Heat gun

A hot air, air channel technology, used in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of measuring temperature, laborious manipulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

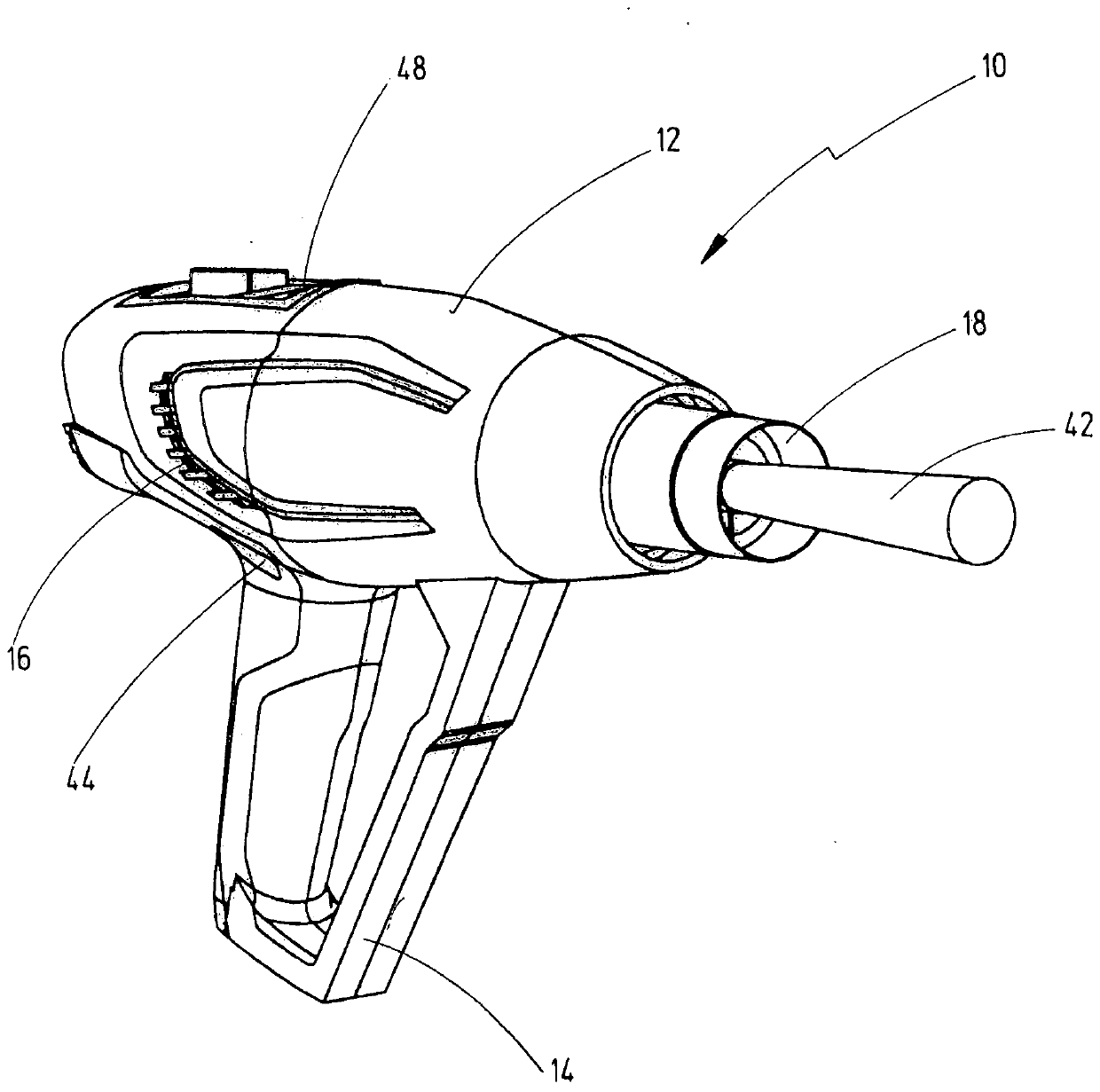

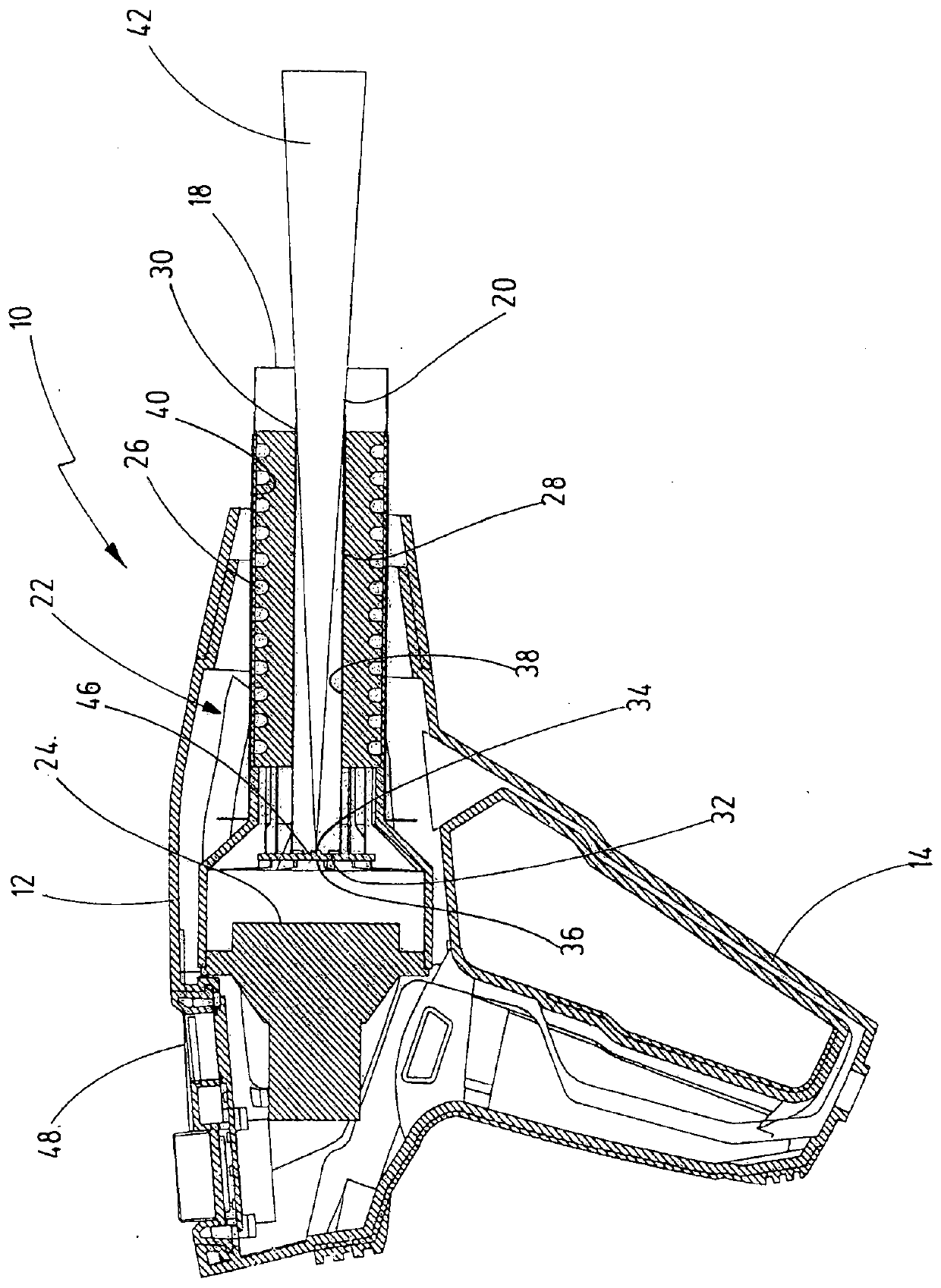

[0012] The hot air gun 10 shown in the drawing has a housing 12 with a handle 14 . The housing 12 also has an air inlet 16 in its rear region and an air outlet 18 on its front end, which is located partly at the figure 1 The right side visible in , is partially symmetrically located on the left side. An air duct 20 extends between the air inlet 16 and the air outlet 18, in which a hot air device 22 is arranged for sucking in ambient air via the air inlet 16, heating the ambient air and then distributing the hot air Blows through the air outlet 18 onto the workpiece to be heated. The hot air device 22 accordingly has a fan 24 and a heating unit 26 . The fan 24 is used to generate an air flow in the air channel 20 and the heating unit 26 is used to heat the air flowing past the heating unit.

[0013] Arranged in the air channel 20 is a measuring tube 28 whose front end 30 is open towards the air outlet 18 and which is arranged at a distance from the air outlet 18 so that it l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com