A responsive material based on semi-interpenetrating polymer network and its application

A polymer and semi-interpenetrating technology, applied in the field of liquid crystal materials, can solve the problems of losing temperature response properties and limiting the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a responsive material based on a semi-interpenetrating polymer network, which is prepared by the following steps:

[0027] (1) Weigh 77 parts by mass of liquid crystal elastomer and liquid crystal mixture to form a coating, the liquid crystal mixture includes 16 parts by mass of chiral polymerizable liquid crystal monomer RM-1, 5 parts by mass of achiral polymerizable liquid crystal monomer The photoinitiator of body RM-2, 1 mass part and the tensio-active agent of 1 mass part;

[0028] (2) The above-mentioned coating is coated on the polyimide glass substrate of rubbing using doctor blade coating, followed by UV polymerization (light intensity I=32mw / cm 2 , 10 minutes in a nitrogen atmosphere).

[0029] The structural formula of the liquid crystal elastomer used in this embodiment is that the structural formula of the liquid crystal elastomer is Chiral polymerizable liquid crystal monomer RM-1 is a left-handed liquid crystal monomer, and its...

Embodiment 2

[0032] This embodiment provides a patterned coating, prepared according to the following steps:

[0033] (1) the coating used in the present embodiment is the same as the coating composition of embodiment 1;

[0034] (2) The above-mentioned coating is coated on the rubbed polyimide glass substrate by flexographic printing process, and a photomask with a clover pattern is used to pass a 0.01mw / cm 2 The UV light intensity is irradiated, and the patterned area is surrounded by 2.7mw / cm 2 intensity of irradiation.

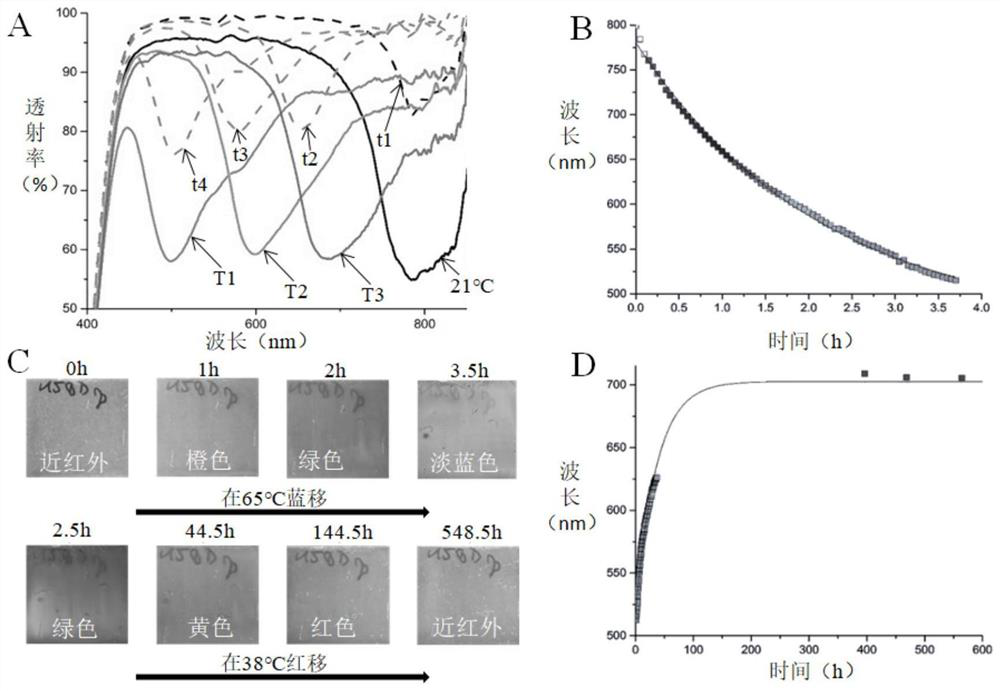

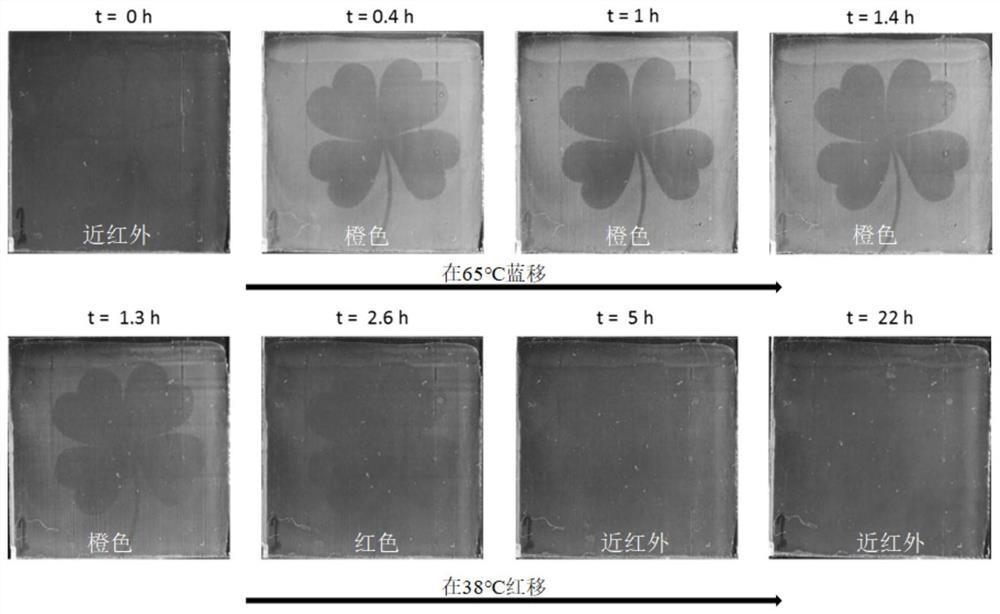

[0035] The pictures of the above patterned coatings taken in different temperature-time processes are as follows: figure 2 As shown, it can be seen from the figure that the surrounding area of the clover pattern becomes visible at high temperature (65°C) and becomes invisible at lower temperature (28°C). Due to different polymerization conditions, the clover-patterned area does not shift to visible wavelengths, and when heated to 65 °C within 1.4 h, the surroundi...

Embodiment 3

[0037] This embodiment provides a temperature-responsive coating, which is prepared through the following steps. The raw materials used in this embodiment are the same as those in Embodiment 1:

[0038] (1) Weigh 80 parts by mass of liquid crystal elastomer and liquid crystal mixture to form a coating, the liquid crystal mixture includes 5 parts by mass of chiral polymerizable liquid crystal monomer RM-1, 11 parts by mass of achiral polymerizable liquid crystal monomer The photoinitiator of body RM-2, 2 mass parts and the tensio-active agent of 2 mass parts;

[0039] (2) The above-mentioned coating is coated on the polyimide glass substrate of rubbing using doctor blade coating, followed by UV polymerization (light intensity I=32mw / cm 2 , 10 minutes in a nitrogen atmosphere).

[0040] Observing the changes of the temperature-responsive coating of this embodiment in different temperature-time courses shows that the color of the temperature-responsive coating changes with tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com