Oil bottle capable of quantitatively pouring oil

An oil bottle and oil pouring technology, which is applied in packaging, distribution devices, transportation and packaging, etc., can solve the problems of cumbersome operation, poor user experience, and sometimes too little oil poured out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

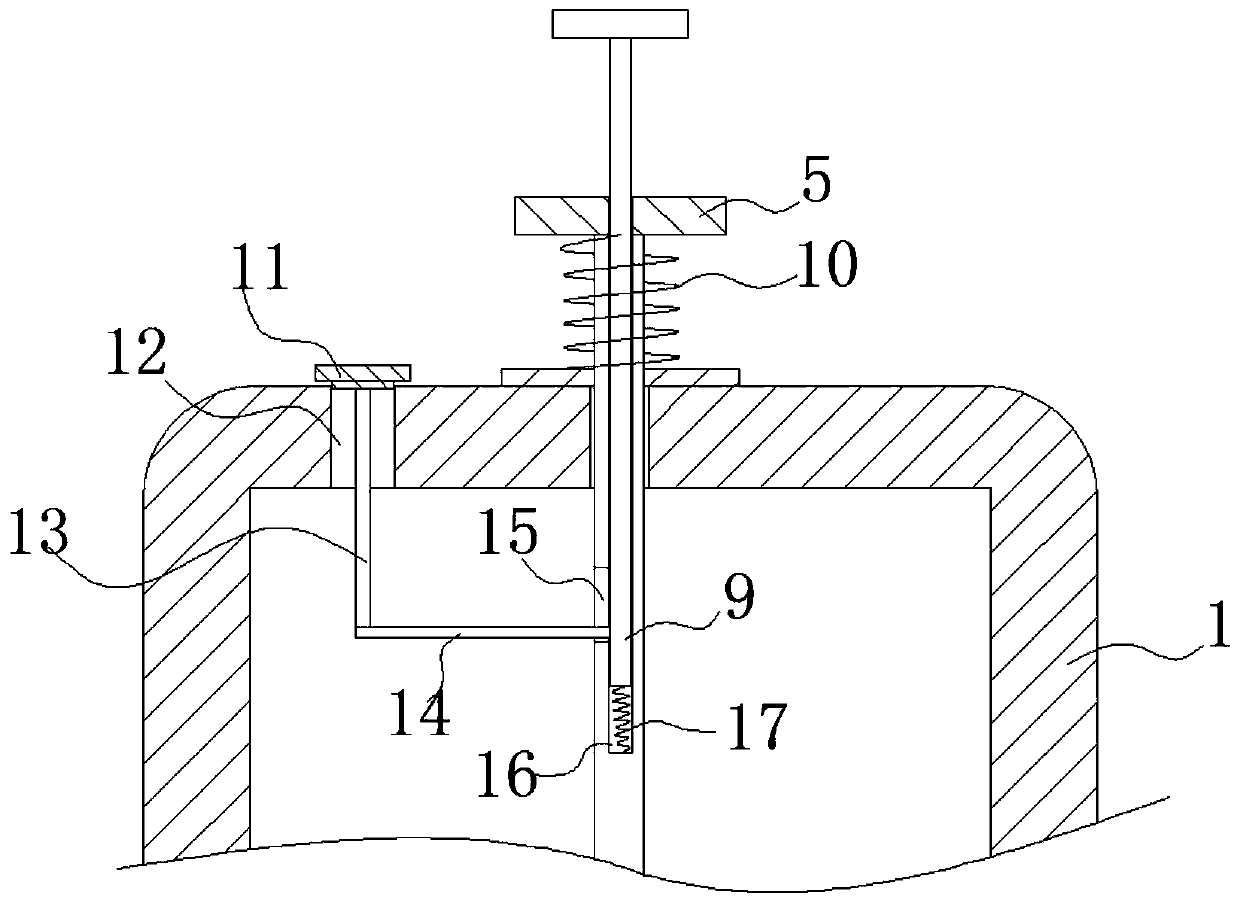

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

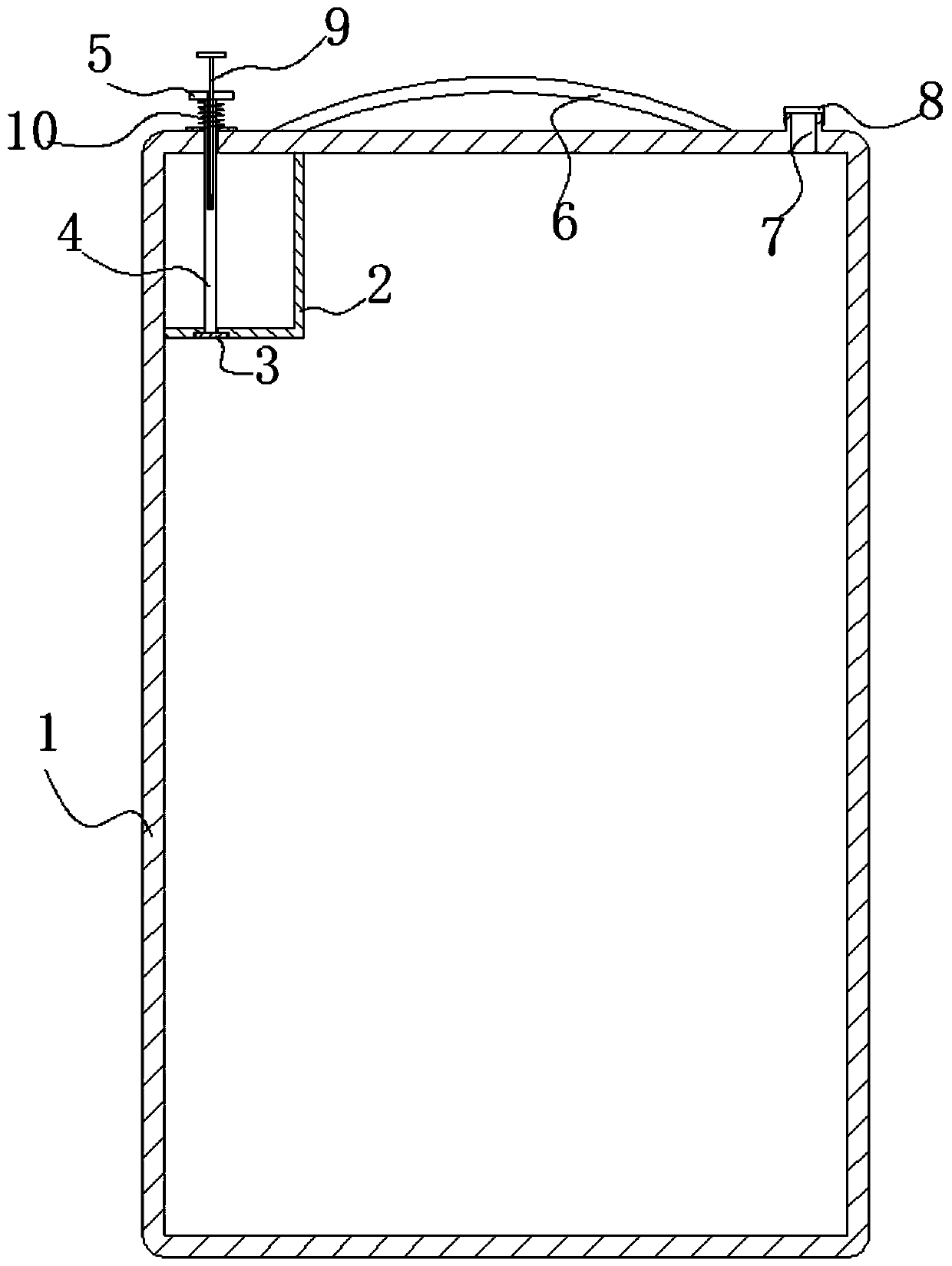

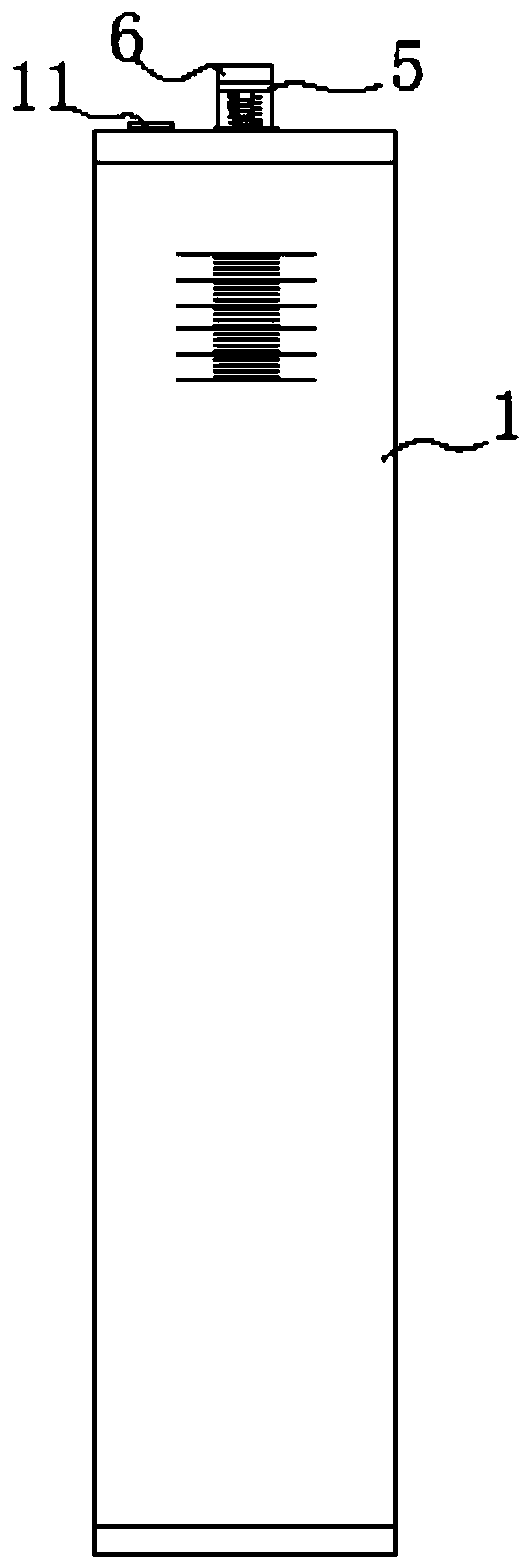

[0016] refer to Figure 1-3 , an oil bottle capable of quantitatively pouring oil, comprising an oil bottle 1, an oil inlet hole 7 is opened on the top side of the oil bottle 1, and a sealing cover 8 is set on the outer side of the oil inlet hole 7, and the oil bottle 1 passes through the oil inlet hole 7 Quickly inject oil, the top partition 2 inside the oil bottle 1, the partition 2 and the oil bottle 1 divide the inside of the oil bottle 1 into two spaces, and the sealed space formed by the partition 2 and the inner wall of the oil bottle 1 is used to store quantitative Oil.

[0017] A pull rod 4 is inserted into the top of the oil bottle 1, and one end of the pu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap