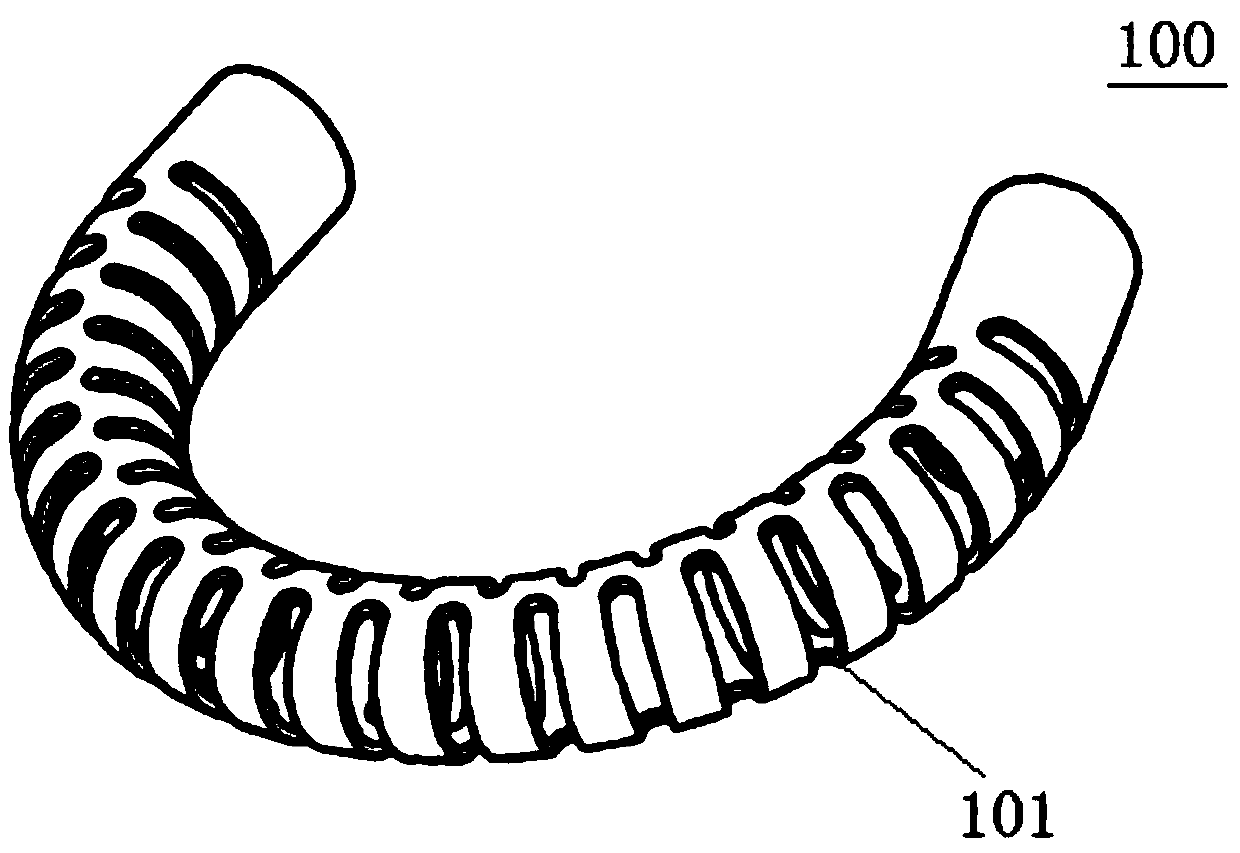

Flexible joint

A technology of flexible joints and curved segments, applied in surgical robots and other directions, can solve problems such as unpredictable deformation effects, uncertain deformation patterns, and uneven materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

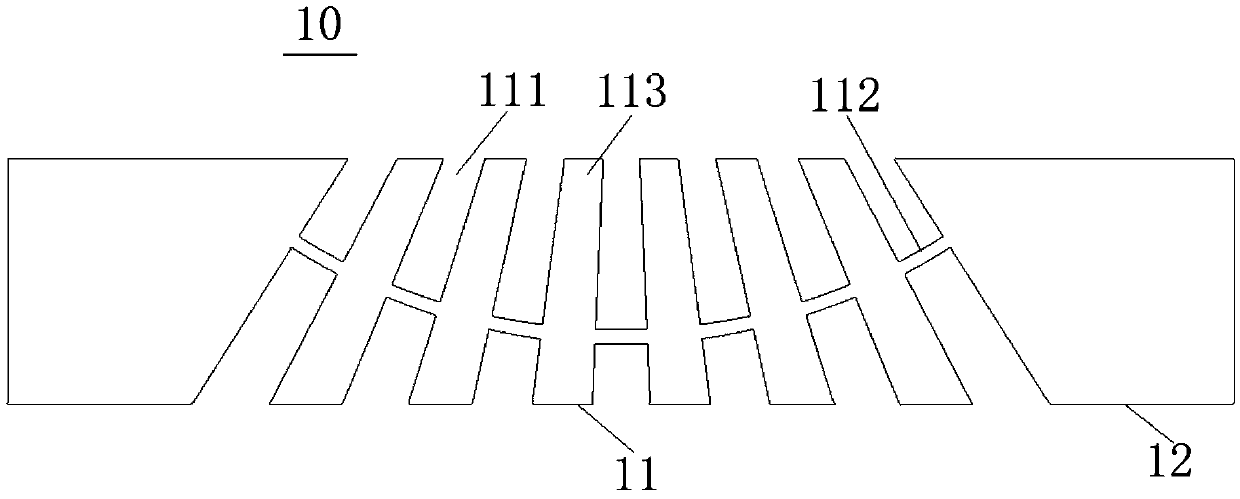

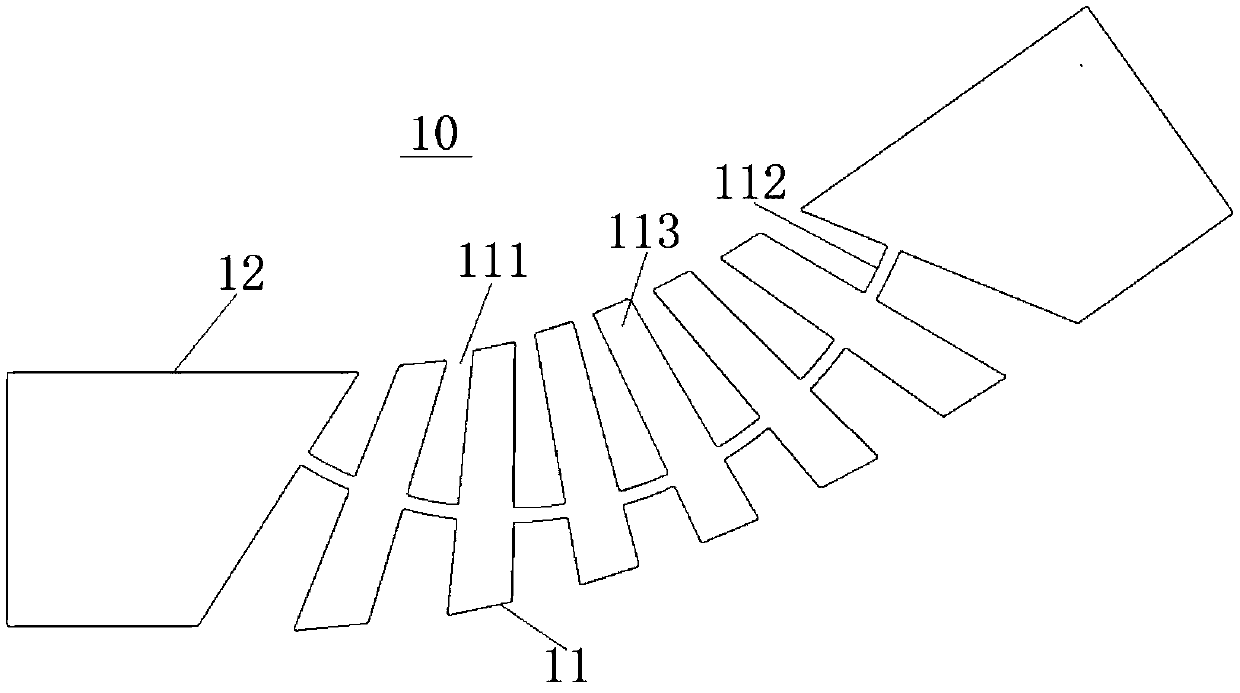

[0056] Please refer to Figure 2 to Figure 3, in this embodiment, the flexible joint unit 10 can have seven bending sections, each of which includes a radial notch 111 and a connecting rib 112, and an annular band 113 is formed between two adjacent bending sections so as to pass through the ring The connecting ribs 112 of two adjacent bending sections are connected together by the endless belt 113 . The annular band 113 is formed by a part of the remaining side wall, which surrounds the circumferential direction of the curved section 11, and correspondingly, the connecting rib 112 is formed by another part of the remaining side wall, which is formed by the other part of the remaining side wall on the curved section 11. connection between the two ends.

[0057] Each of the annular belts 113 of the flexible joint unit 10 is grouped to form a radially inner annular belt system and a radially outer annular belt system. Each of the radially inner annular belt system and the radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com