A kind of anti-cracking mortar for repairing pipeline wall groove

A wall groove and anti-cracking technology, applied in the field of building mortar, can solve the problems of hollowing, cracking, multiple cracks and affecting the appearance of the fine decoration surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

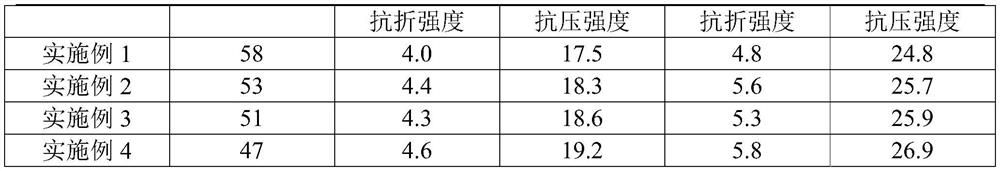

Embodiment 1

[0022] An anti-crack mortar for repairing pipeline wall grooves is prepared from the following raw materials in parts by weight: 1.0 parts by weight of Portland cement, 0.225 parts by weight of desulfurized gypsum powder, 4.2 parts by weight of medium sand, 1.0 parts by weight of water, 10-20 mm long 0.18 parts by weight of lignin fiber, in addition, the following additives are added in percentage by weight, water retaining agent 0.16wt%, polyacrylic resin rubber powder 0.16wt%; wherein, the particle size of the medium sand is 0.25 ~ 0.40mm, the median particle size D 50 0.30mm, the fineness modulus is 2.7-2.3, and the water-retaining agent is a commercially available copolymerized polymer water-retaining agent.

Embodiment 2

[0024] An anti-cracking mortar for repairing pipeline wall grooves, which is prepared from the following raw materials: 0.9 parts by weight of Portland cement, 0.2 parts by weight of desulfurized gypsum powder, 5.6 parts by weight of medium sand, 0.8 parts by weight of water, and 10-20 mm lignin 0.16 parts by weight of fiber, in addition, the following additives are added in percentage by weight, water retaining agent 0.14wt%, polyvinyl alcohol resin powder 0.14wt%; wherein, the particle size of the medium sand is 0.25mm, and the median particle size is D 50 It is 0.30mm, and the fineness modulus is 2.7.

[0025] In addition, the water-retaining agent used is prepared by the following method. The palygorskite is crushed and then mixed with a 1.5mol / L potassium acetate solution that is 1 times the weight of the palygorskite, ball milled at a speed of 1400rpm for 2 hours, and then left to age for 12 hours Prepare the palygorskite mixed slurry, dry the palygorskite mixed slurry a...

Embodiment 3

[0027] An anti-cracking mortar for repairing pipeline wall grooves, which is prepared from the following raw materials: 1.5 parts by weight of Portland cement, 0.6 parts by weight of desulfurized gypsum powder, 6.4 parts by weight of medium sand, 1.2 parts by weight of water, and 10-20 mm polypropylene 0.24 parts by weight of fiber, in addition, the following additives are added in percentage by weight, water retaining agent 0.20wt%, polyacrylic resin rubber powder 0.20wt%; wherein, the particle size of the medium sand is 0.50mm, and the median particle size is D 50 It is 0.35mm, and the fineness modulus is 2.3.

[0028]In addition, the water-retaining agent used is prepared by the following method, crushing palygorskite and then mixing it with 1.5mol / L potassium acetate solution 2.0 times the weight of palygorskite, ball milling at a speed of 1900rpm for 2.5 hours, and then standing and aging for 24 hours Prepare the palygorskite mixed slurry, dry the palygorskite mixed slurr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com