Storage battery pull-out and transfer bracket assembly

A bracket assembly and battery technology, applied in the field of battery counterbalanced forklifts, can solve problems such as inconvenient charging management, easy sliding of batteries, and large area occupation, so as to save charging space, improve use safety, and reduce input costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

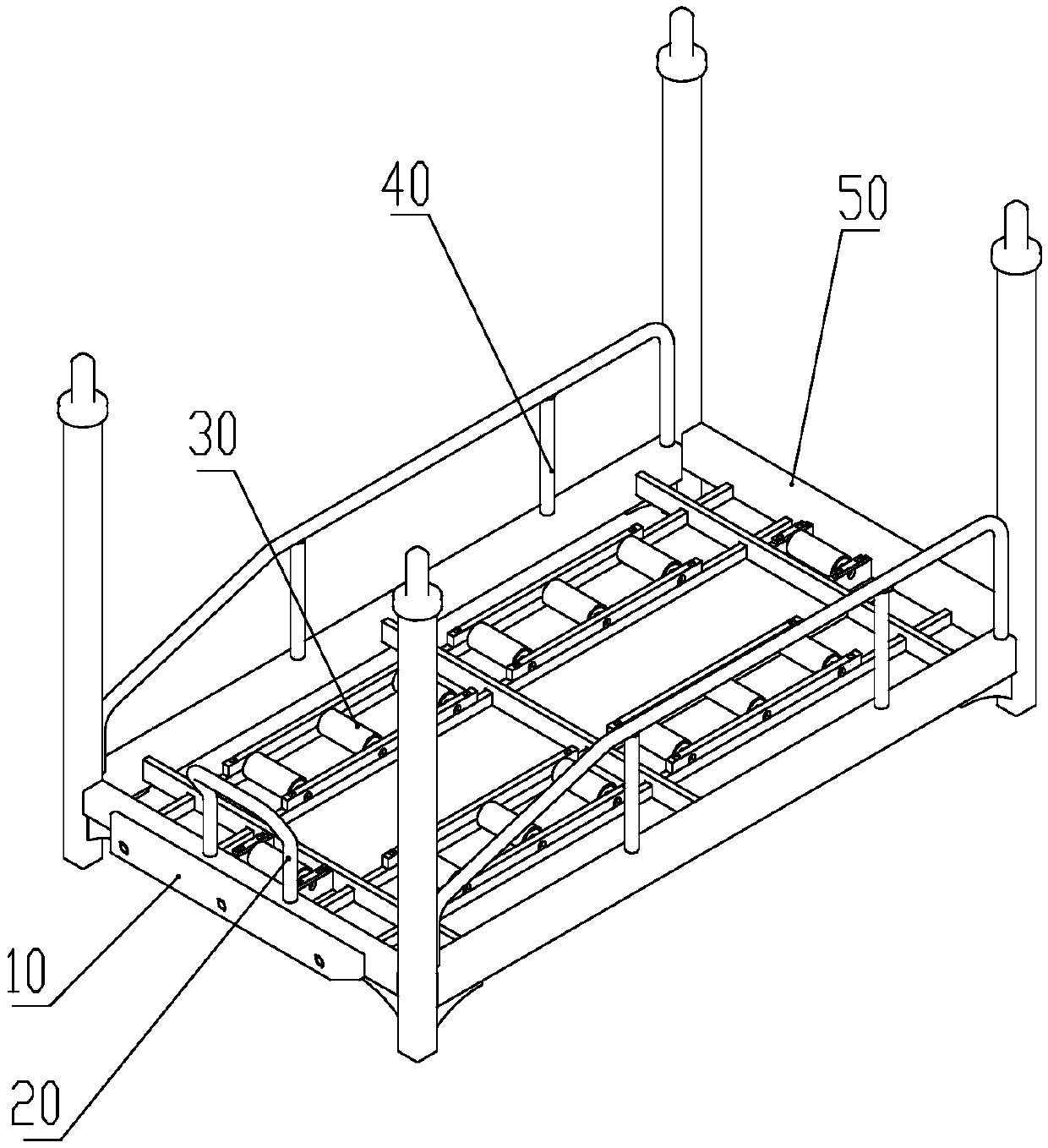

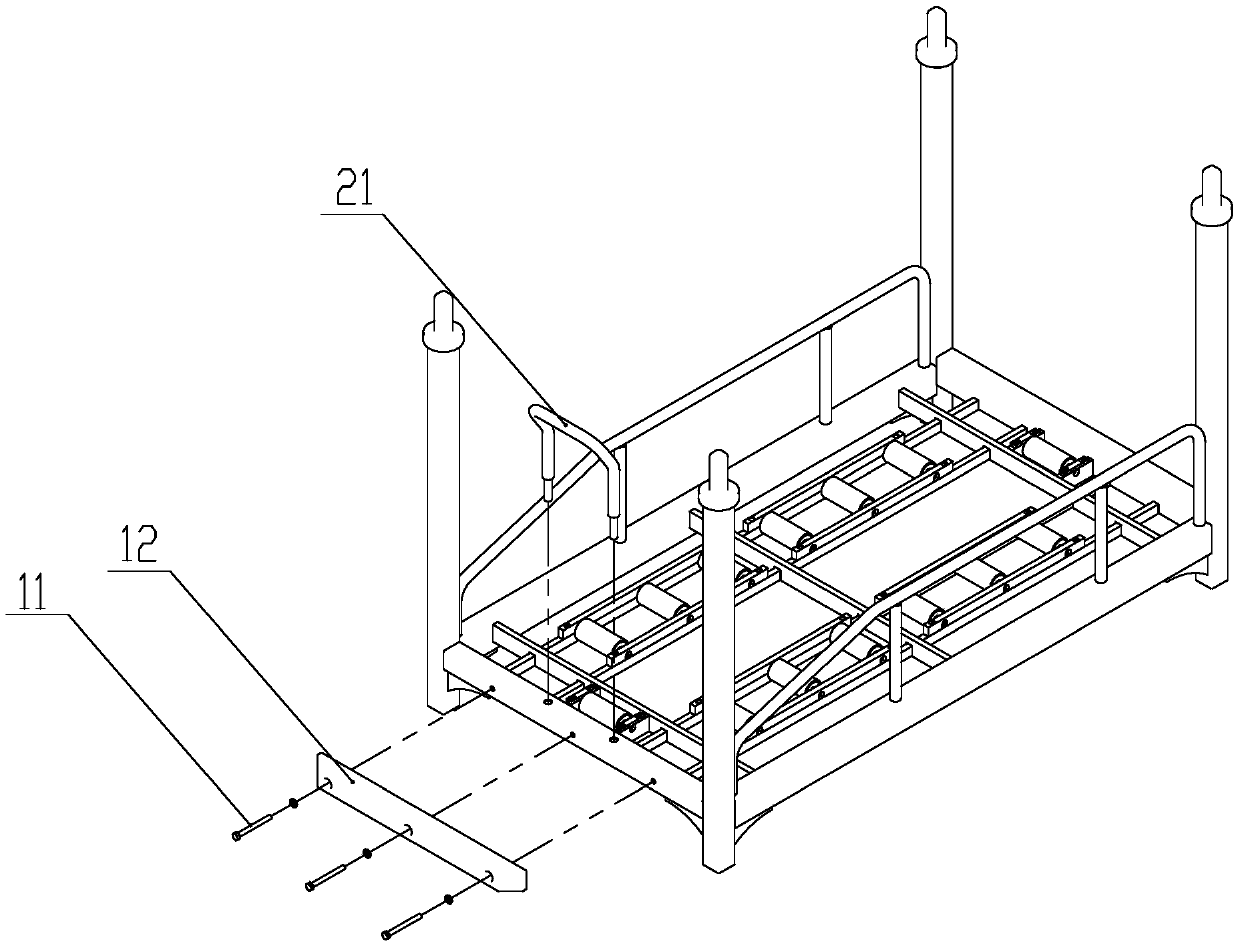

[0025] refer to Figure 1-8 , the present invention provides a battery pull-out and transfer bracket assembly, which consists of a front anti-collision structure 10, an anti-slip device 20, a middle battery support and raceway device 30, a side anti-slip guardrail 40, and a rear limit structure 50.

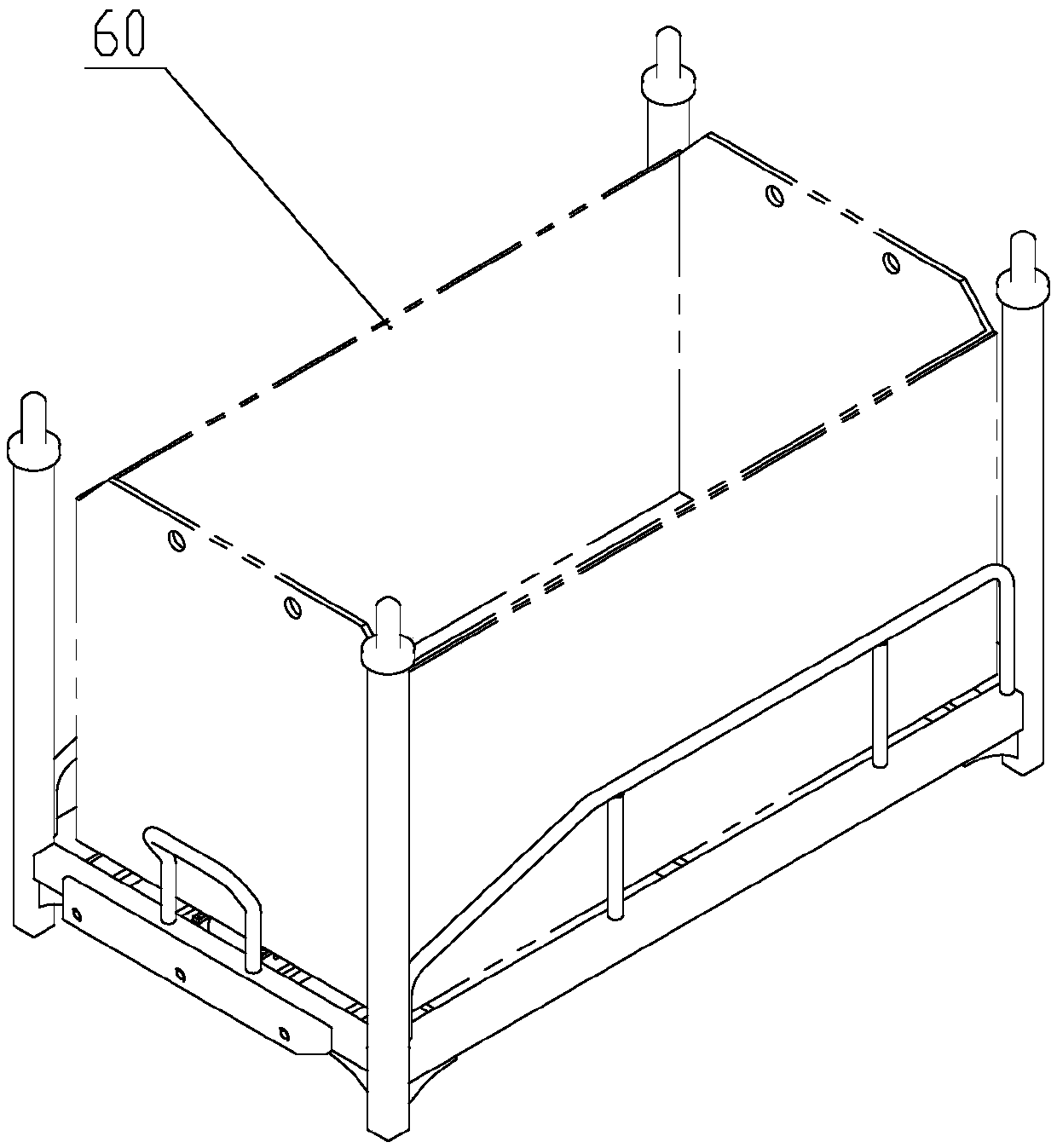

[0026] Such as figure 1 , figure 2 and Figure 8 As shown, the bracket assembly can complete the transfer, storage, and replacement of a single battery 60 , and can also use the vertical stacking of the bracket to realize storage and charging of multiple batteries 60 . Among them, the front anti-collision structure is used to reduce the impact between the bracket and the car body; the anti-sl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap