Profile stretch bending equipment

A profile and equipment technology, applied in the field of profile stretch bending equipment, can solve the problems of reducing work efficiency, wasting manpower, increasing labor force, etc., and achieve the effect of improving efficiency, ensuring the quality of stretch bending, and improving the degree of cooperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

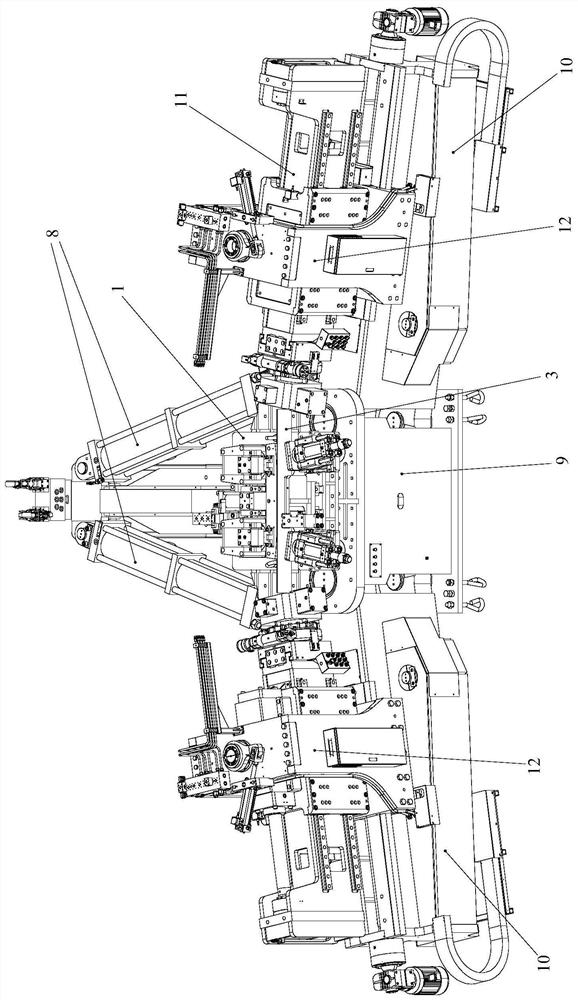

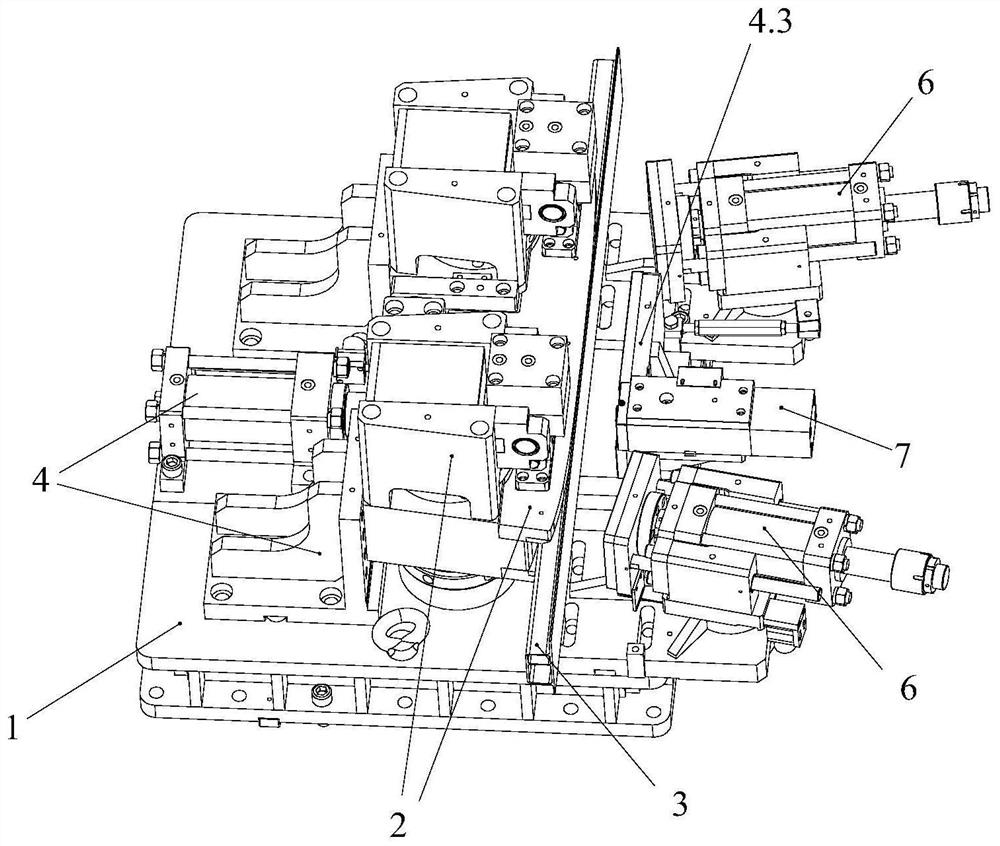

[0071] Such as Figure 1 to Figure 23 As shown, the profile stretch bending equipment of the present invention comprises:

[0072] working platform;

[0073]Left swing arm assembly and right swing arm assembly for clamping and stretching both ends of the profile;

[0074] And a swing arm cylinder assembly 9 for driving the swing of the left swing arm assembly and the right swing arm assembly;

[0075] Wherein, the left swing arm assembly and the right swing arm assembly are respectively located on both sides of the working platform, and the swing arm oil cylinder assembly 9 is connected with the left swing arm assembly and the right swing arm assembly.

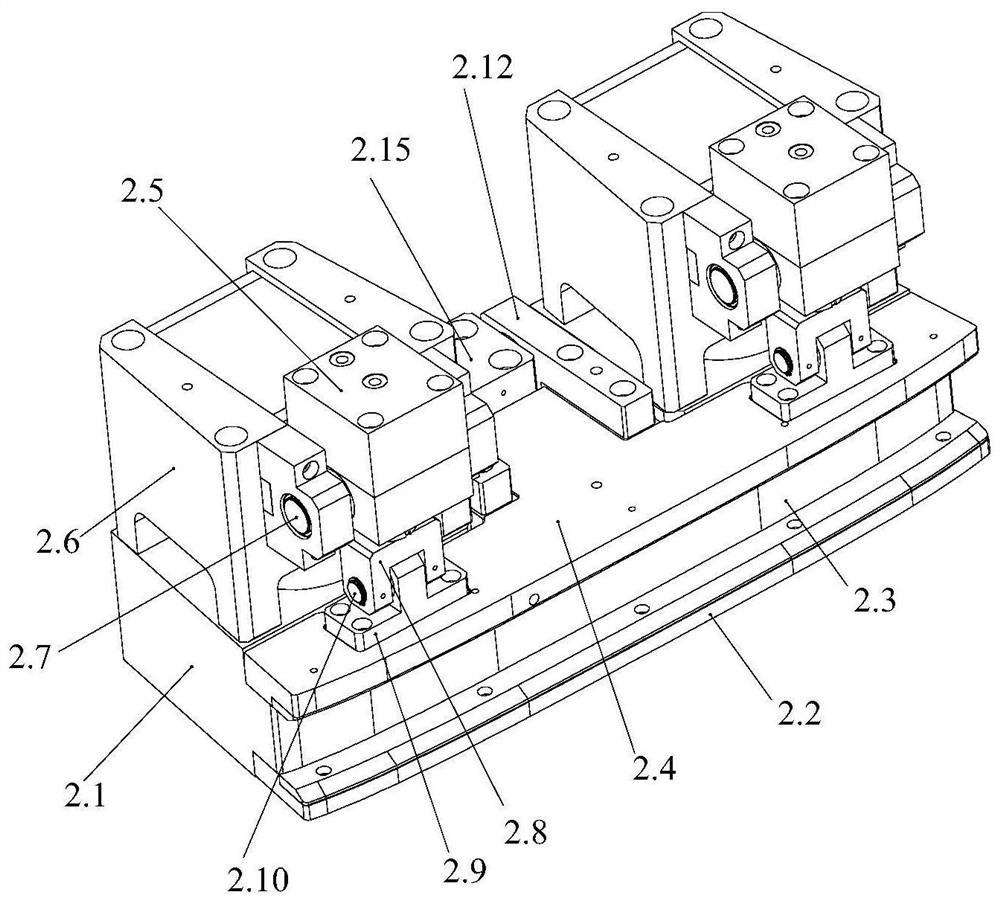

[0076] The working platform includes a platform base 8, a base 1, a pressing mechanism 2 for longitudinally positioning the profile 3, a horizontal positioning mechanism 4 for horizontally positioning the profile 3, and a horizontal positioning mechanism 4 for stretching and bending the profile 3. The tangent point position...

Embodiment 2

[0109] This embodiment differs from Embodiment 1 only in that: Figure 24 As shown, the mandrel of this embodiment includes a joint unit, the joint unit includes a joint part 12.8 and a mandrel rod 12.9, the joint part 12.8 is a movable detachable structure, and the joint part 12.8, the mandrel rod 12.9 and the mandrel are connected The rods 12.1 are in turn hinged and detachably connected.

[0110] The mandrel of this embodiment is suitable for the stretch bending process of only one cavity structural profile.

[0111] Other structures of this embodiment are consistent with Embodiment 1.

Embodiment 3

[0113] This embodiment differs from Embodiment 1 only in that: Figure 25 As shown, the joint part of the mandrel in this embodiment, the mandrel pull rod and the mandrel connecting rod 12.1 are connected sequentially, specifically: the joint part 1 of the joint unit 1 is hinged with the mandrel pull rod 12.2, and the joint part 2 of the joint unit 2 is connected with the mandrel rod 12.2. Mandrel tie rod two 12.5 are hinged, and mandrel tie rod one 12.2 and mandrel tie rod two 12.5 are connected with mandrel connecting rod 12.1 and are integrally structured to form a mandrel body.

[0114] Other structures of this embodiment are consistent with Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com