Cross-transport bullet-supplying magazine capable of supplementing ammunition any time

A technology for ammunition supply and ammunition, which is applied in ammunition supply, weapon accessories, offensive equipment, etc. It can solve the problems of ammunition waste, lack of freedom in changing ammunition, inconvenience in combat, etc., and achieve the effect of reliable work, reasonable distribution of parts, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the drawings.

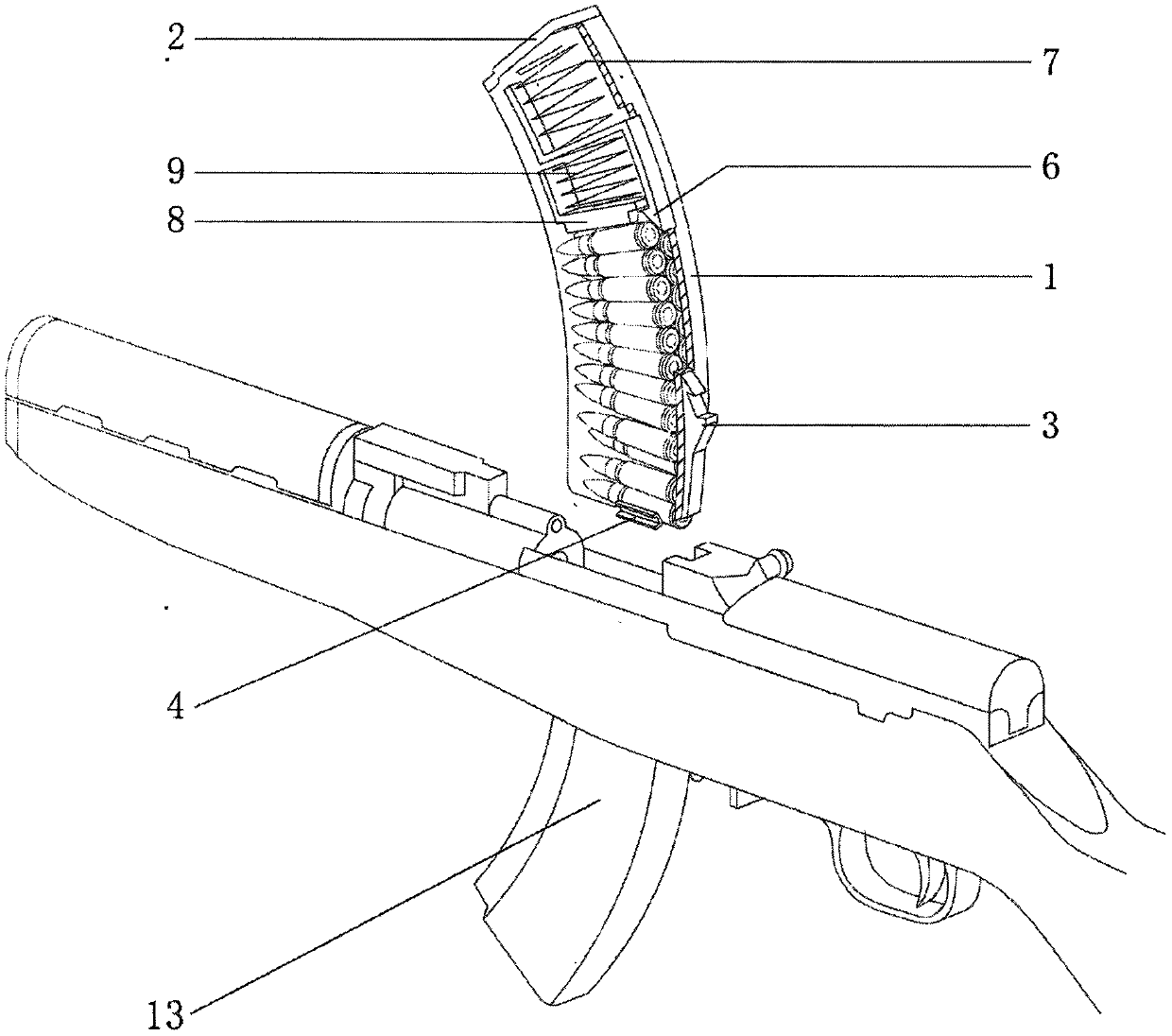

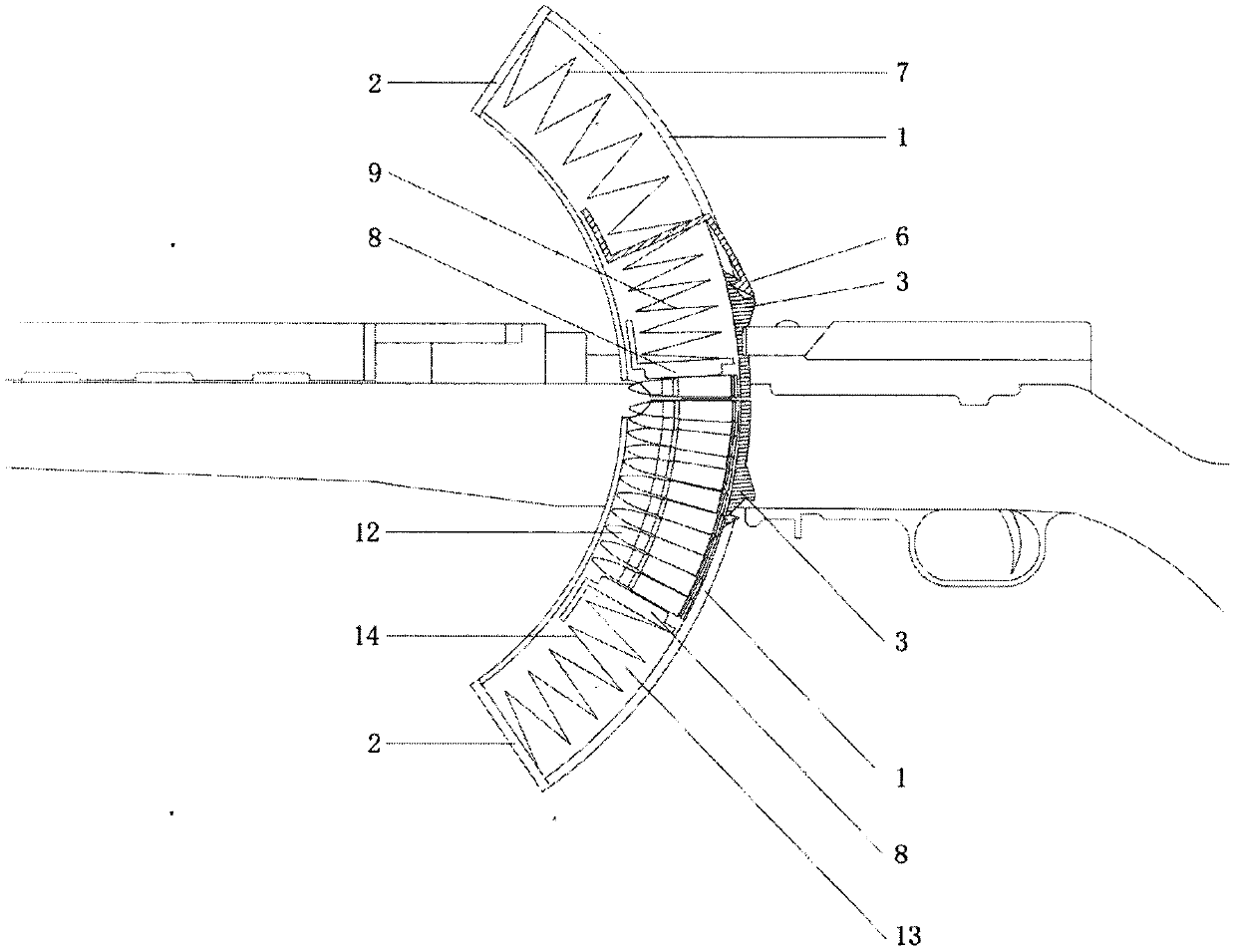

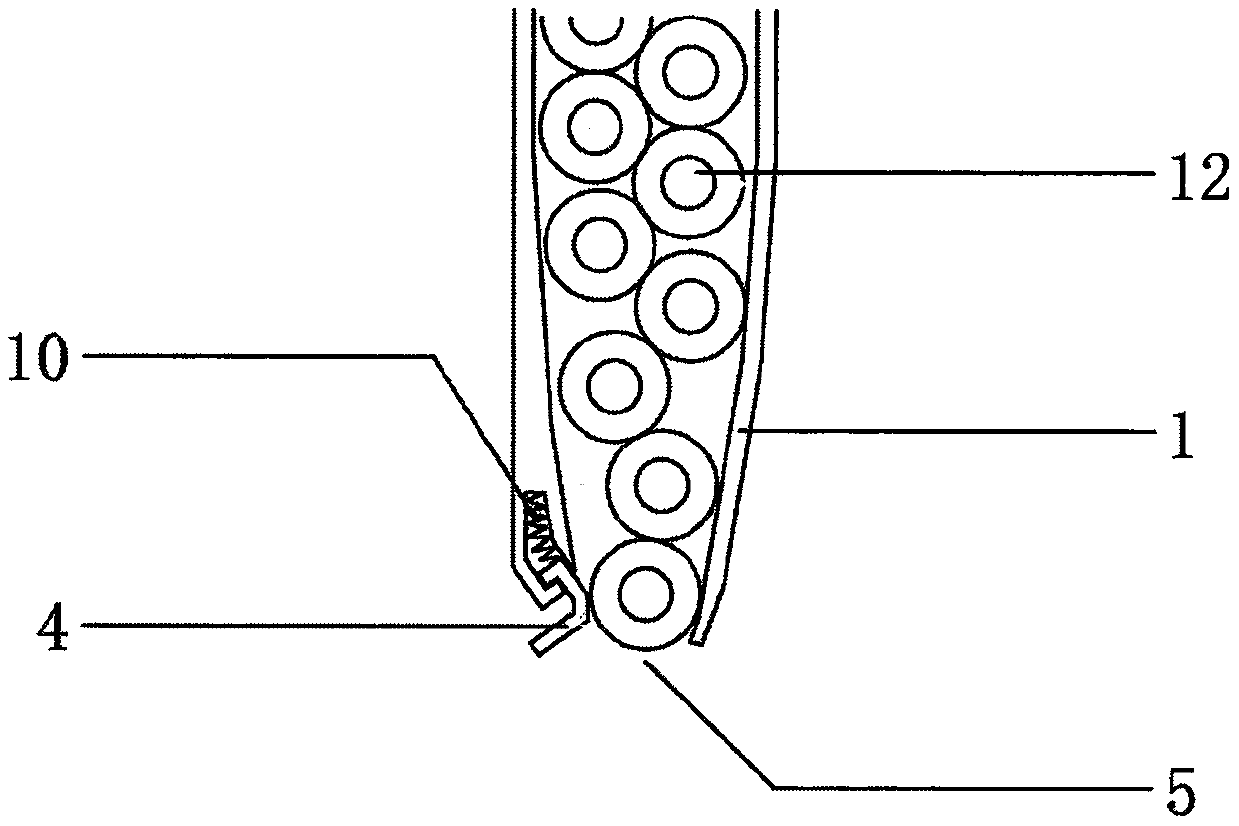

[0022] Combine image 3 , Figure 5 , Can realize the replenishment of ammunition at any time, the transfer and supply of the magazine, the transfer and supply of the magazine includes the magazine shell (1), the bottom plate (2), the upper supply spring (9), the support plate (8) ), the lower supply spring (7), the deduction valve mechanism and the limit mechanism. The bottom plate (2) is installed at the bottom end of the magazine shell (1) for blocking the delivery and supply of the ammunition The bottom end of the box is open, the limit mechanism includes a limit spring sheet (6) and a limit latch (3), and the buckle shutter mechanism includes a movable buckle spring tooth (4) and a buckle spring tooth spring (10) The movable buckle spring teeth (4) are located on the side of the upper mouth (5) of the magazine shell. The two ends of the buckle spring tooth spring (10) are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com