Method and system for acquiring radial clearance of bearing and method and system for adjusting radial clearance of bearing

A radial clearance and acquisition method technology, applied in the field of bearing equipment, can solve the problem of inaccurate radial clearance and achieve the effect of accurate radial clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

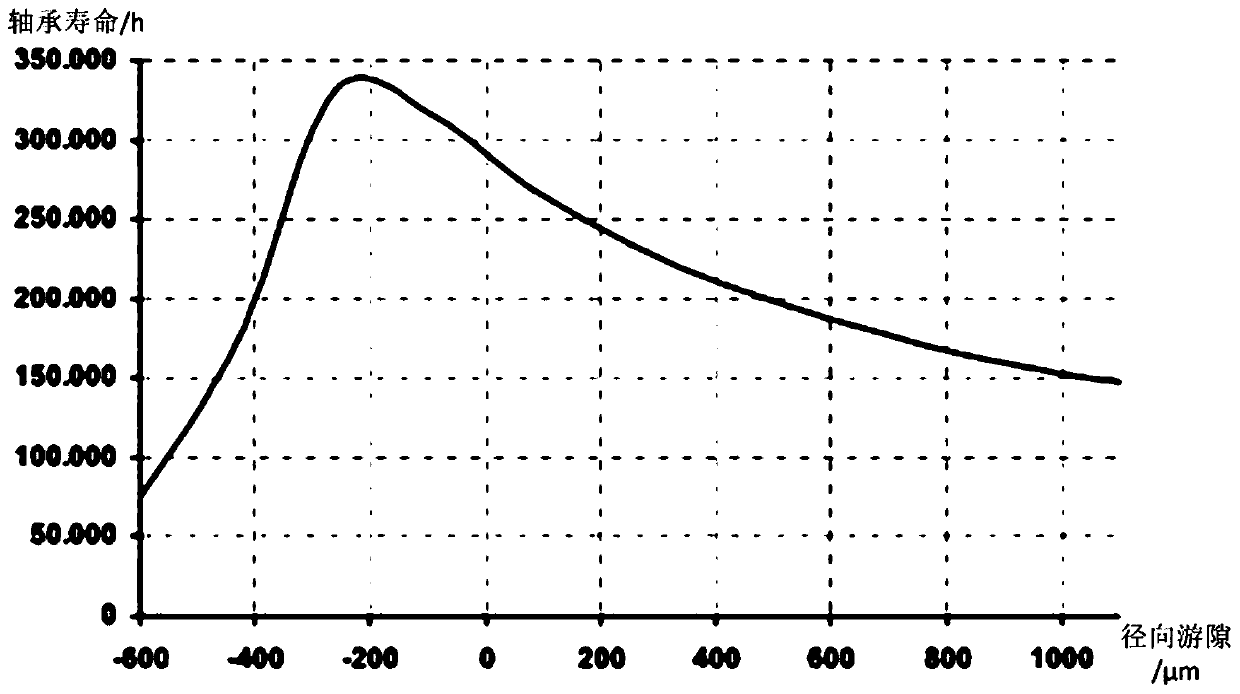

[0072] It can be seen from the background art that the working clearance of the bearing has a great influence on the working life of the bearing.

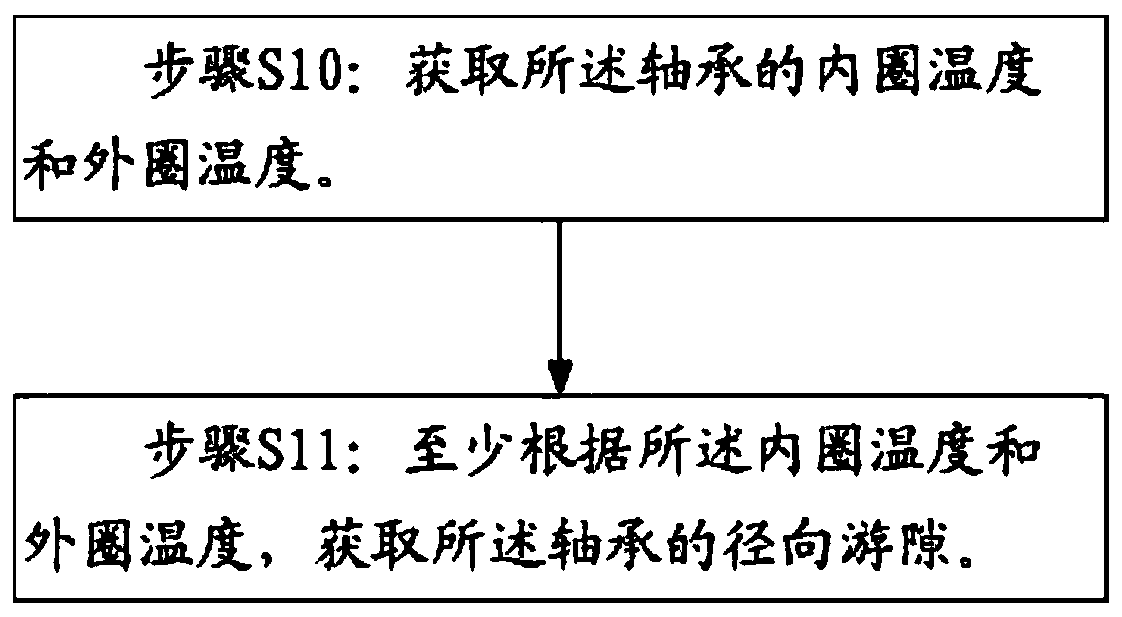

[0073] Please refer to figure 1 , figure 1 It is a schematic diagram of bearing life changing with radial clearance under working conditions.

[0074] according to figure 1 , under certain working conditions, as the radial clearance changes in the working state of the bearing, the life of the bearing will have a maximum value. The optimal working clearance can be obtained through calculation of the mechanical analysis model of the bearing, or through actual experiments.

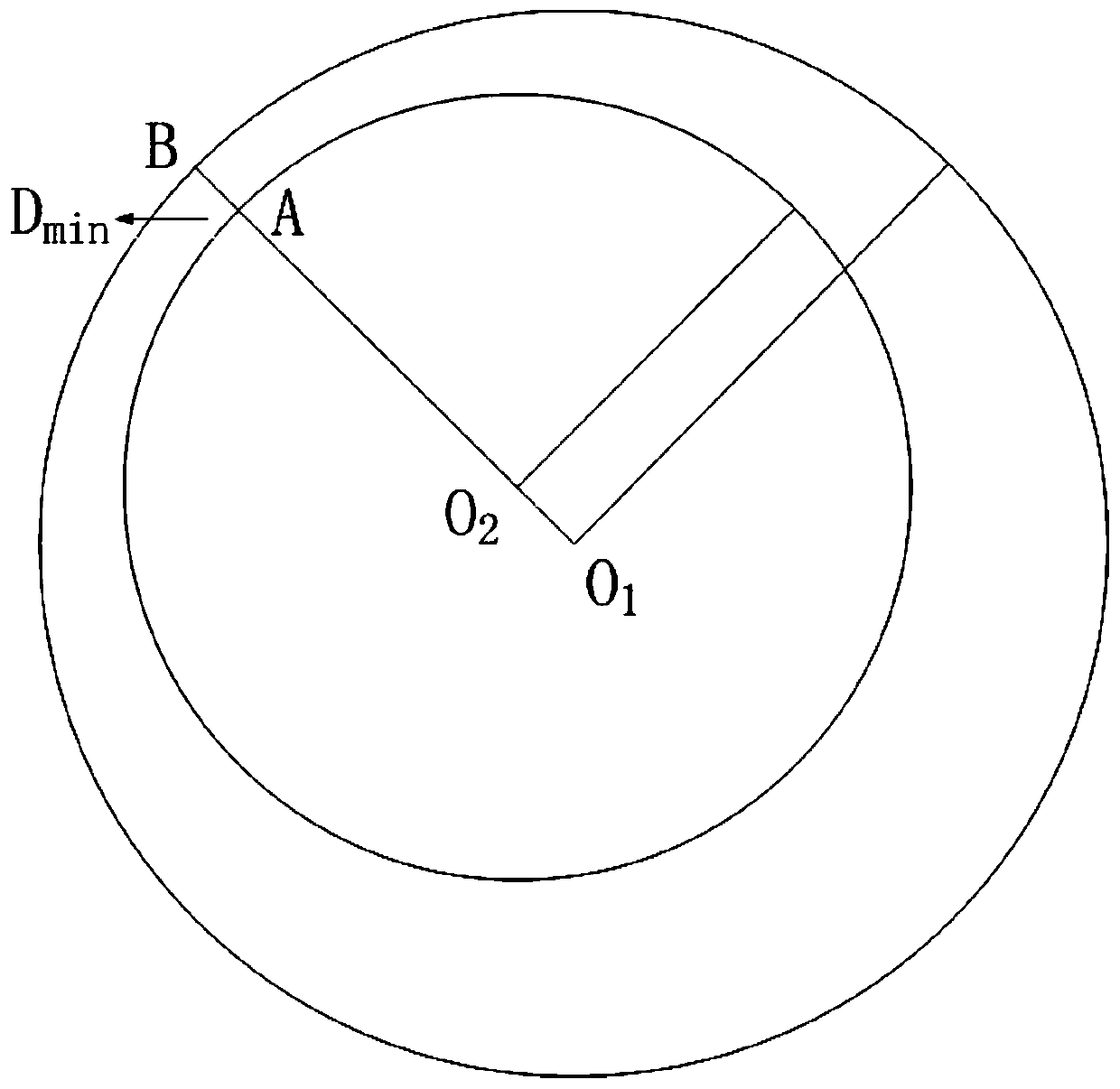

[0075] For radial bearings, the radial clearance under working conditions can be obtained by the following formula:

[0076] u r = u 0 +Δu a +Δu T ;

[0077] Among them, u r -- Radial clearance of the bearing in working condition;

[0078] u 0 --The initial design radial clearance u of the bearing 0 ;

[0079] Δu a --The change in radial clearance o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com