A kind of three-dimensional embroidery manufacturing method

A technology of three-dimensional embroidery and manufacturing method, which is applied in the field of embroidery, and can solve the problems of poor touch and easy hook damage of the bottom line on the back

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

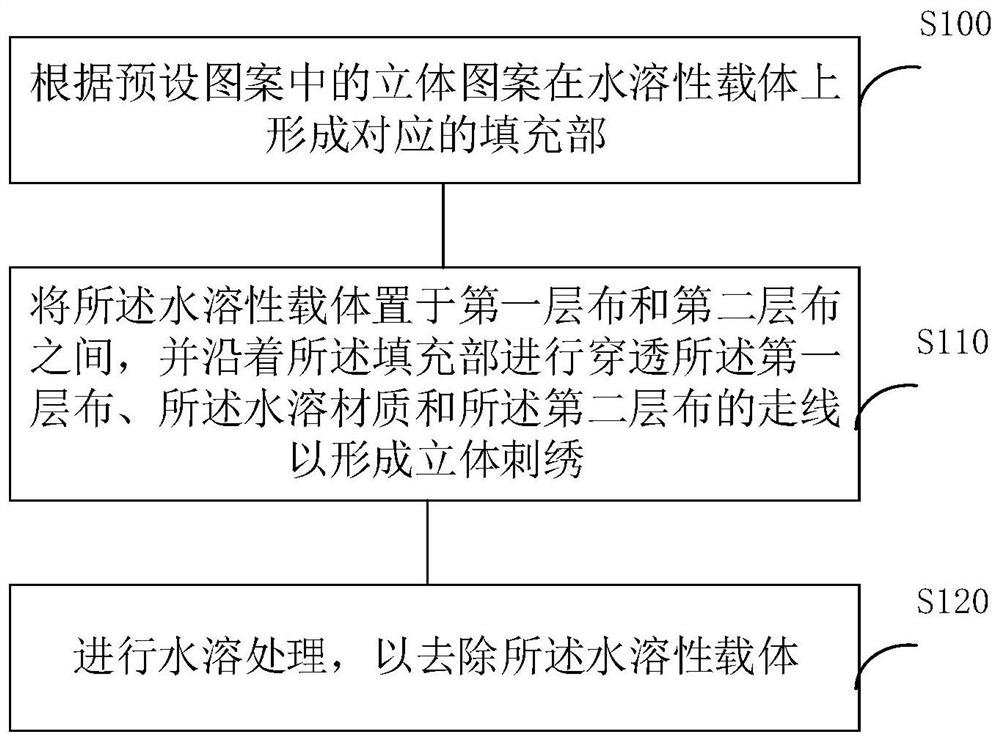

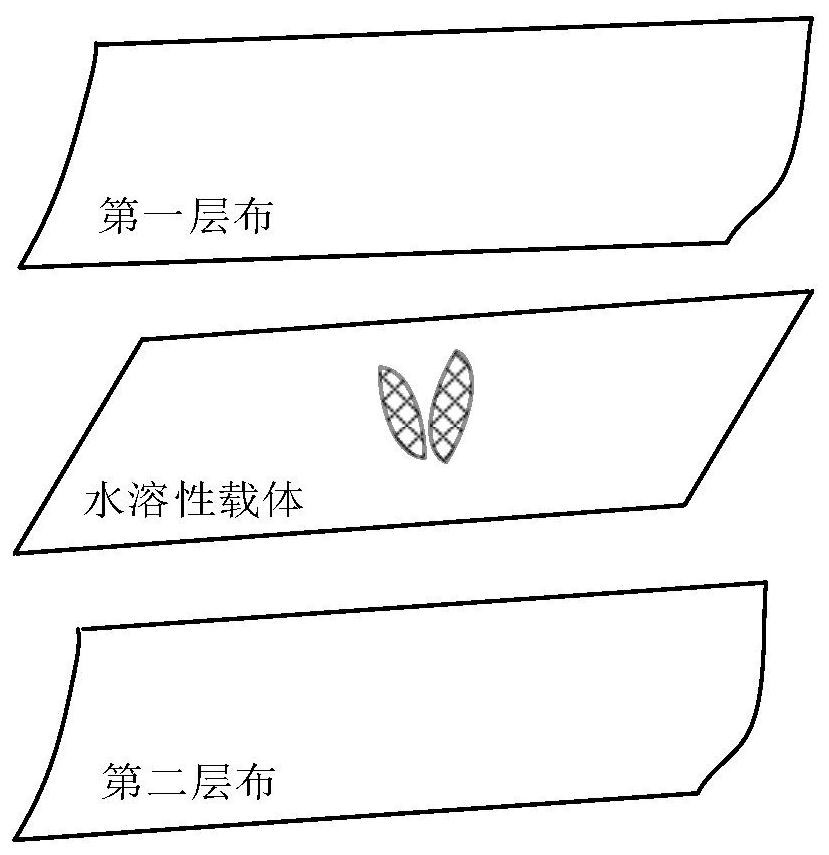

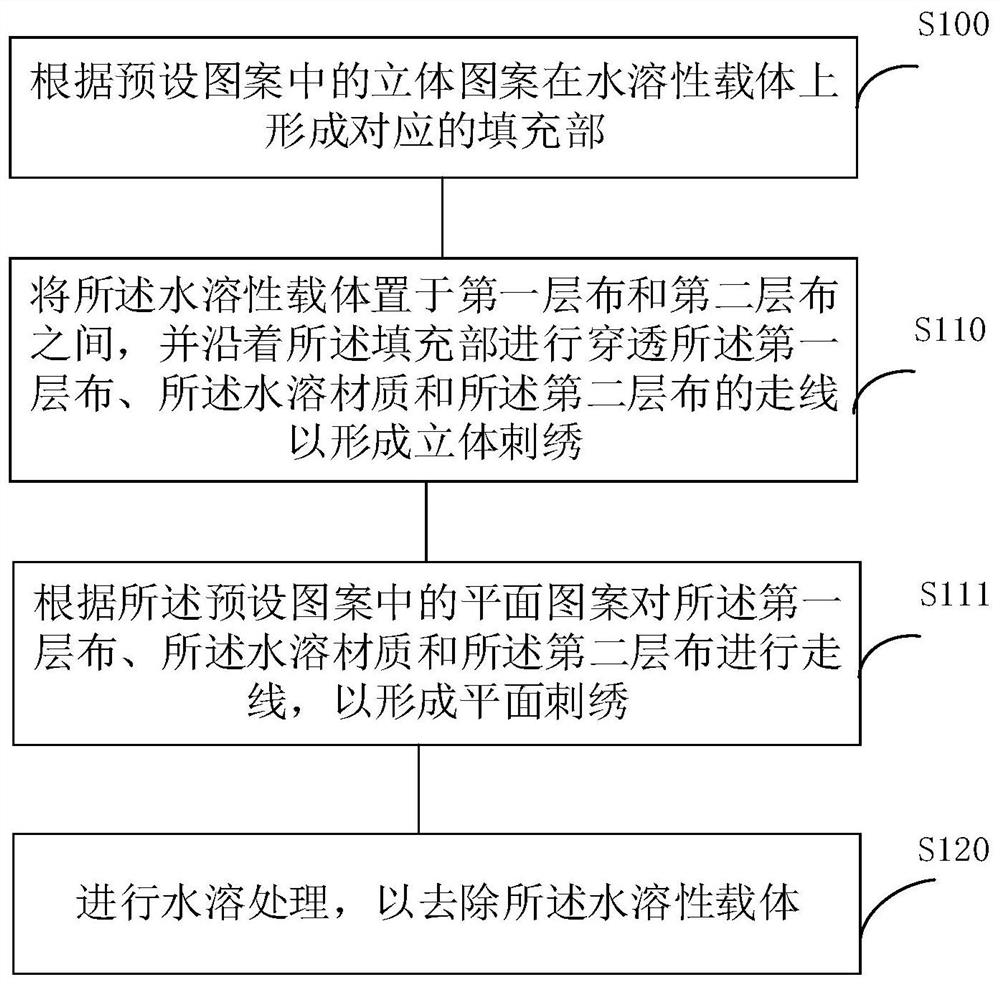

[0036] Please refer to figure 1 , This embodiment proposes a three-dimensional embroidery manufacturing method, which can be used in the three-dimensional embroidery production process, so as to obtain embroidery products with three-dimensional aesthetic effects.

[0037] Wherein, the preset pattern mentioned in this embodiment is also called a tape pattern or an embroidery pattern, which mainly plays a role of decoration and the like on the textile through embroidery. In order to make some patterns in the embroidery pattern present a three-dimensional effect, the inventor proposed a method different from the traditional embroidery method to solve the problem that the bottom line on the back of the existing traditional embroidery method has a bad touch or needs to be done manually every time. Three-dimensional area filling and other issues.

[0038] like figure 1 As shown, the three-dimensional embroidery manufacturing method mainly includes:

[0039] Step S100, forming a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com