Laser level meter support

A laser level and leveling technology, which is applied in the direction of instruments, measuring instruments, active optical measuring devices, etc., can solve problems such as angle adjustment, and achieve the effect of large market application and promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in detail below in conjunction with the accompanying drawings.

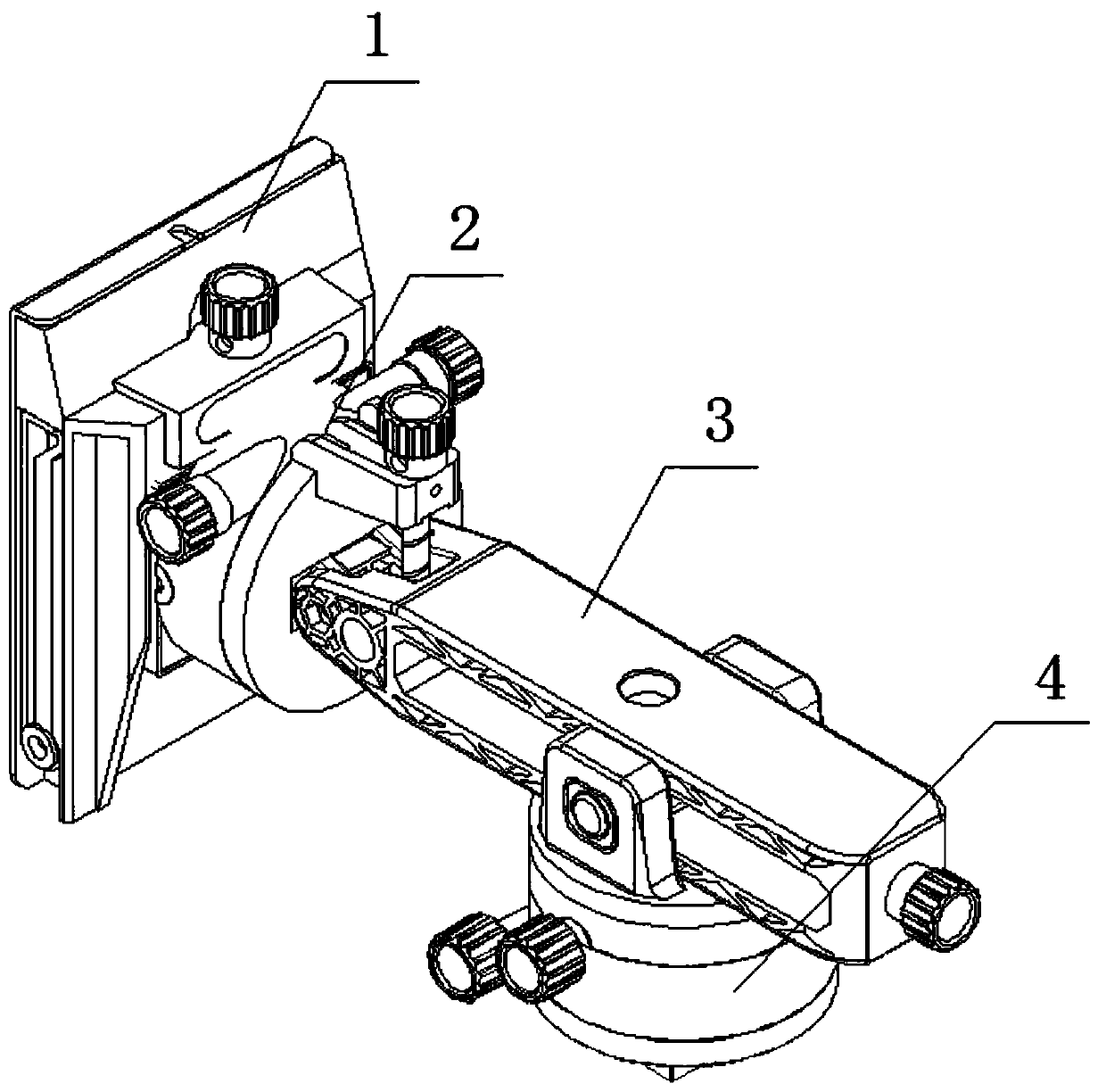

[0061] A laser level bracket, comprising a base 1, a vertical rotation device 2, a height adjustment bracket 3, and a laser level fixing frame 4;

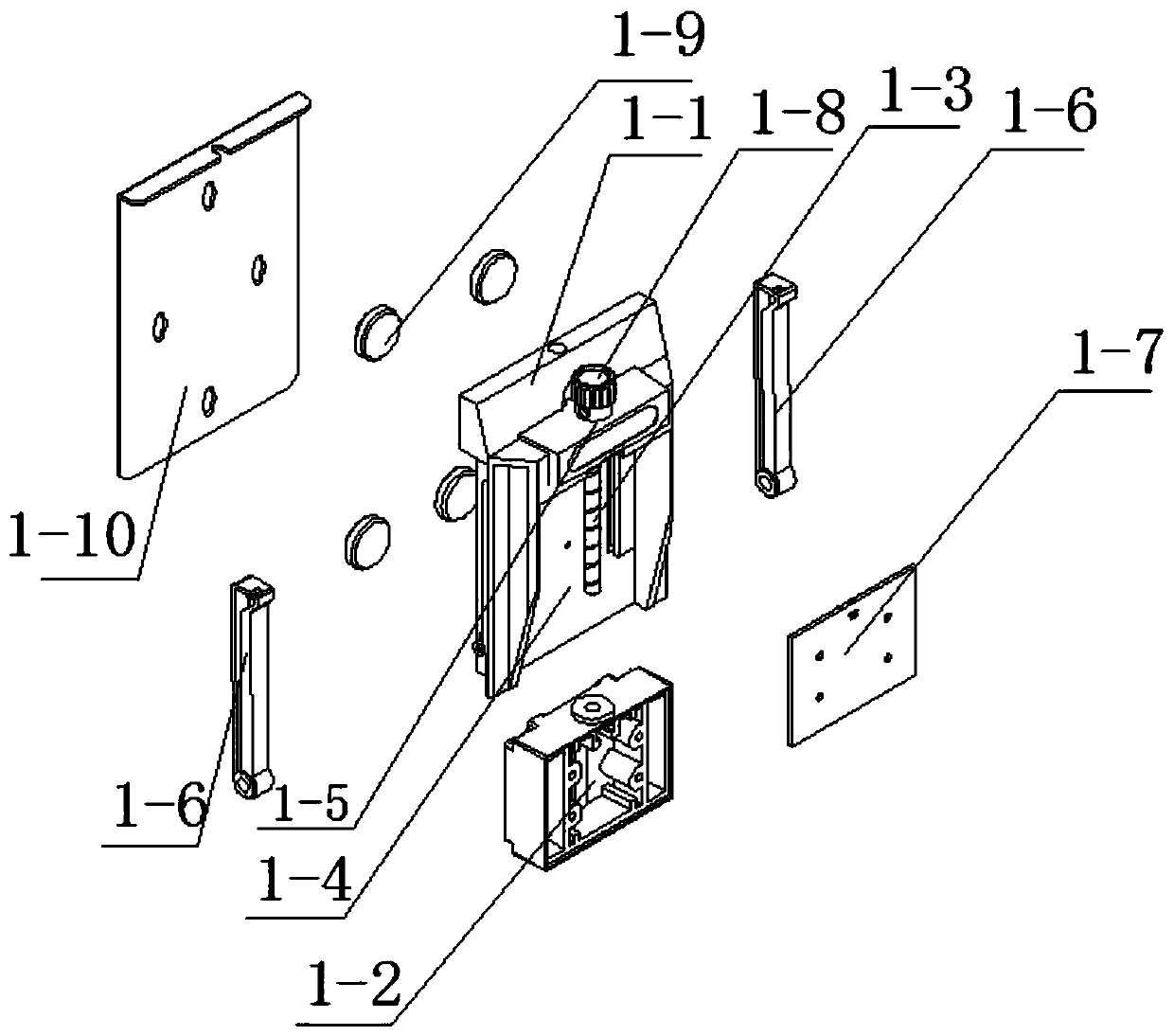

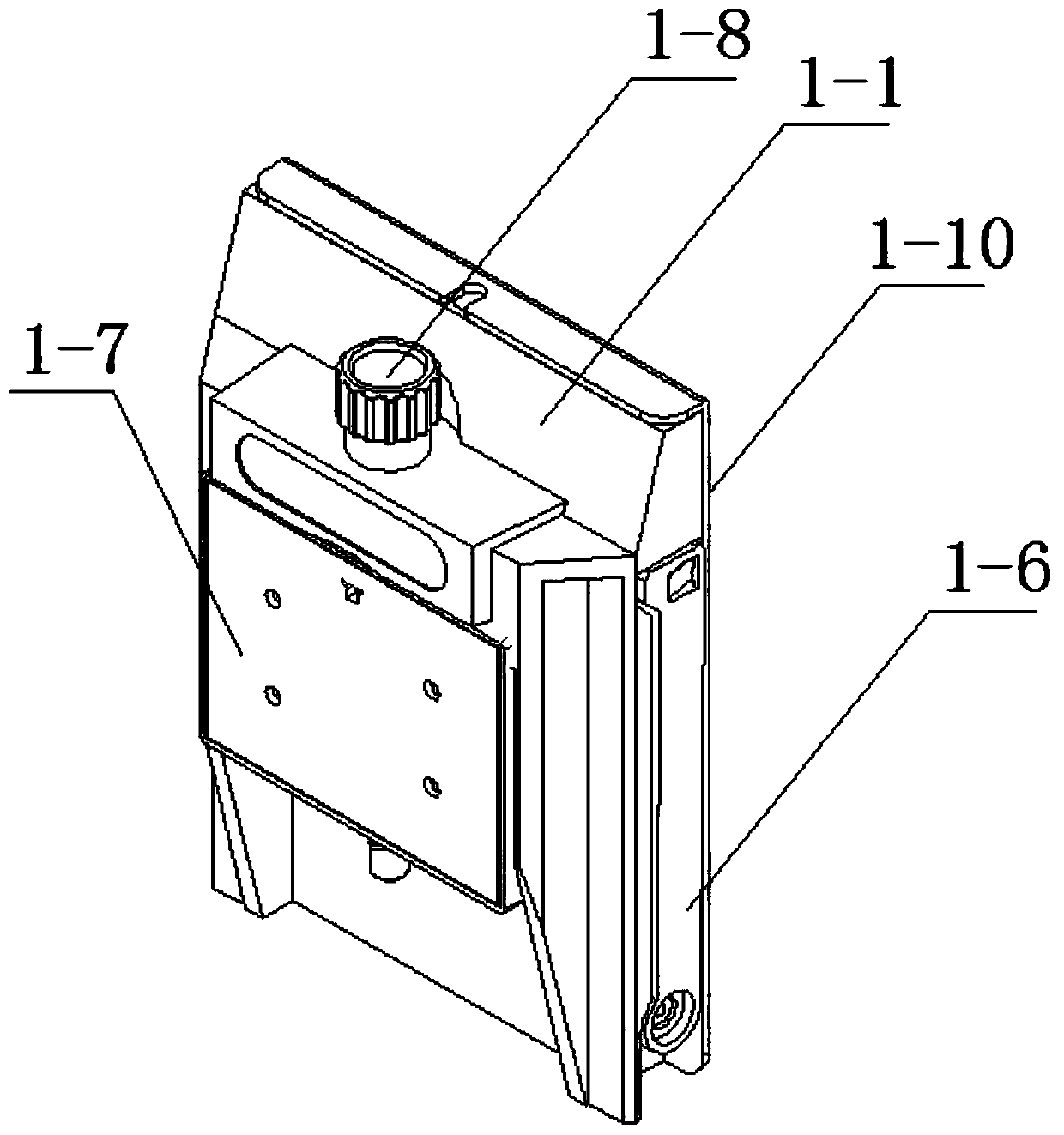

[0062] The base 1 includes a strong magnetic wall mount 1-1, a moving slider 1-2, a slider screw 1-3, and the strong magnetic wall mount 1-1 is provided with several magnets 1-9; The front of wall base 1-1 is provided with chute 1-4, and mobile slider 1-2 is placed in chute 1-4; The block screw 1-3 passes through the screw hole 1-5 and is placed in the chute 1-4; the moving slider 1-2 is provided with a slider threaded hole, and the slider screw 1-3 is provided with Matching external thread of the screw, one end of the slider screw 1-3 in the chute 1-4 is screwed into the slider threaded hole in the moving slider 1-2;

[0063] The vertical rotating device is fixedly connected to the moving slider 1-2; the screw rod 1-3 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap