Anti-cracking mortar for repairing decoration pipeline wall slots

A wall trough and anti-cracking technology, applied in the field of building mortar, can solve the problems of uneven shrinkage, hollow cracking, hollow cracking and failure of fine decoration surface layer, etc., to improve penetration and occlusion, enhance repair strength, and shorten hydration. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

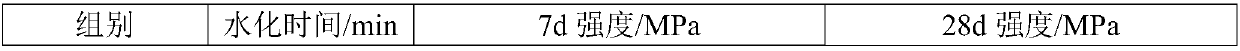

Examples

Embodiment 1

[0022] An anti-crack mortar for repairing pipeline wall grooves is prepared from the following raw materials in parts by weight: 1.0 parts by weight of Portland cement, 0.225 parts by weight of desulfurized gypsum powder, 4.2 parts by weight of medium sand, 1.0 parts by weight of water, 10-20 mm long 0.18 parts by weight of lignin fiber, in addition, the following additives are added in percentage by weight, water retaining agent 0.16wt%, polyacrylic resin rubber powder 0.16wt%; wherein, the particle size of the medium sand is 0.25 ~ 0.40mm, the median particle size D 50 0.30mm, the fineness modulus is 2.7-2.3, and the water-retaining agent is a commercially available copolymerized polymer water-retaining agent.

Embodiment 2

[0024] An anti-cracking mortar for repairing pipeline wall grooves, which is prepared from the following raw materials: 0.9 parts by weight of Portland cement, 0.2 parts by weight of desulfurized gypsum powder, 5.6 parts by weight of medium sand, 0.8 parts by weight of water, and 10-20 mm lignin 0.16 parts by weight of fiber, in addition, the following additives are added in percentage by weight, water retaining agent 0.14wt%, polyvinyl alcohol resin powder 0.14wt%; wherein, the particle size of the medium sand is 0.25mm, and the median particle size is D 50 It is 0.30mm, and the fineness modulus is 2.7.

[0025] In addition, the water-retaining agent used is prepared by the following method. The palygorskite is crushed and then mixed with a 1.5mol / L potassium acetate solution that is 1 times the weight of the palygorskite, ball milled at a speed of 1400rpm for 2 hours, and then left to age for 12 hours Prepare the palygorskite mixed slurry, dry the palygorskite mixed slurry a...

Embodiment 3

[0027] An anti-cracking mortar for repairing pipeline wall grooves, which is prepared from the following raw materials: 1.5 parts by weight of Portland cement, 0.6 parts by weight of desulfurized gypsum powder, 6.4 parts by weight of medium sand, 1.2 parts by weight of water, and 10-20 mm polypropylene 0.24 parts by weight of fiber, in addition, the following additives are added in percentage by weight, water retaining agent 0.20wt%, polyacrylic resin rubber powder 0.20wt%; wherein, the particle size of the medium sand is 0.50mm, and the median particle size is D 50 It is 0.35mm, and the fineness modulus is 2.3.

[0028]In addition, the water-retaining agent used is prepared by the following method, crushing palygorskite and then mixing it with 1.5mol / L potassium acetate solution 2.0 times the weight of palygorskite, ball milling at a speed of 1900rpm for 2.5 hours, and then standing and aging for 24 hours Prepare the palygorskite mixed slurry, dry the palygorskite mixed slurr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com