High parameter steam drum intermediate reheating system for waste incineration power generation

A waste incineration, high-parameter technology, applied in the direction of steam application, steam engine device, machine/engine, etc., can solve the difficulty of reheating temperature stability, corrosion of the heating surface of the intermediate reheater, and fluctuating flue gas temperature To achieve the effects of convenient temperature adjustment, reducing exhaust humidity, improving cycle thermal efficiency and power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

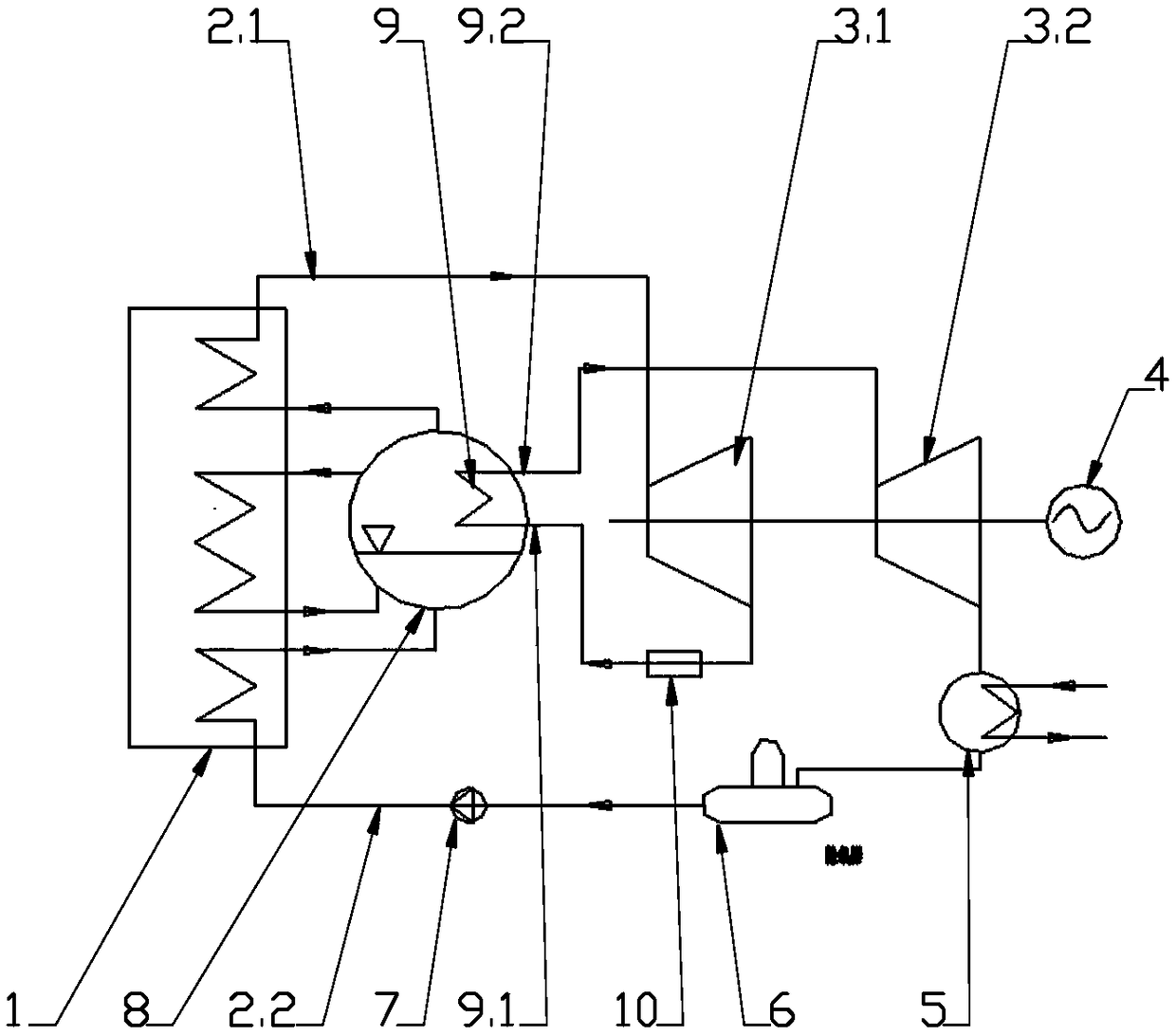

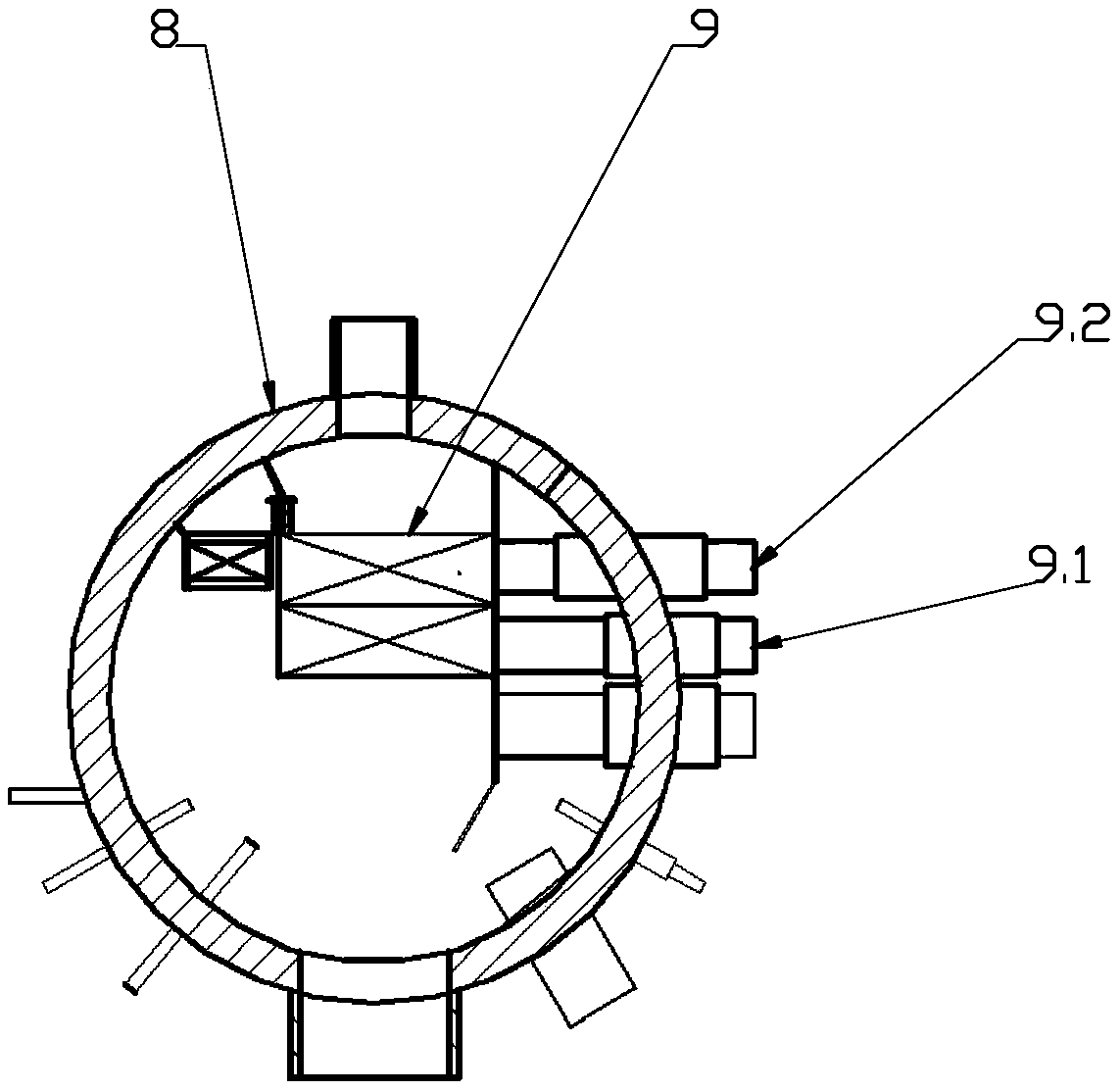

[0024] figure 1 , figure 2 It is a schematic diagram of an embodiment proposed by the present invention. in figure 1 layout drawing for equipment, figure 2 Schematic diagram of the installation layout of the intermediate reheater in the steam drum.

[0025] The figure shows that in this example, a high-parameter steam drum intermediate reheating system for waste incineration power generation includes a boiler 1, a steam drum 8, a steam turbine steam pressure cylinder, a generator 4, and a condenser 5 arranged in sequence according to the steam flow direction. And the pipeline 2.1 for conveying steam, including the deaerator 6, the feed water pump 7 and the feed water pipeline 2.2 arranged in order according to the flow direction of the feed water, the main steam generated by the boiler 1 enters the steam pressure cylinder of the steam turbine, drives it to do work and makes the generator 4 generate electricity, After the steam enters the condenser 5 from the steam pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com