Regeneration method of ink container and regenerated ink container

An ink container and ink sac technology, applied in printing and other directions, can solve the problems of wear on the edge of the circuit board shell, complicated processes, and difficulty in controlling the precision of openings, and achieve the effect of simplifying the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the present invention are described below in conjunction with the accompanying drawings.

[0043] [Combination of print head case and ink bag]

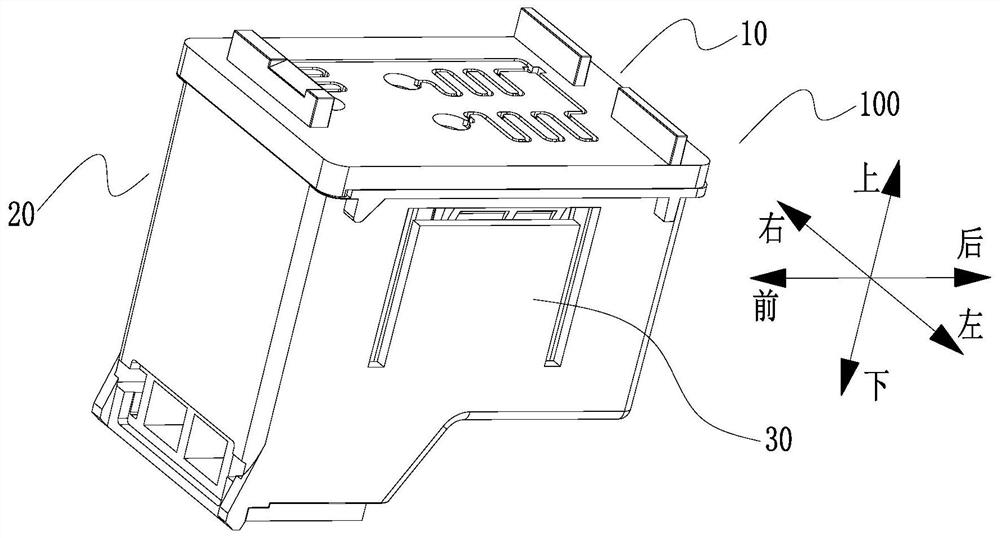

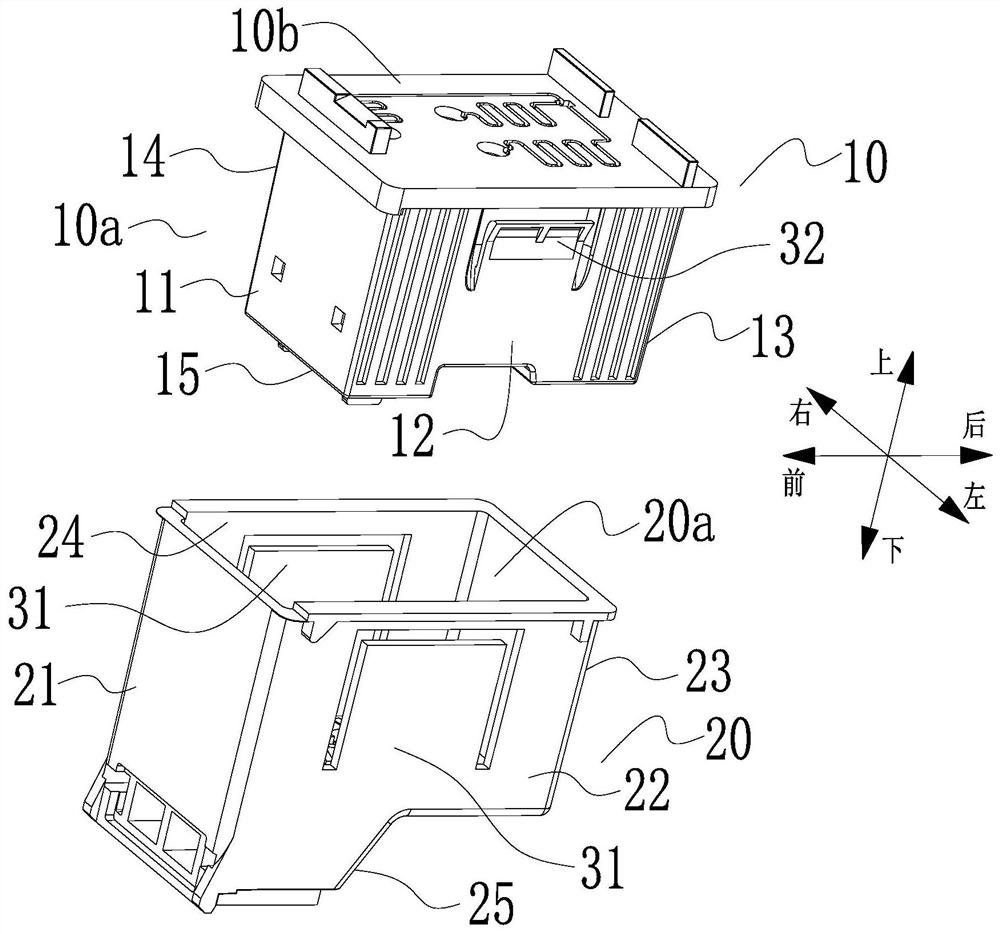

[0044] figure 1 is a perspective view of an ink container according to the present invention; figure 2 It is an exploded perspective view of the ink bag and the print head housing in the ink container of the present invention.

[0045] Before describing in detail, first combine the figure 1 The orientation of the ink container 100 is defined as follows:

[0046] After the ink container 100 is detachably mounted on the inkjet imaging device, the height direction of the ink container is the up-down direction, the length direction of the ink container is the front-rear direction, and the width direction of the ink container is the left-right direction.

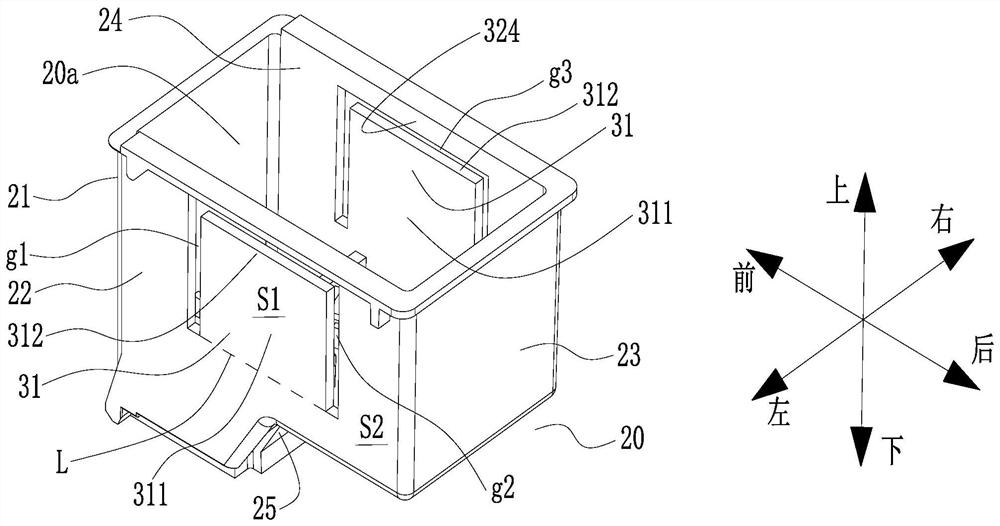

[0047] As shown in the figure, the ink container 100 includes an ink bag 10 and a printhead housing (bottom case) 20 and a control device 30 for combining and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com