Full-wave-direction ship sea keeping performance tester

A tester and wave direction technology, which is applied in the field of full wave direction ship seakeeping performance tester, can solve problems such as difficult measurement, missing, adverse effects of ship design, etc., and achieve the effect of wide measurement range and measurement conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further elaborated below by specific embodiment:

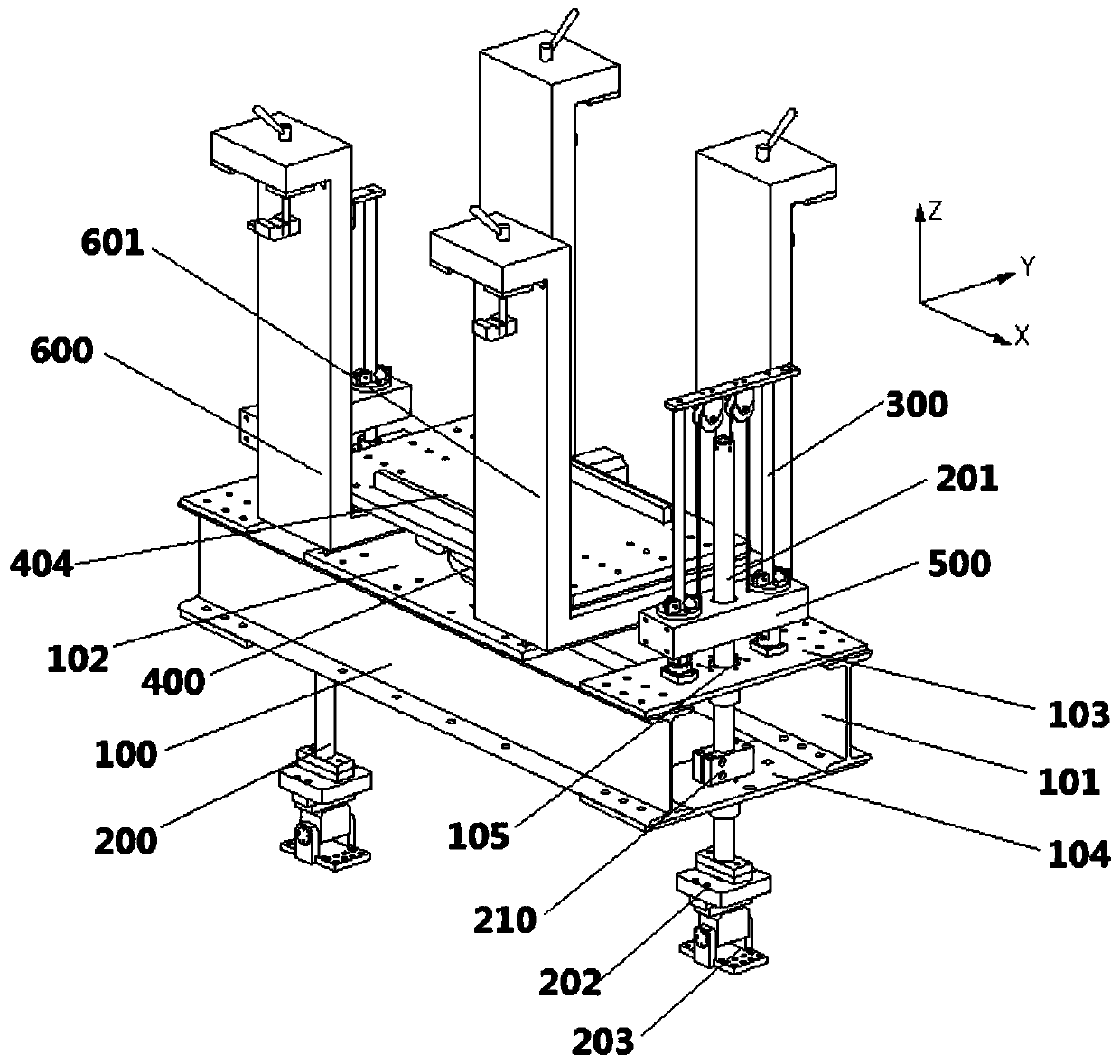

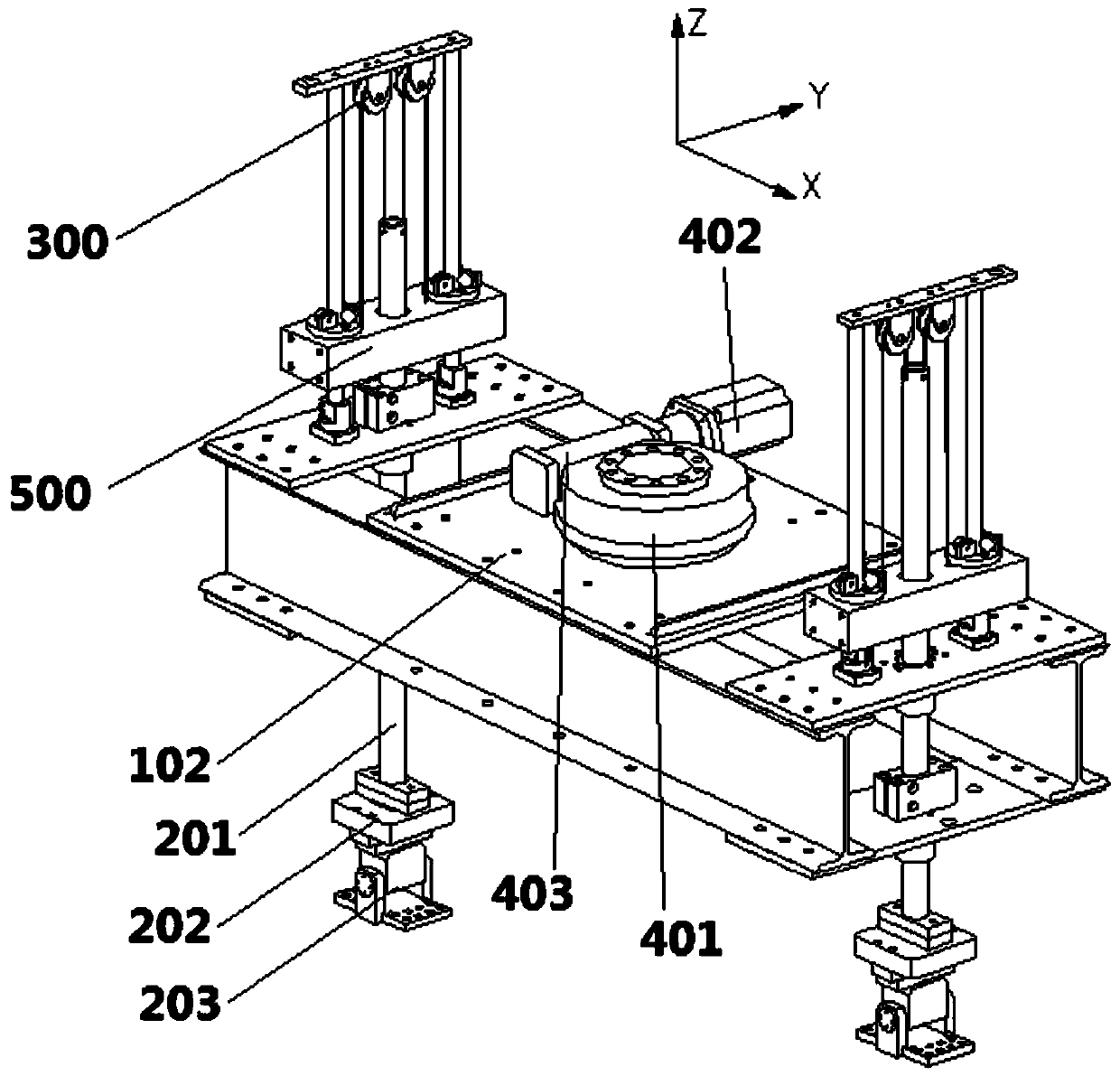

[0028] Such as figure 1 As shown, the all-wave ship seakeeping performance tester of the present invention includes a support frame 100 , a test rod 200 , a gantry frame 300 , a steering drive mechanism 400 , a counterweight 500 and a connecting frame 600 .

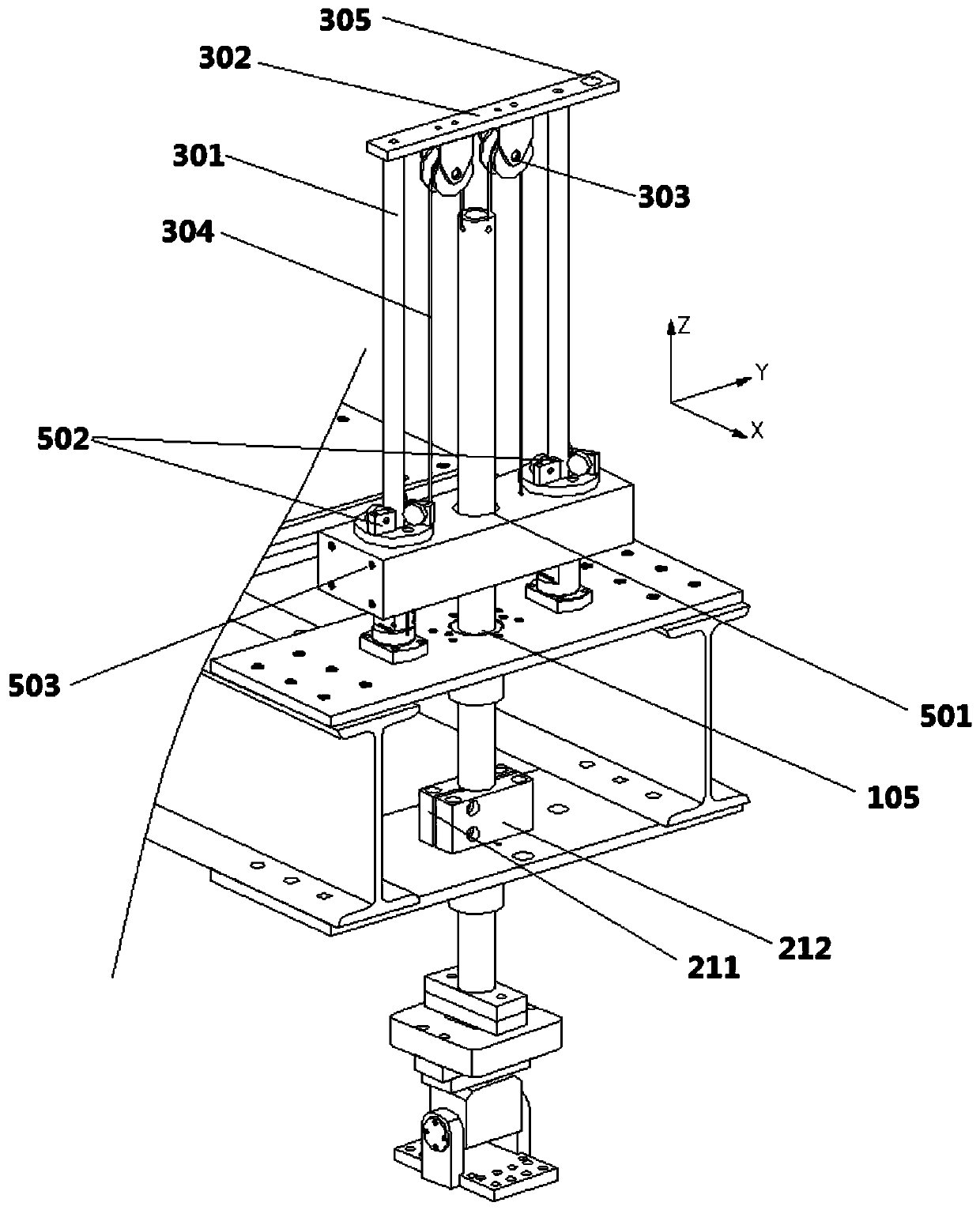

[0029] Wherein, the support frame 100 is composed of two I-beams 101 arranged in parallel, an intermediate support plate 102 connected across the middle of the upper surface of the two I-beams 101, and respectively straddling and connected to the upper and lower ends of the two I-beams. The end upper support plate 103 and the end lower support plate 104 of the surface are formed. The middle positions of the upper support plate 103 at the end and the lower support plate 104 have perforations 105 aligned up and down.

[0030] The test rod 200 is composed of a long rod 201 , a three-component force sensor 202 and a ship model connector 203 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com