Steel-structure horizontal sliding guide rail oil scraping device and construction method thereof

An oil-scraping device and a water-sliding technology, which are applied to the surface coating liquid device, lubricating parts, engine lubrication, etc., can solve problems such as difficult adaptation, uneven oiling, and difficult operation of oil scraping blades, and achieve Easy to reuse, easy to install and replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

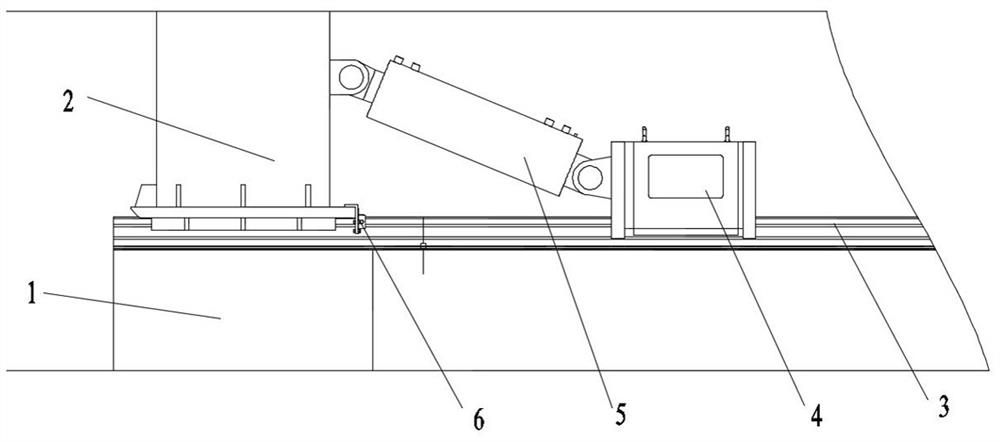

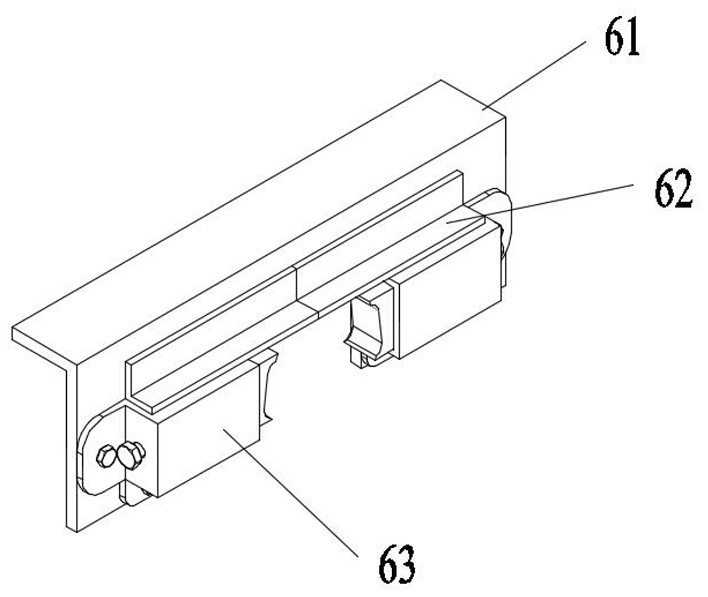

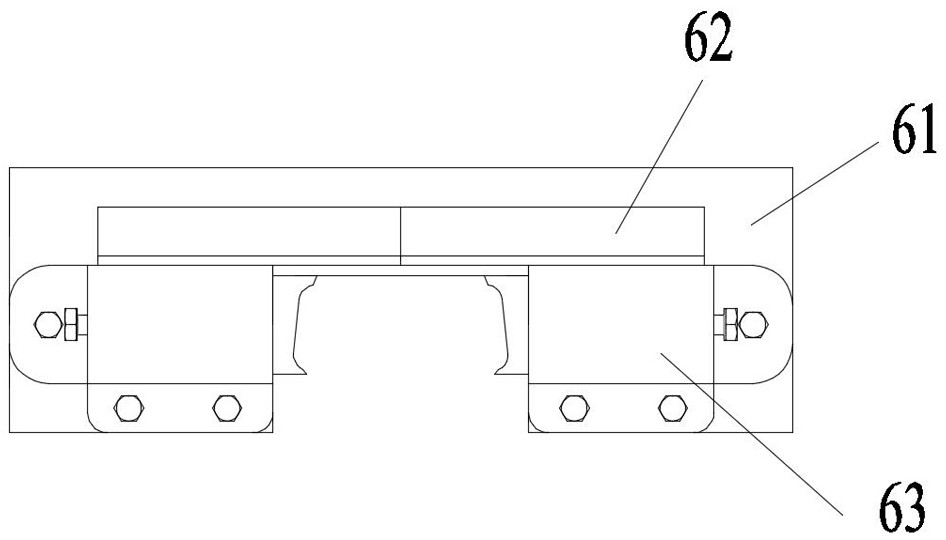

[0037] like figure 1 As shown, a steel structure horizontal sliding guide rail oil scraping device includes a sliding rail 3, a sliding shoe 2 connected to the sliding rail 3, and a locking device 4 connected to the sliding rail 3 and located in the opposite direction of the forwarding of the sliding shoe 2. , a hydraulic cylinder 5 connected between the sliding shoe 2 and the locking device 4 and an oil scraping mechanism 6 connected to the bottom of the sliding shoe 2 and connected to the sliding rail 3 .

[0038] In this embodiment, a slide rail 3 is laid above the upright column 1 . The slide rail 3 is an I-shaped steel rail, and the steel rail is a straight line. During the sliding construction, oil is applied to the outer surface of the slide rail 3 . The sliding shoe 2 and the locking device 4 on the sliding rail 3 are respectively detachably connected with the hydraulic cylinder 5 through lugs.

[0039] In this embodiment, the fixed support is made of steel, the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com