A working platform for profile stretch bending

A working platform and profile stretch bending technology, which is applied in the field of profile stretch bending processing, can solve the problems of complex positioning platform structure, affecting the quality of profile stretch bending, and difficulty in achieving positioning effects, so as to prevent warping or shifting and ensure tension The effect of improving bending quality and improving fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

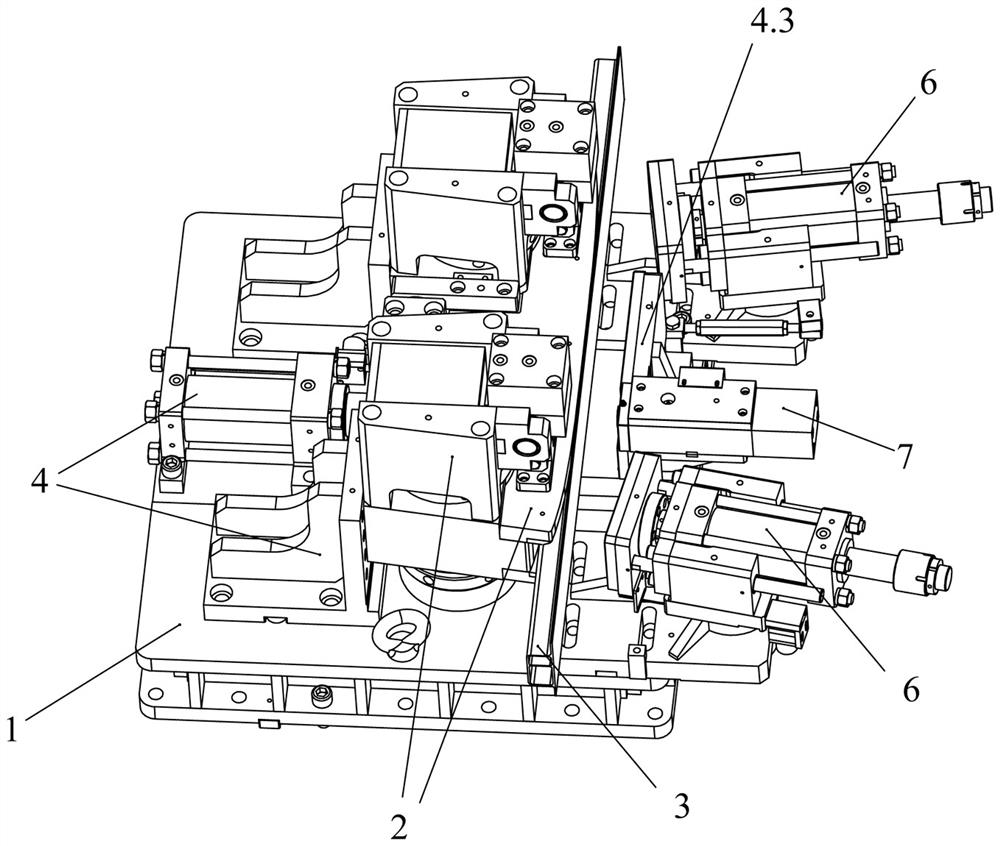

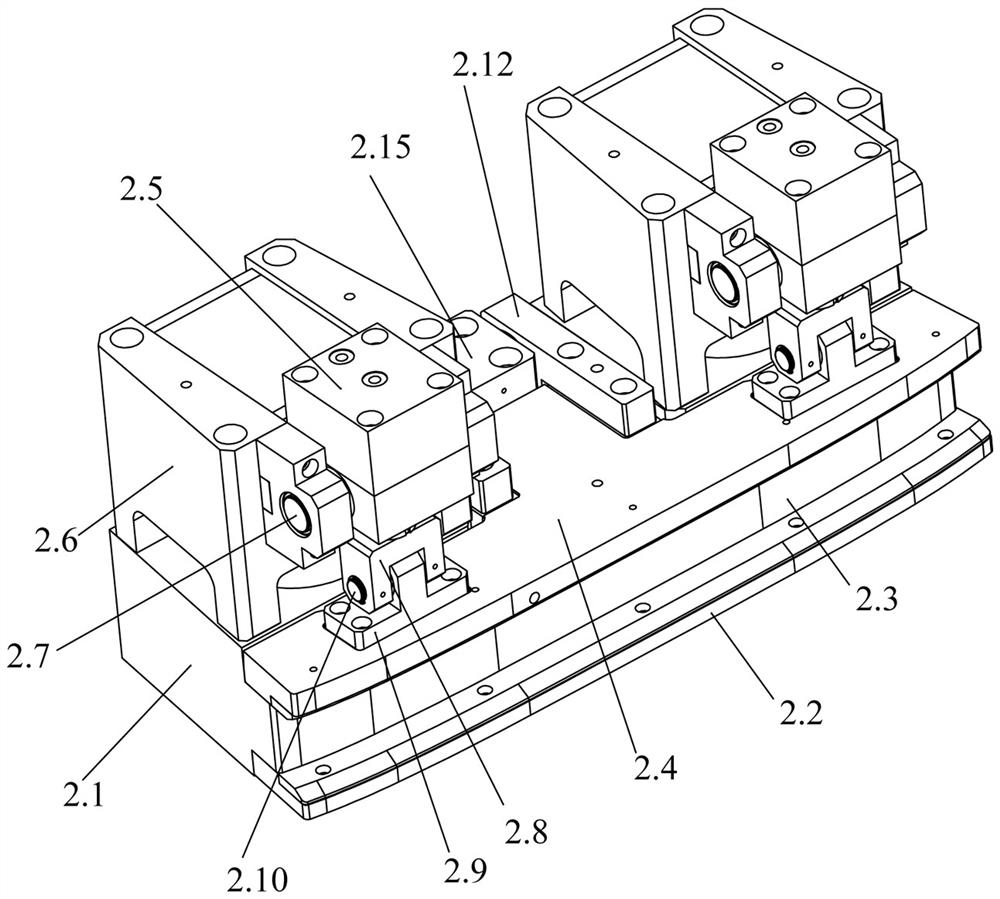

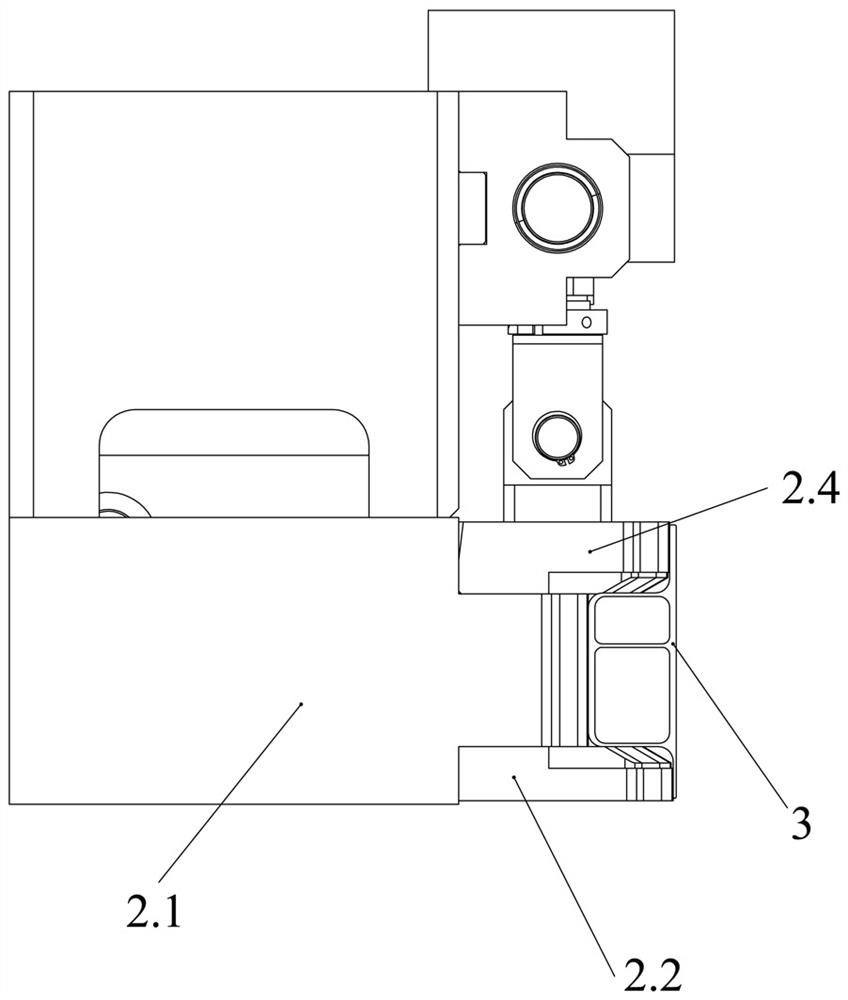

[0045] Such as Figure 1 to Figure 12 As shown, the positioning and pressing assembly for profile stretch bending of the present invention includes a base 1, a pressing and pressing mechanism 2 for longitudinally positioning the profile 3, and a horizontal positioning mechanism 4 for horizontally positioning the profile 3 And a tangent point positioning mechanism 6 for locating the tangent point when the profile 3 is stretched and bent, wherein the pressing and pressing mechanism 2 includes a mold core 2.1, a lower cover plate 2.2, and an upper cover plate 2.4 for pressing the profile 3 And the drive unit used to drive the upper cover plate 2.4 to lift and press down, wherein the drive unit is set to two, including the press-down oil cylinder 2.5, hinge shaft 1 2.7 and press-down oil cylinder mount 2.6, and press-down oil cylinder mount 2.6 It is arranged on the mold core 2.1, the lower cover plate 2.2 is connected with the mold core 2.1, and the lower pressure oil cylinder 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com