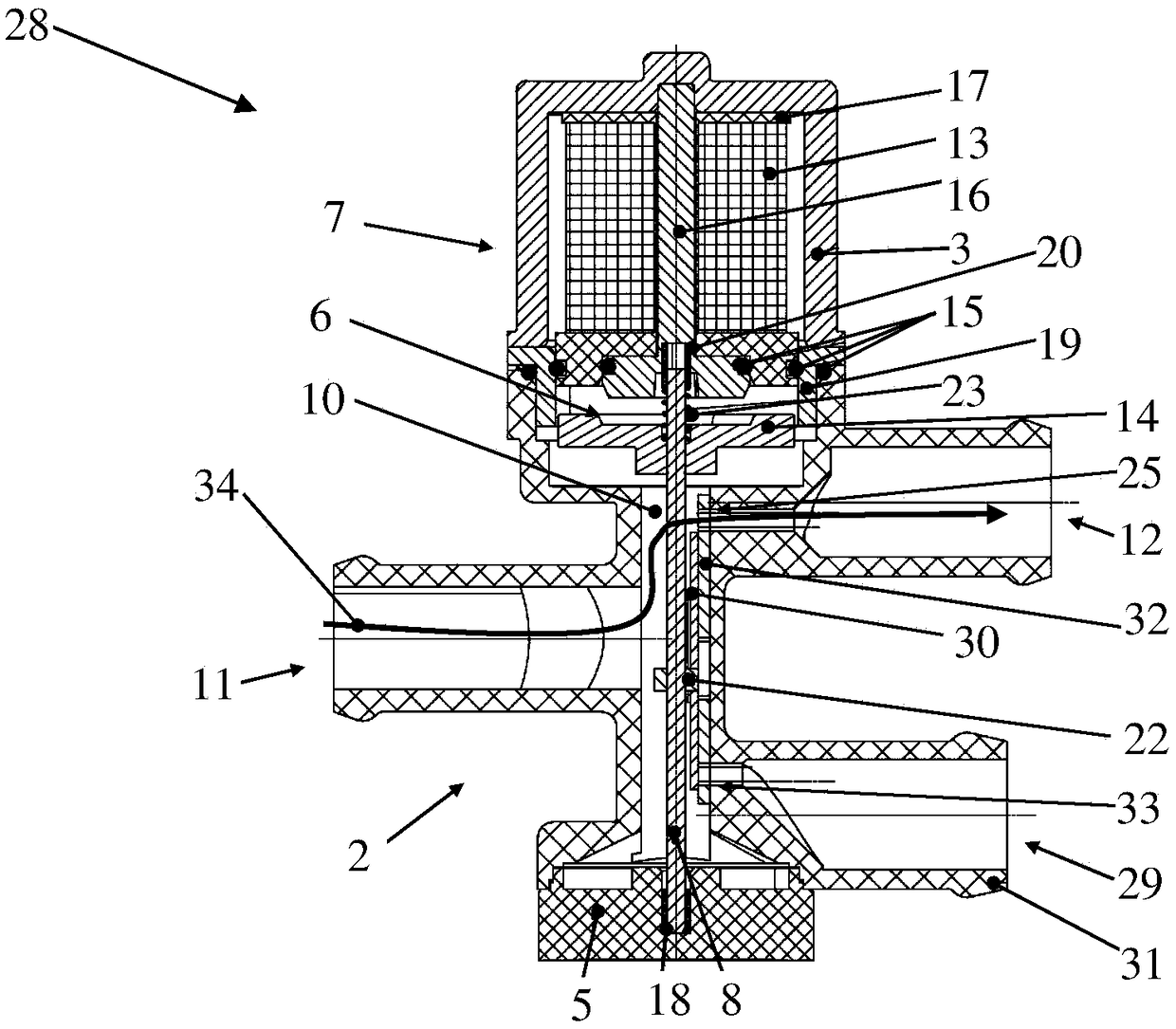

[0027] figure 1 and 2 A first embodiment of a valve 1 for controlling fluids according to the invention is shown in a side sectional view. The valve 1 comprises a housing 2 and an actuation unit 7 . The actuating unit 7 comprises a coil housing 3 connected to the housing 2 via a flange 19 , a coil 13 arranged in the coil housing 3 , a coil body 17 , an iron core 16 , a sliding sleeve 20 and an armature 14 . The coil 13 is surrounded by a coil body 17 and can be connected to a power source by a cable not shown. The coil 13 surrounds a core 16 which is connected to the core housing 3 . The armature 14 is disk-shaped and has a circular projection 6 , wherein a cone is formed on the circular projection 6 at its jacket inner surface 24 .

[0028] The core 16 has a cone 27 at the end facing the armature 14 .

[0029] Arranged between housing 2 , flange 19 and core 16 are O-rings 15 which statically seal coil 13 from cavity 10 formed in housing 2 . This offers the advantage tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com