Prefabricated one-way laminated slab abutted seam reinforcing structure

A technology for strengthening structures and laminated slabs, which is applied to floors, building components, building structures, etc., can solve problems such as gap widening, one-way slabs without relatively reliable connection measures, and cracking, and achieve the effect of reliable connection structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

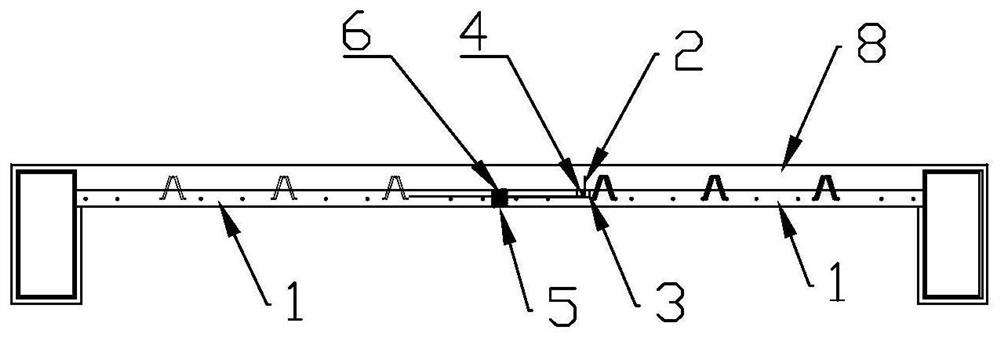

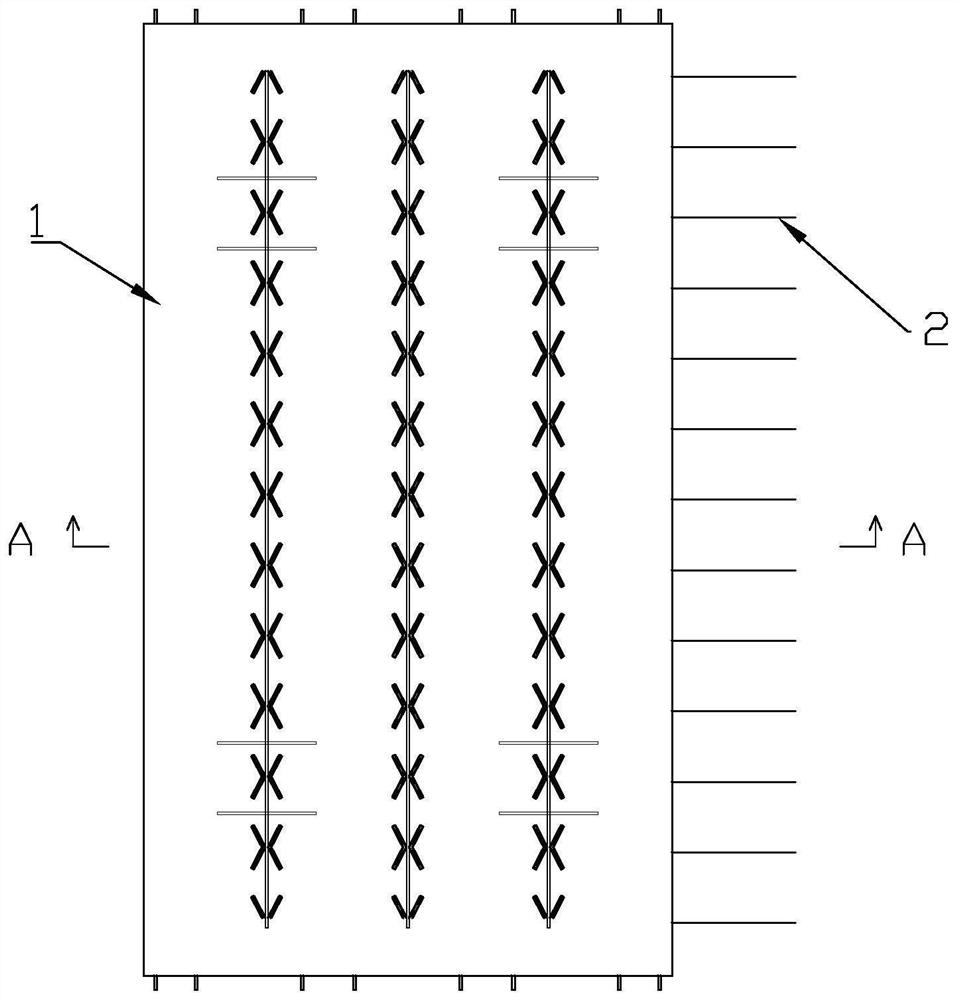

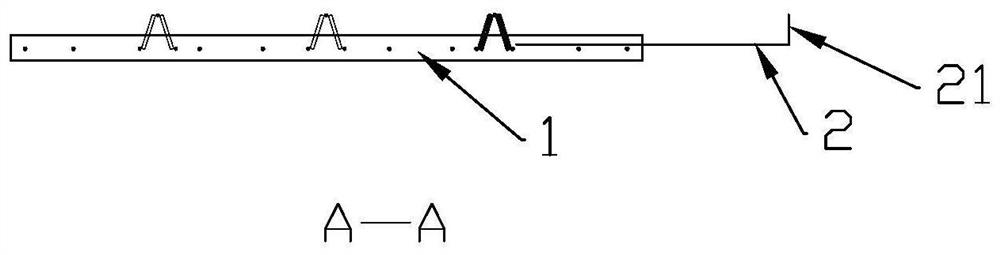

[0026] Refer to the attached figure 1 to attach Figure 13 The joint reinforcement structure of prefabricated unidirectional laminated boards of the present invention will be described in detail below.

[0027] The joint reinforcement structure of the prefabricated one-way laminated slabs of the present invention comprises more than two prefabricated slabs 1, and at the joint between two adjacent prefabricated slabs 1, a connection steel bar 2 is reserved for one, and a groove is reserved for the other 3. The connecting steel bars 2 include multiple connecting steel bars 2 respectively extending into the groove 3 and matching with the groove 3 , and the ends of the connecting steel bars 2 are connected by a structural steel bar 4 .

[0028] The groove 3 includes a parallel groove 31 parallel to the connecting steel bar 2 and a vertical groove 32 perpendicular to the connecting steel bar 2. The parallel groove 31 includes a plurality of vertical grooves 32 located at the ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com