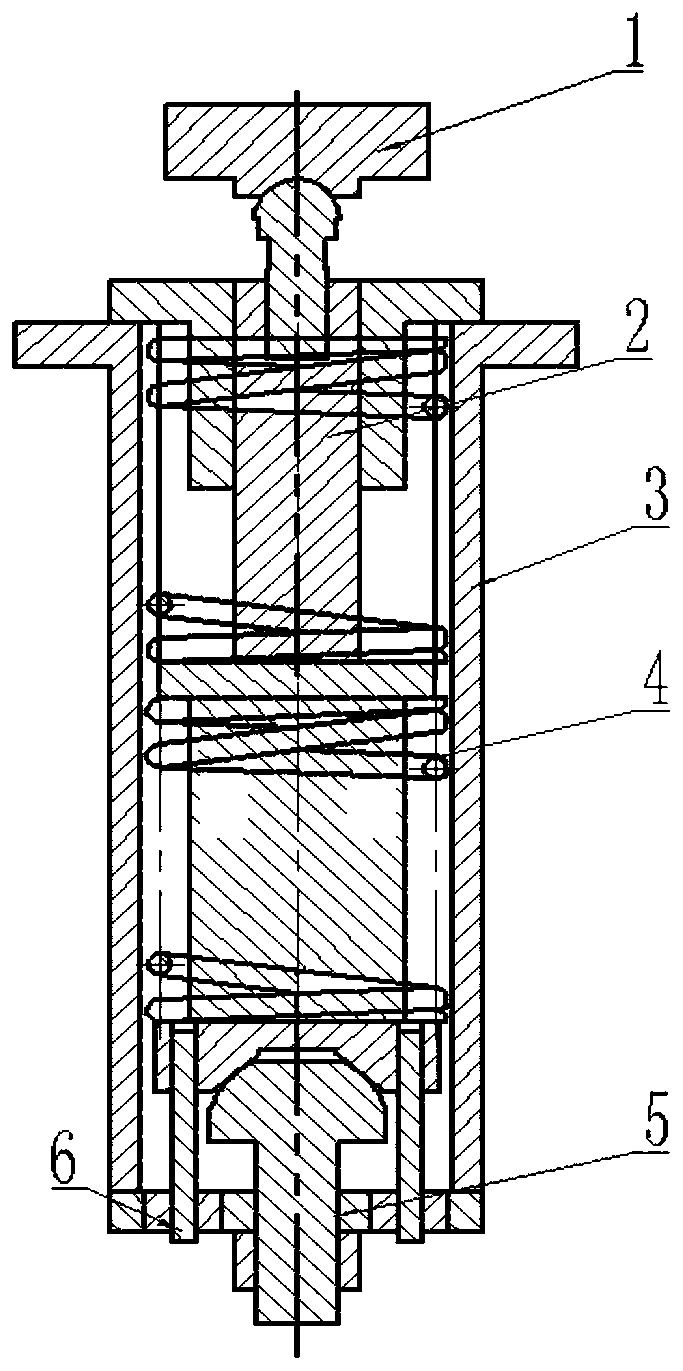

A retractable positioning device

A technology for telescopic positioning and positioning components, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of precision opto-mechanical instruments adjusting the position range, the compression preload can not effectively meet the design requirements, etc., to meet the adjustment and improve the installation. Adjusting accuracy and satisfying the effect of compression preload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

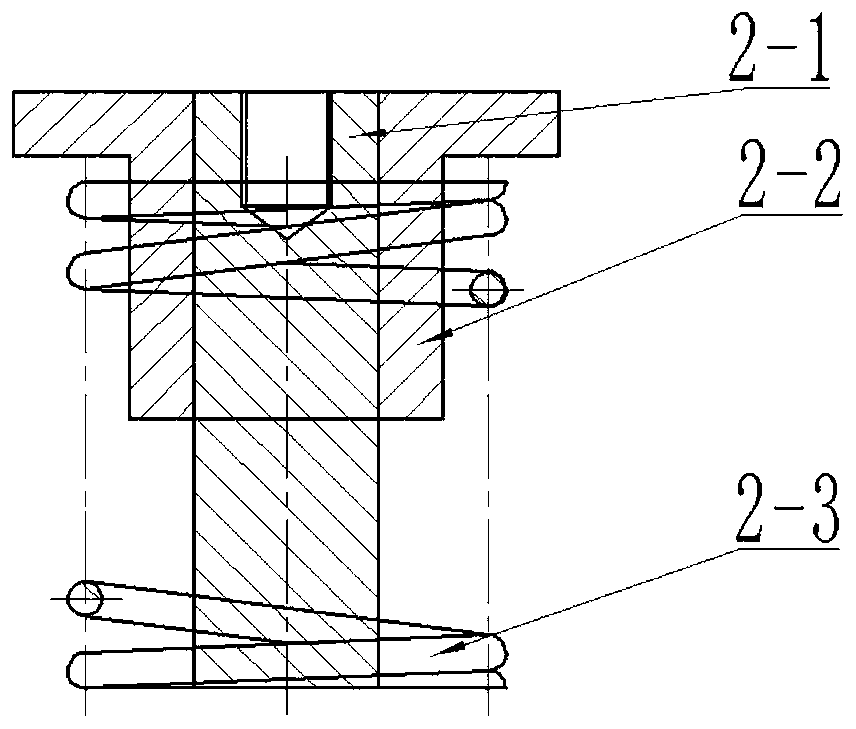

[0038] Further, see image 3 As shown, as a specific implementation of the retractable positioning device provided by the present invention, the linear bearing assembly 2 includes a linear bearing rod 2-1, a linear bearing seat 2-2, and a compression spring 2-3. A flange is set on the end face of the linear bearing seat 2-2 to be connected to the upper end face of the outer shell 3, and a through hole is set in the center of the linear bearing seat 2-2; the upper end of the compression spring 2-3 is connected to the inner side of the flange of the linear bearing seat 22 Connected, the lower end of the compression spring 2-3 is connected with the spring assembly 4. The top of the linear bearing rod 2-1 is provided with internal threads to connect with the ball support assembly 1, and the bottom of the linear bearing rod 2-1 passes through the through hole of the linear bearing seat 2-2 to connect with the spring assembly 4; The through hole of the linear bearing housing 2-2 reci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com