a film roll

A film core and plastic film technology, applied in the core field, can solve the problems of uneven film surface, uneven internal stress release, slow release of internal stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

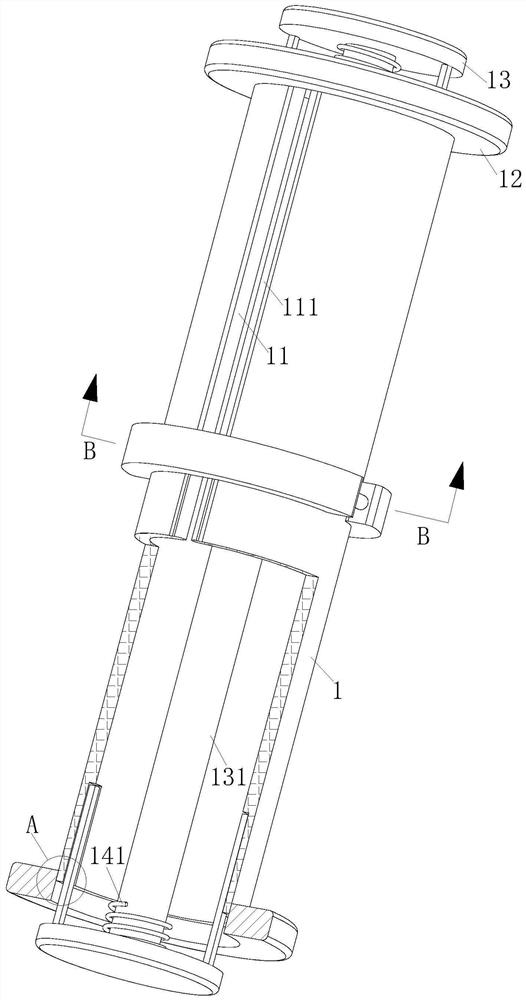

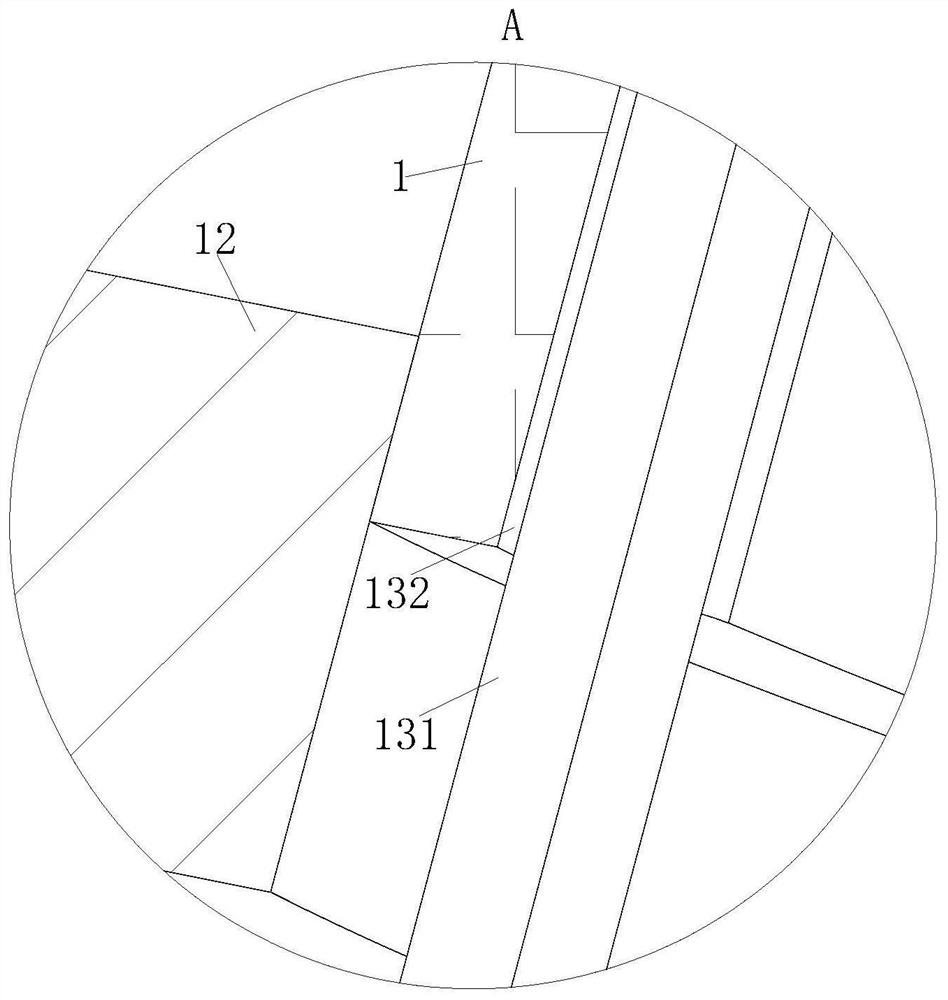

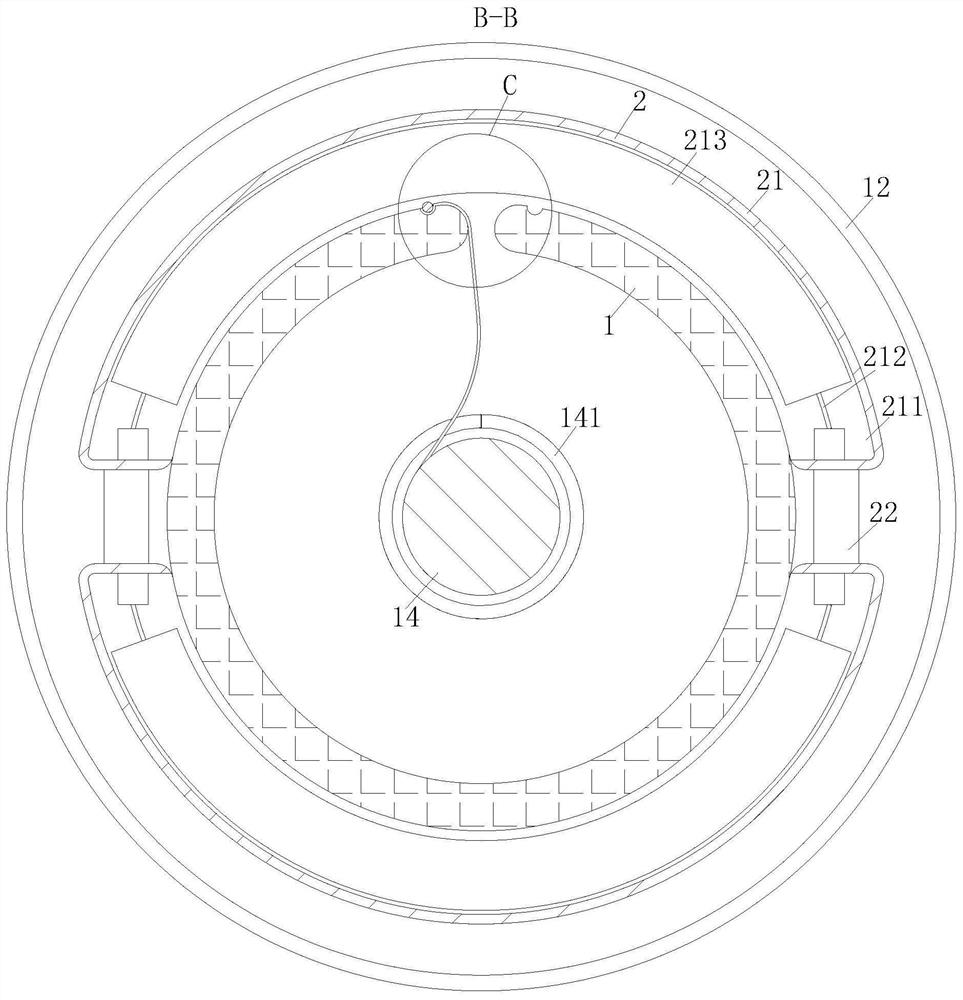

[0023] As a specific embodiment of the present invention, No. 1 slot 111 is respectively provided on both sides of said No. 1 slot 11, and the length of No. 2 slot 111 is the same as that of No. 1 slot 11, and one of No. 2 slot 111 is provided with There is a metal rod 112; the metal rod 112 is embedded in the No. 2 groove 111; through the cooperation between the No. 2 groove 111 and the metal rod 112, the pressing and fastening of the plastic film on the outer ring surface of the body 1 is realized; When the plastic film is pulled out from the body 1 and attached to the surface of the body 1, one end of the plastic film can be placed in the second slot 111, and then embedded in the second slot 111 through the metal rod 112, and the metal rod 112 Press the plastic film in the No. 2 groove 111, so that the film can be rolled up without manually fixing the plastic film, which frees the hands of the operator. The plastic film is retracted on the winding roller 14, and one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com