Safety lifting appliance capable of automatic hooking and unhooking

A safety and spreader technology, applied in the direction of load hanging components, transportation and packaging, etc., to achieve the effect of preventing false hanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

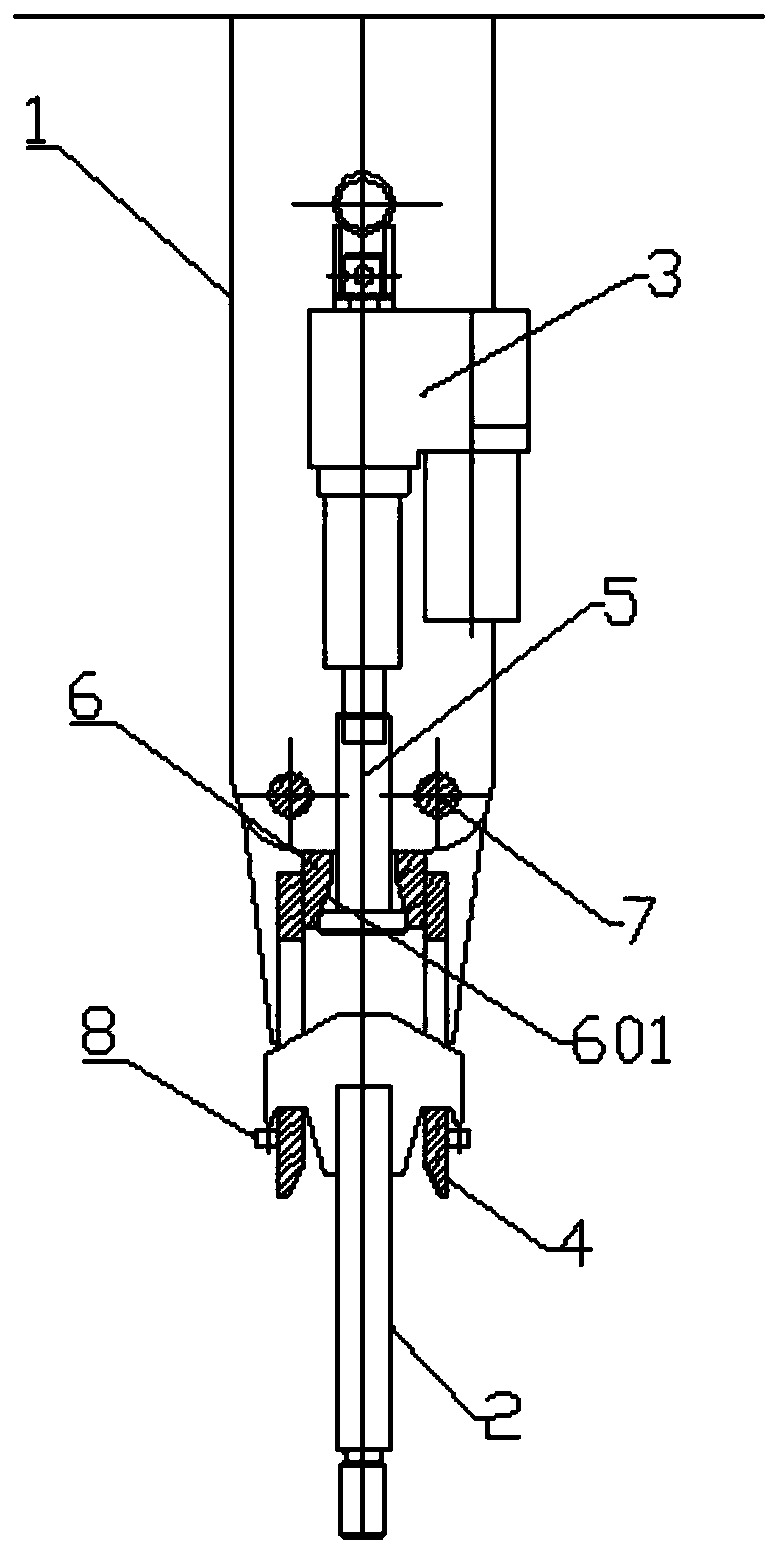

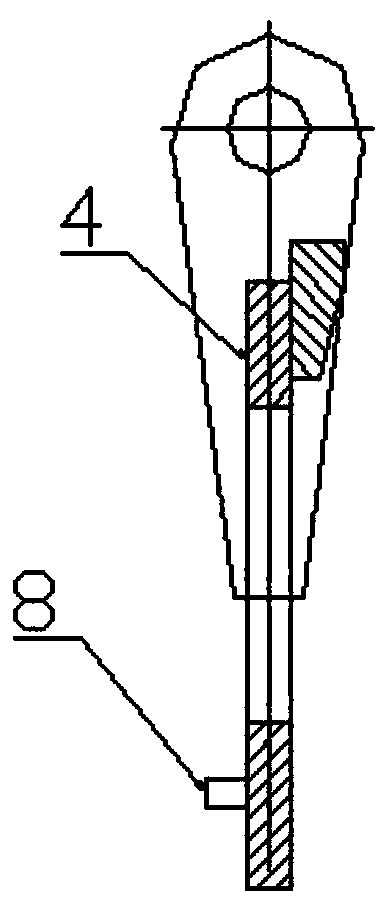

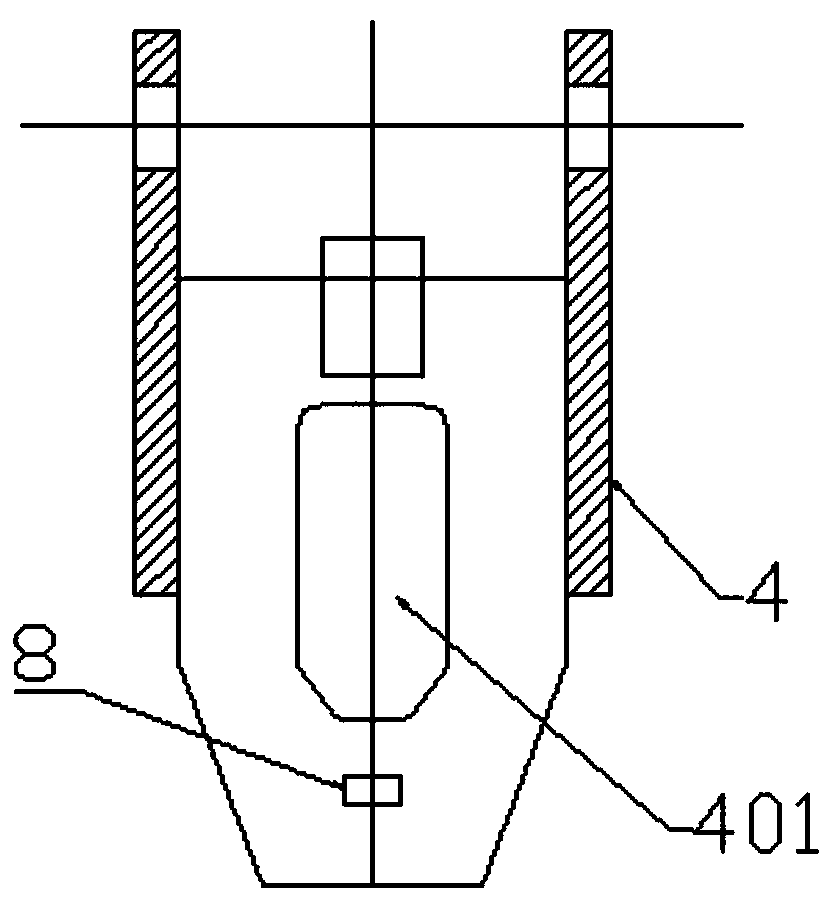

[0020] Such as figure 1 , 2 , 3, 4, and 5 show a specific embodiment of an automatic unhooking safety hanger, including a main body 1, a hanging nail 2 and a driving device 3 installed on the main body 1. The main body 1 is hinged with two hook plates 4 through the rotating shaft 7 at opposite positions, so that the two hook plates can rotate around the rotating shaft to realize the separation / closing of the lower ends of the two hook plates. The driving device 3 is used to drive the two hook plates 4 to turn over in the opposite direction to separate them. Specifically, the driving device 3 is an up and down driving device, and the telescopic end of the driving device 3 is equipped with a driving body 5. The driving device in the example used an electric push rod, and the driving body was installed on the rod end of the electric pushing rod, so that the driving device drove the driving body to move up and down. The inner sides of the two hook plates 4 are provided with a gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com