Truck scale weighing detection system and method and memory medium

A detection system and detection method technology, applied in the direction of measuring devices, detailed information of weighing equipment, instruments, etc., can solve the problems of inaccurate weighing, missed and overbalanced on-site strict supervision, etc., and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

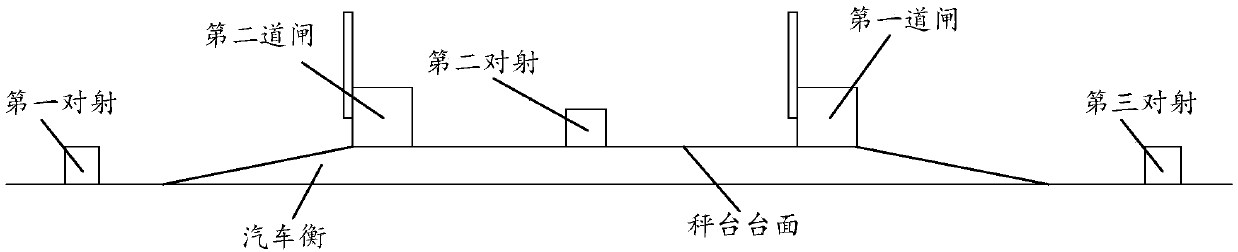

[0020] In order to solve the problem of inaccurate weighing caused by illegal operations in the prior art due to the strict supervision of the overweight site due to human error, the present invention provides a vehicle overweight detection system, method and storage medium. The following is combined with the attached Figures and Examples further describe the present invention in detail. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

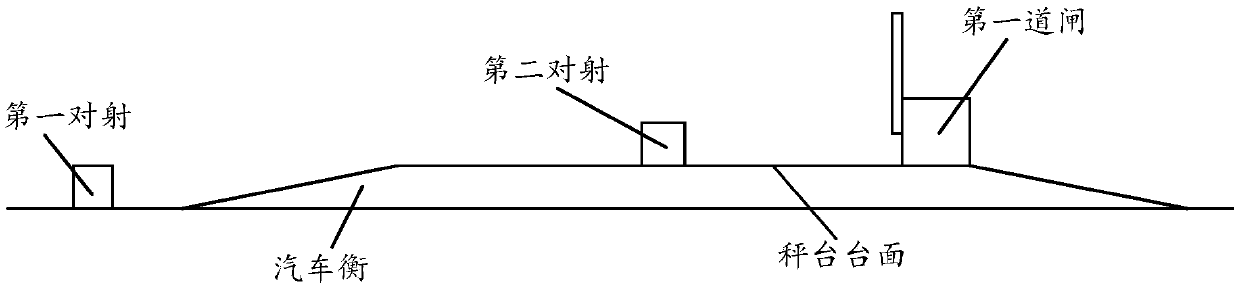

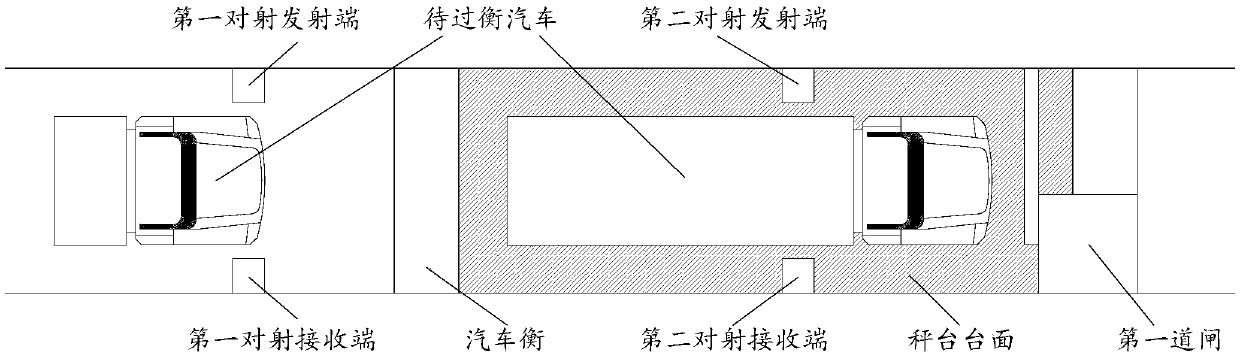

[0021] The first embodiment of the present invention provides a vehicle overweight detection system, the system schematic diagram is as follows figure 1 As shown, it mainly includes: the controller (the controller is often placed in the computer room or office, so it is figure 1 Not shown in), the truck scale, the first pair of shots, the second pair of shots and the first gate, wherein the truck scale, the first pair of shots, the second p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com