Cutting structure for V-belt cutting machine and V-belt cutting machine

A V-belt and cutting machine technology, which is applied in metal processing and other directions, can solve the problems of unqualified dimensions of the V-belt blank layer, achieve the effects of improving pre-cutting accuracy, improving surface smoothness, and avoiding lateral misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

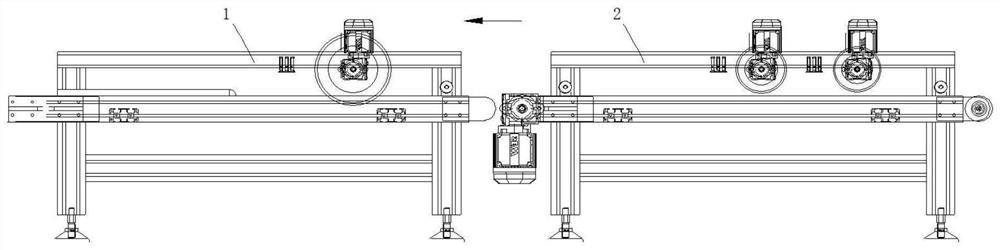

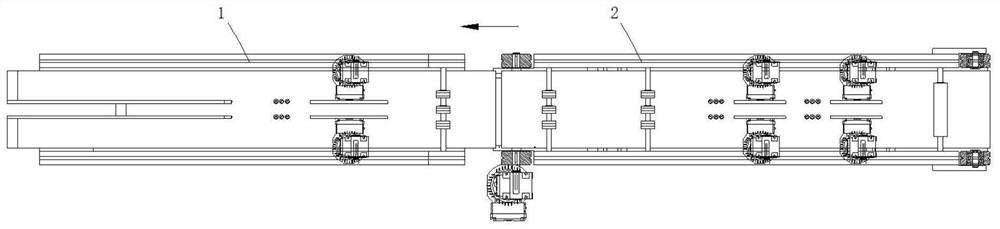

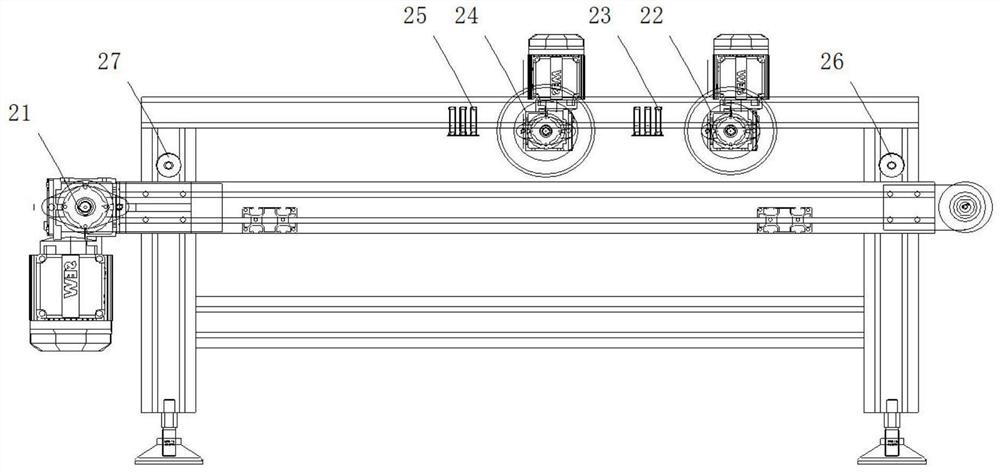

[0058] Such as Figure 1 to Figure 10 As shown, the cutting structure for the V-belt cutting machine described in the embodiment of the present invention includes a cutting frame 1 for cutting the V-belt into strips, a pre-cutting frame 2 for cutting a part of the upper surface of the V-belt, Along the delivery direction (shown in the direction of the arrow) of the V-belt cutting machine, the tail end of the pre-cutting frame 2 is connected with the head end of the cutting frame 1, and the pre-cutting frame 2 includes

[0059] The first conveyor 21 is used to transport the V-belt to be cut, and the first conveyor 21 extends along the conveying direction of the V-belt cutting machine;

[0060] At least one pressing wheel 22 is driven by a motor, and is used to form a pre-cut recess extending along the conveying direction of the V-belt cutting machine on the upper surface of the V-belt to be cut, and the pressing wheel 22 and the first conveying The conveyor 21 is rotatably con...

Embodiment 2

[0088] Such as Figure 11 to Figure 15 As shown, the present invention also discloses a V-belt cutting machine, including a cutting structure for a V-belt cutting machine and a material guide frame 3, and the cutting structure for a V-belt cutting machine is for the V-belt cutting machine described in Embodiment 1. Cutting structure, the V-belt cutting machine connects the tail end of the material guide frame 3 with the head end of the cutting structure.

[0089] In order to guide the V-belt to be cut, the material guide frame 3 includes at least one second positioning roller 31, the second positioning roller 31 is rotationally connected with the material guide frame 3, and the second positioning roller 31 Relative to the upper surface of the material guide frame 3, the upper surface is suspended, the axial extension of the second positioning roller 31 extends in the horizontal direction, and the axial direction of the second positioning roller 31 is vertical to the conveying ...

Embodiment 3

[0091] Such as Figure 16 As shown, a plurality of the second positioning rollers 31 can also be provided, and the plurality of the second positioning rollers 31 are arranged at intervals along the extending direction of the material guide frame 3 .

[0092] Refer to Example 2 for other undescribed structures.

[0093] It should be noted that in this article, relational terms such as first and second are only used to distinguish one entity or operation from another entity or operation, and do not necessarily require or imply that there is a relationship between these entities or operations. There is no such actual relationship or order between them.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com