Intelligent system controlling flexible clamping force in thermal width adjustment for crystallizer, and use method thereof

A technology of crystallization control and intelligent system, which is applied in the field of metallurgical continuous casting equipment, can solve the problems of small soft clamping force, time-consuming, labor-intensive, time-consuming and labor-intensive problems, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

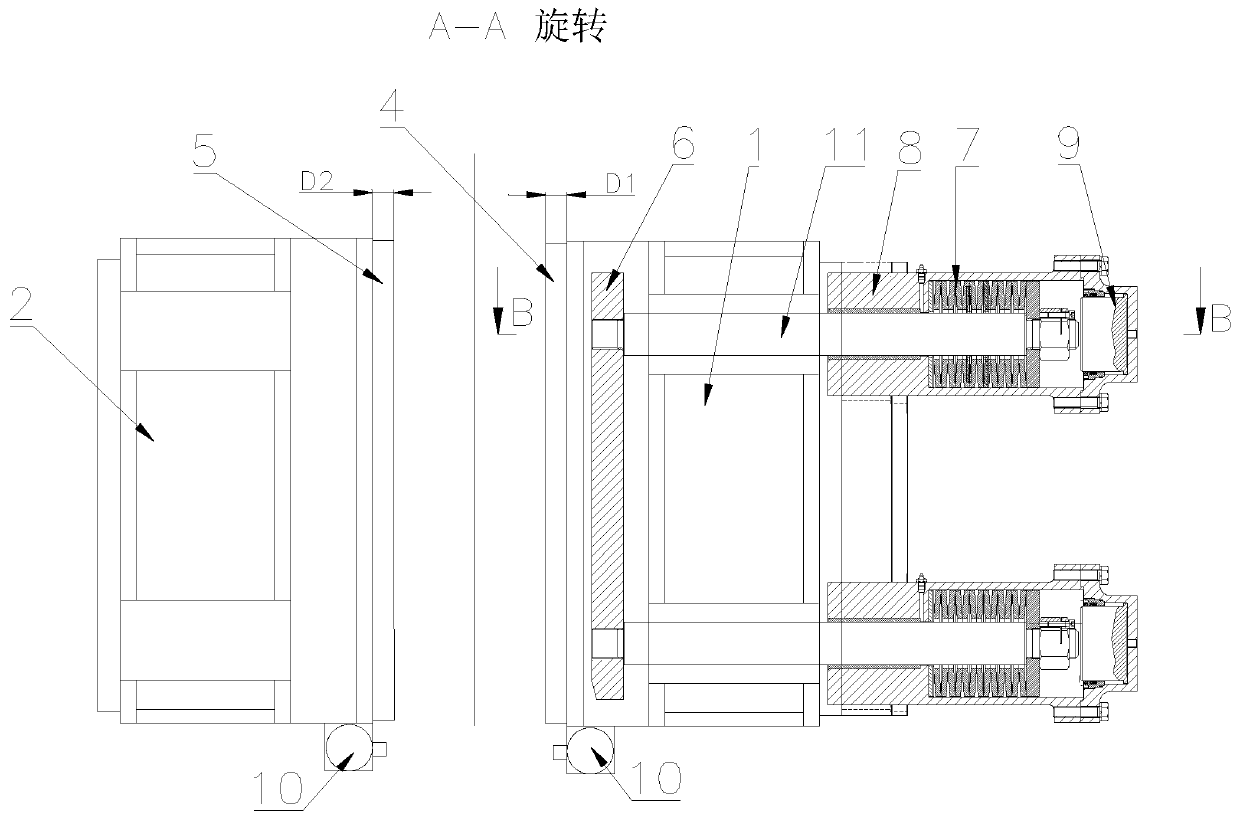

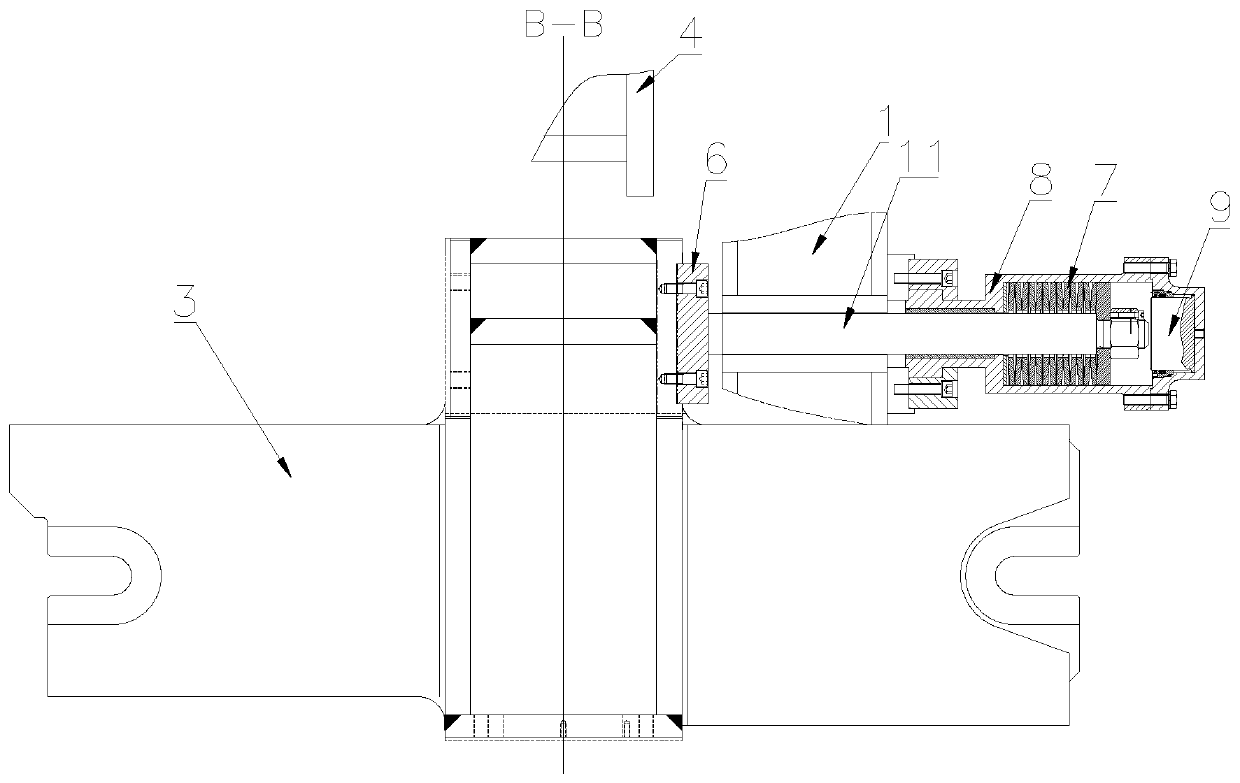

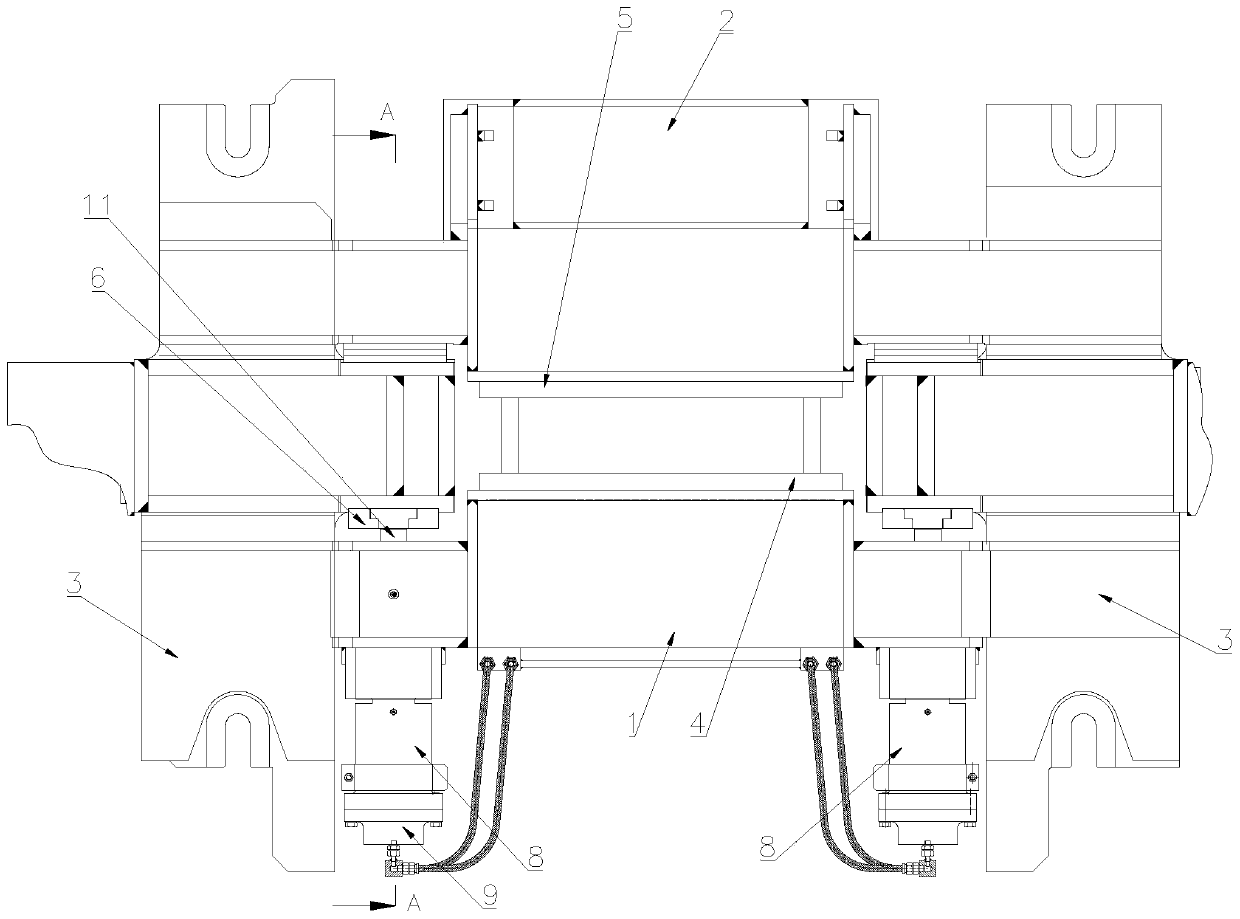

[0071] refer to figure 1 , figure 2 , image 3 and Figure 4 , an intelligent system to control the thermally adjustable soft clamping force of the mold, including

[0072] Mold side frame 3;

[0073] Side frame fixing plate 6, side frame fixing plate 6 is connected on the crystallizer side frame 3;

[0074] Mold inner arc frame 1;

[0075] The mold outer arc frame 2, the mold inner arc frame 1 and the mold outer arc frame 2 are arranged oppositely, and the mold side frames 3 are connected to both sides of the mold inner arc frame 1 and the mold outer arc frame 2;

[0076] Crystallizer clamping and releasing device, the crystallizer clamping and releasing device is connected on the side frame fixing plate 6;

[0077] The mold inner arc copper plate 4, the mold inner arc copper plate 4 is arranged on the mold inner arc frame 1;

[0078] The mold outer arc copper plate 5, the mold outer arc copper plate 5 is arranged on the mold outer arc frame 2;

[0079] An infrared d...

Embodiment 2

[0085] refer to figure 1 and figure 2 , compared with Embodiment 1, the difference of this embodiment is that: the crystallizer clamping and releasing device includes

[0086] release cylinder 9;

[0087] The disc spring sleeve 8 is detachably connected to one end of the cylinder body of the release cylinder 9, and one side of the disc spring sleeve 8 is also fixedly connected to the mold inner arc frame 1;

[0088] The disc spring 7 is arranged in the disc spring sleeve 8;

[0089] A guide rod 11, one end of the guide rod 11 is detachably connected to the disc spring 7, and the other end of the guide rod 11 is connected to the side frame fixing plate 6;

[0090] The other end of the release cylinder 9 is connected with the crystallizer release cylinder valve table through a pipeline.

[0091] In actual use: when the hydraulic pressure of the release cylinder 9 changes, the release cylinder 9 will release the pressure. Since the guide rod 11 is directly connected to the m...

Embodiment 3

[0093] Compared with Embodiment 2, the difference of this embodiment is that there are four crystallizer clamping and releasing devices, and the four mold clamping and releasing devices are all connected to the mold inner arc frame 1 , and two crystallizer inner arc frame 1 are installed on the upper side, and two crystallizer clamping and releasing devices are installed on the lower side.

[0094] In actual use: Install two mold clamping and releasing devices on the upper side of the mold inner arc frame 1, and two mold clamping and releasing devices on the lower side, and at the same time drive the mold inner arc copper plate 4 away from the mold outer arc. The trend of copper plate 5 achieves the fine-tuning of the thermal adjustment process, and the fine-tuning effect is the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com