A riveting-free connection process of heterogeneous sheet materials

A technology for riveting connection and sheet metal, which is applied in the field of riveting-free connection of heterogeneous sheet materials, can solve problems such as difficulty in forming locks, and achieve the effects of improving production efficiency, realizing multi-layer connection, and being easy to automate mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail:

[0040] The rivetless connection process of heterogeneous sheets of the present invention includes the following processes:

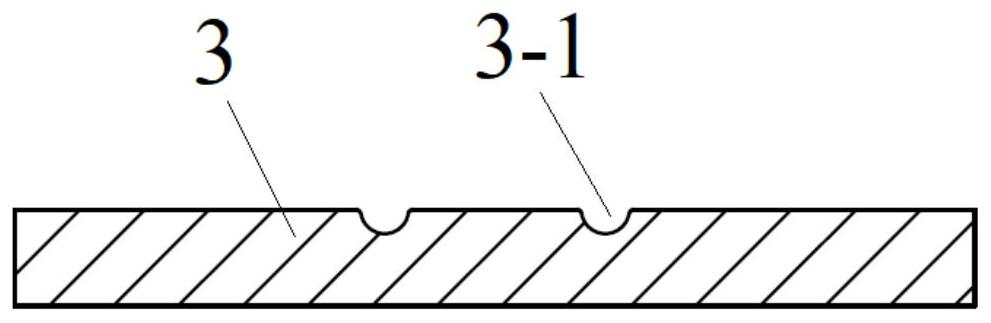

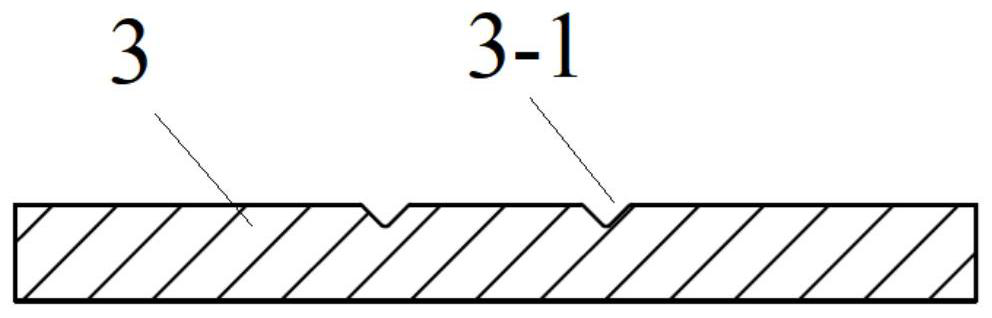

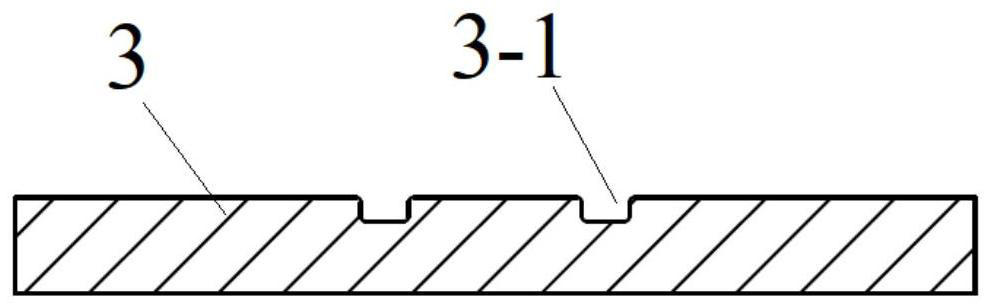

[0041] The first sheet material pretreatment stage: pretreat the first sheet material 3 and make a dangerous section on the surface of the first sheet material 3 . The shape of the dangerous section is diversified such as Figure 1 to Figure 5 As shown, among them, figure 1 , figure 2 and image 3 Respectively show the situation when the dangerous cross-section is an annular dangerous cross-section, and the cross-sectional shapes are arc-shaped, V-shaped and rectangular; Figure 4 It shows the situation that when the dangerous section is a combination of annular (section shape is arc-shaped) and columnar, the annular dangerous section is located at the outer edge of the bottom of the columnar dangerous section; Figure 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com