Insulation structure of the upper end of the deep-well grounding electrode

A grounding electrode and electrode insulation technology, applied in the direction of connection insulation, connection contact material, etc., can solve the problem that it is difficult to take out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0044] It should be understood that terms such as "having", "comprising" and "including" used herein do not exclude the presence or addition of one or more other elements or combinations thereof.

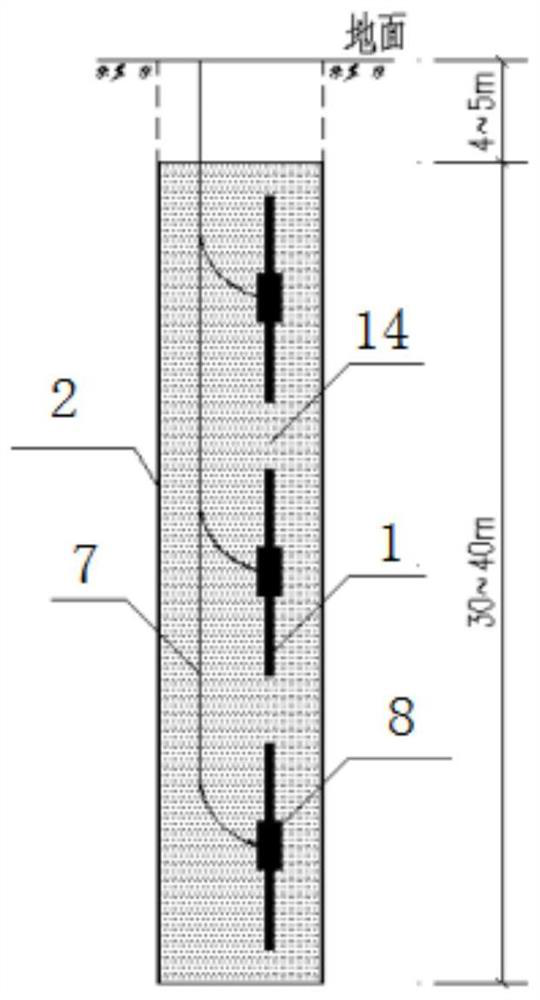

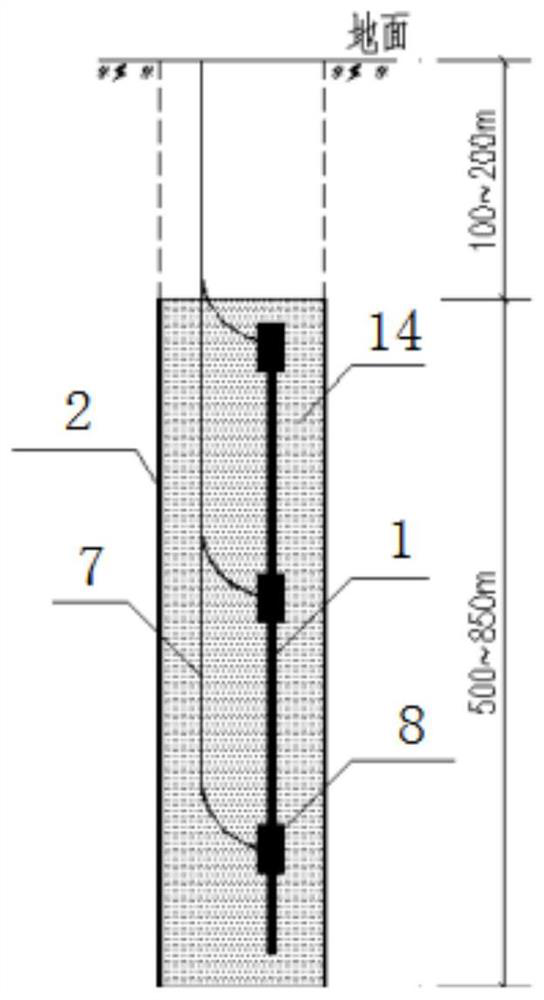

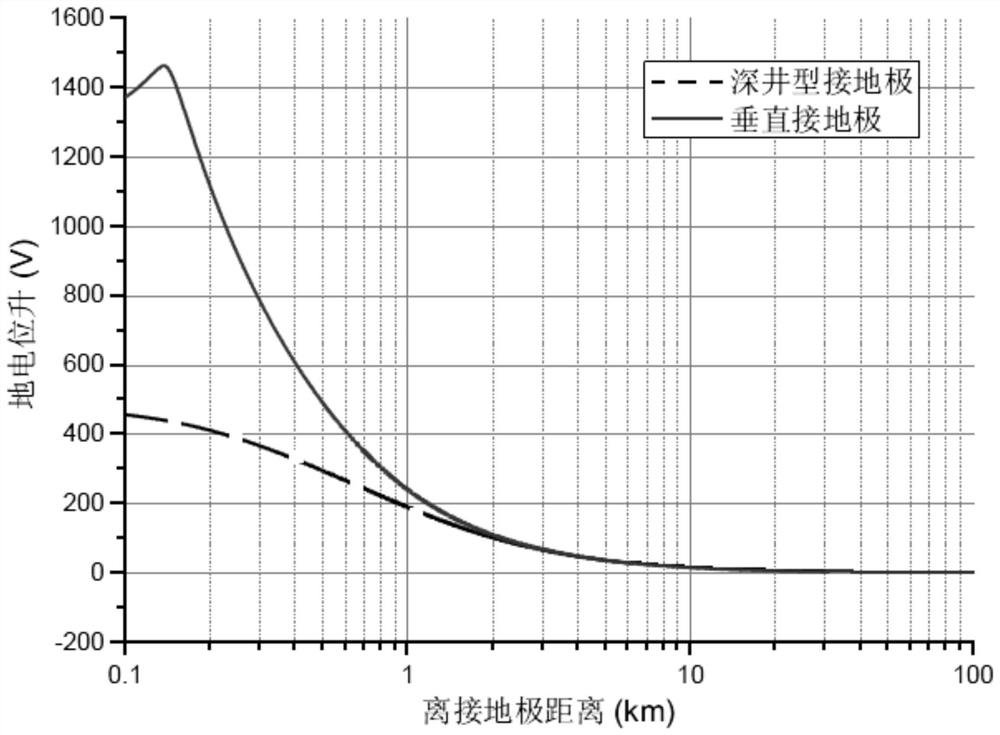

[0045]The deep well type grounding electrode is different from the ordinary vertical grounding electrode. In addition to the fewer number of pole wells and longer pole well length, the most important feature is that the designed buried depth of the electrode well can be deeper. Since the length of the electrode well of the vertical grounding electrode is generally about 30-40m, in order to make use of each section of the electrode well to disperse the flow, it should be buried as shallow as possible under the premise of meeting the step voltage. Generally, the top of the electrode w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com