A method and device for controlling dynamic steel tapping at the eccentric furnace bottom of a converter

An eccentric furnace bottom and control method technology, which is applied in the field of metallurgy, can solve the problems of molten steel suction, secondary oxidation, and large amount of slag, so as to improve work efficiency, stabilize steel tapping, and avoid molten steel suction and secondary oxidation. The effect of secondary oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

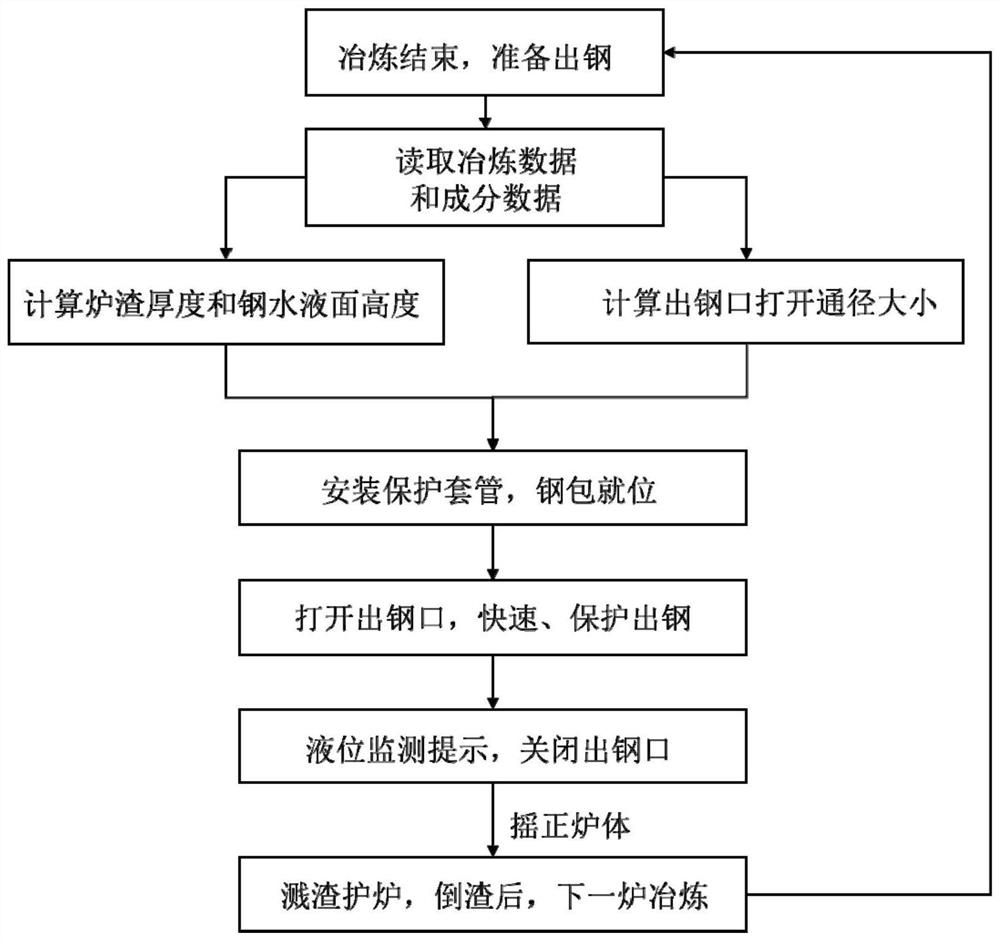

[0107] In the specific embodiment of the present invention, the dynamic tapping method of the eccentric furnace bottom of the converter is as follows: Figure 7 As shown, for the 120t drum spherical converter, the following steps are taken when the smelting is finished and the steel is ready to be tapped:

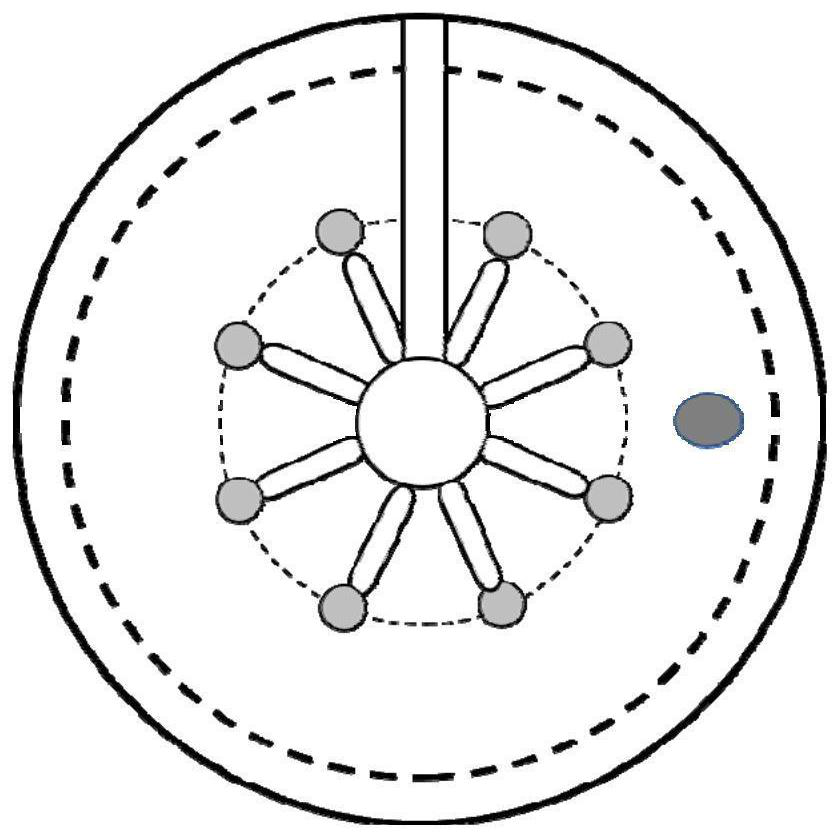

[0108] (1) Turn the converter to 30°, and turn the taphole to the lowest point, in a vertical state, and perpendicular to the horizontal plane, such as Figure 6 shown.

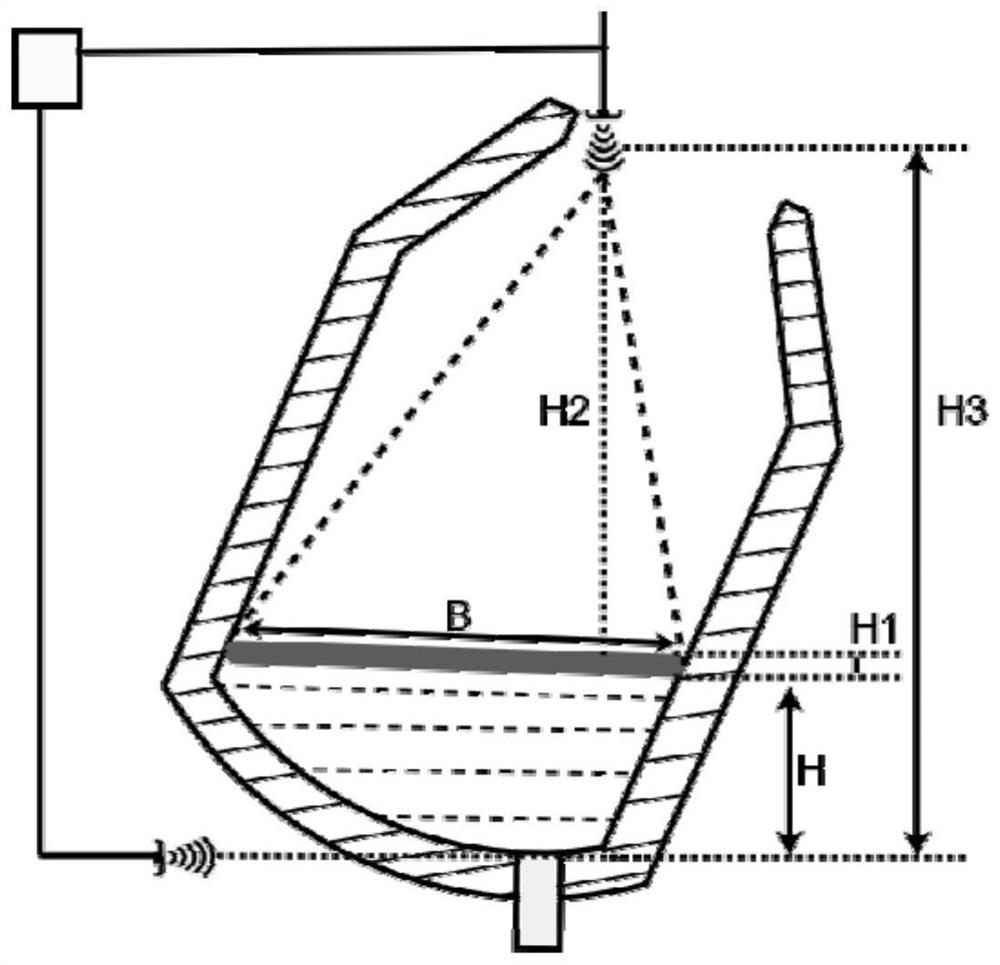

[0109] (2) Calculate the thickness of the slag and calibrate the height of the molten steel pool:

[0110] First, collect the material information of the current heat, the specific information is:

[0111] Table 1 The amount of raw and auxiliary materials added

[0112]

[0113] Table 2 Metal Material Component Parameters

[0114] type C Si mn P S T molten iron 4.5 0.3425 0.163 0.1196 0.0254 1386 scrap steel 0.18 0.2 0.92 0.023 0.025 25 TSO test 0.111 0...

Embodiment 2

[0152] This embodiment is similar to Embodiment 1, but for a 200t converter, its dynamic tapping operation can be simply described as:

[0153] (1) Turn the converter to 32° so that the tapping hole is at the lowest point, perpendicular to the horizontal plane.

[0154] (2) Extract the charging information and end point information of the current heat, calculate the initial slag thickness to be 0.092m, and calibrate the initial molten steel liquid level height to be 1.25m.

[0155] (3) The diameter of the tap hole is 20.35cm. Select a protective casing with a diameter of 30.5cm, put it on the tapping hole, move the ladle car to the right below the tapping hole, use the ladle car elevator to raise the height of the ladle, make the protective casing immerse 0.5m inside the ladle, and turn on the argon gas in the ladle Bottom blow.

[0156] (4) At the end of converter smelting, the temperature drop rate is 10°C / min, the molten steel temperature measured based on TSO is 1710°C, ...

Embodiment 3

[0162] This embodiment is similar to Embodiment 1, but for the 300t converter, its dynamic tapping operation can be simply described as:

[0163] (1) Turn the converter to 35° so that the tapping hole is at the lowest point, perpendicular to the horizontal plane.

[0164] (2) Extract the charging information and end point information of the current heat, calculate the initial slag thickness to be 0.112m, and calibrate the initial molten steel liquid level height to be 1.65m.

[0165] (3) The diameter of the tapping hole is 24.25cm. Select a protective casing with a diameter of 36.5cm and put it on the tapping hole. Move the ladle car to the right below the tapping hole, and use the ladle car lift to raise the height of the ladle so that the protective casing Immerse at 0.5m inside the ladle, and start the argon bottom blowing of the ladle.

[0166] (4) At the end of converter smelting, the temperature drop rate is 10°C / min, the molten steel temperature measured based on TSO i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com