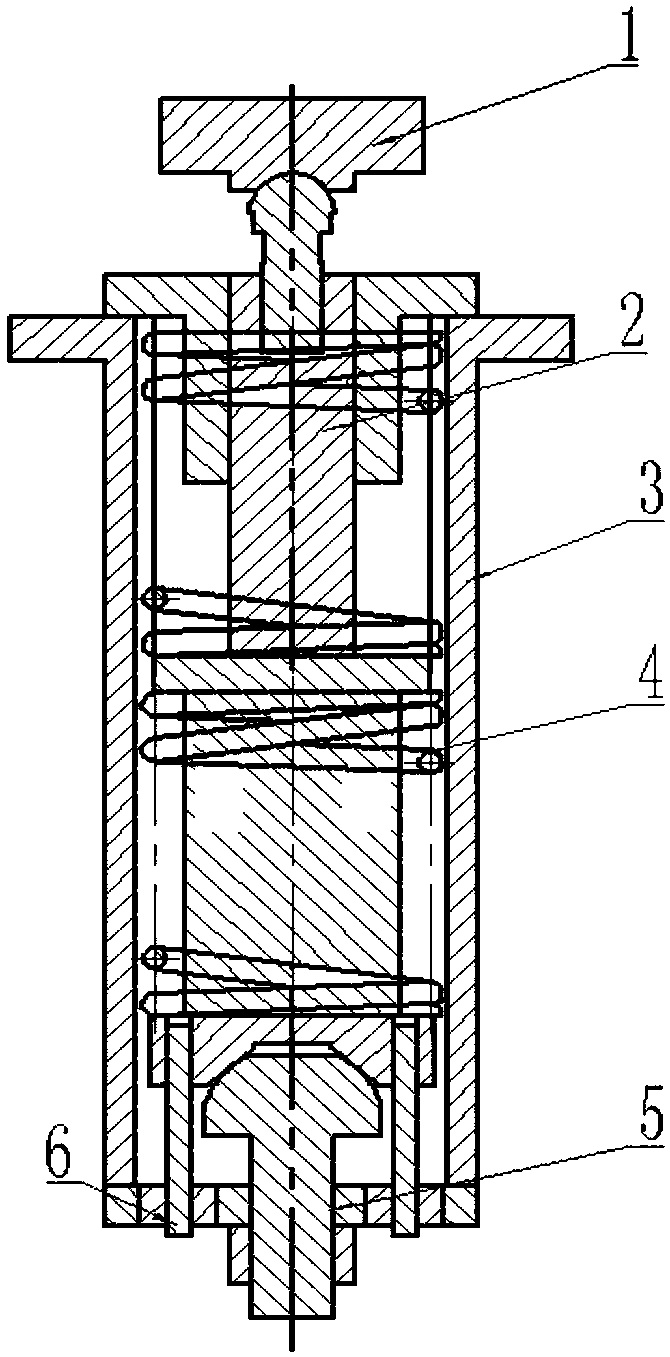

Telescopic positioning device

A technology of telescopic positioning and positioning components, which is applied in the direction of workpiece clamping devices and manufacturing tools, can solve the problems of precision optical-mechanical instrument adjustment position range, compression pre-tightening force can not effectively meet the design requirements, etc., to meet the adjustment and improve the accuracy , Improve the effect of installation and adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

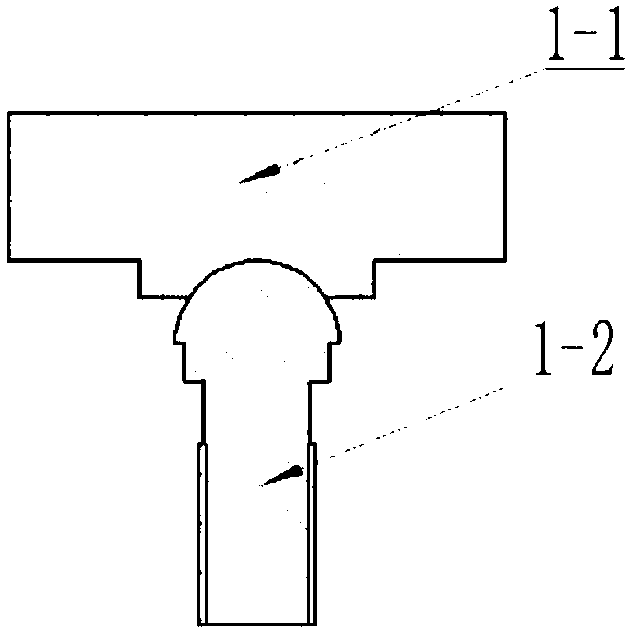

Examples

specific Embodiment approach

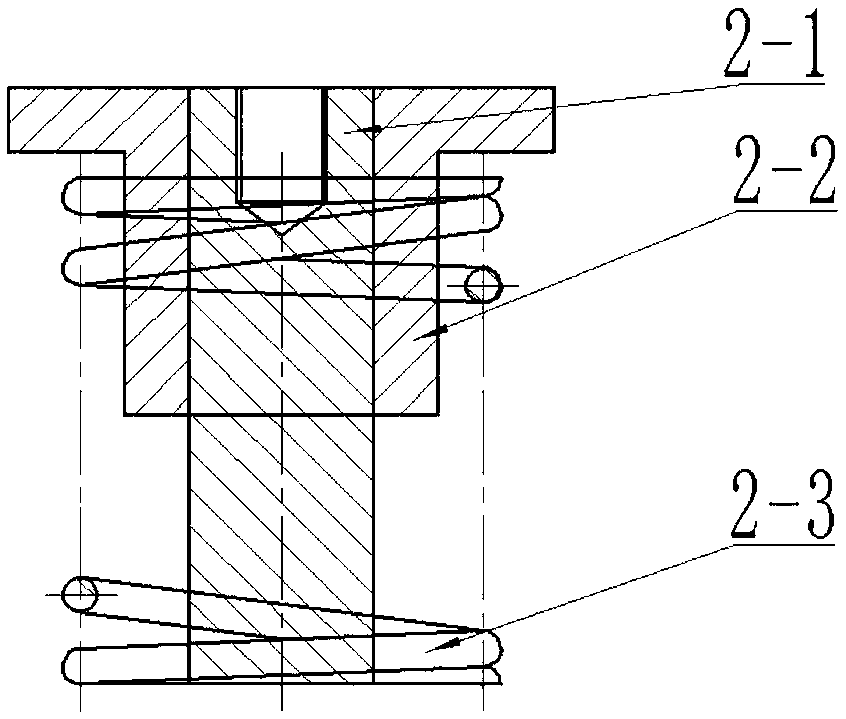

[0038] Further, see image 3 As shown, as a specific embodiment of the retractable positioning device provided by the present invention, the linear bearing assembly 2 includes a linear bearing rod 2-1, a linear bearing seat 2-2, and a compression spring 2-3. A flange is provided on the end surface of the linear bearing seat 2-2 to cooperate with the upper end surface of the outer shell 3, and a through hole is provided in the center of the linear bearing seat 2-2; the upper end of the compression spring 2-3 is connected to the inner side of the flange plate of the linear bearing seat 22 Connect, the lower end of compression spring 2-3 is connected with spring assembly 4. The top of the linear bearing rod 2-1 is provided with an internal thread to connect with the ball support assembly 1, and the bottom of the linear bearing rod 2-1 passes through the through hole of the linear bearing seat 2-2 to connect with the spring assembly 4; the linear bearing rod 2-1 can be The throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com