Pulling-out force test platform for gear selecting and shifting flexible shaft guide pipe

A technology of test platform and pull-off force, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., which can solve the problem of large errors, inability to effectively control and operate the applied time and rotation angle effort and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

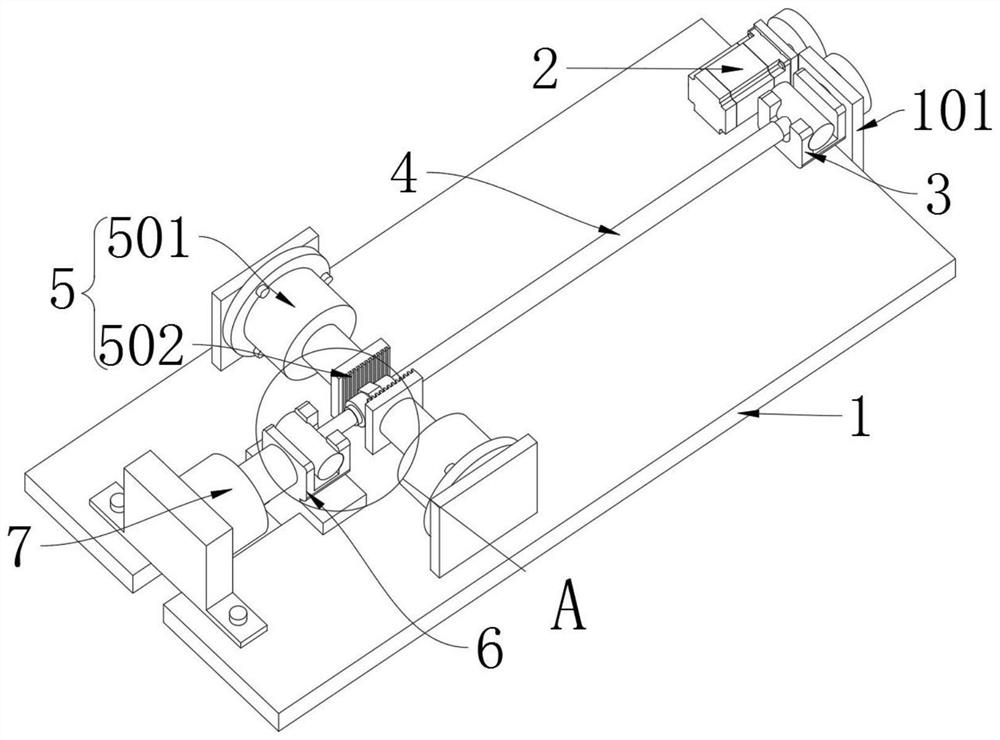

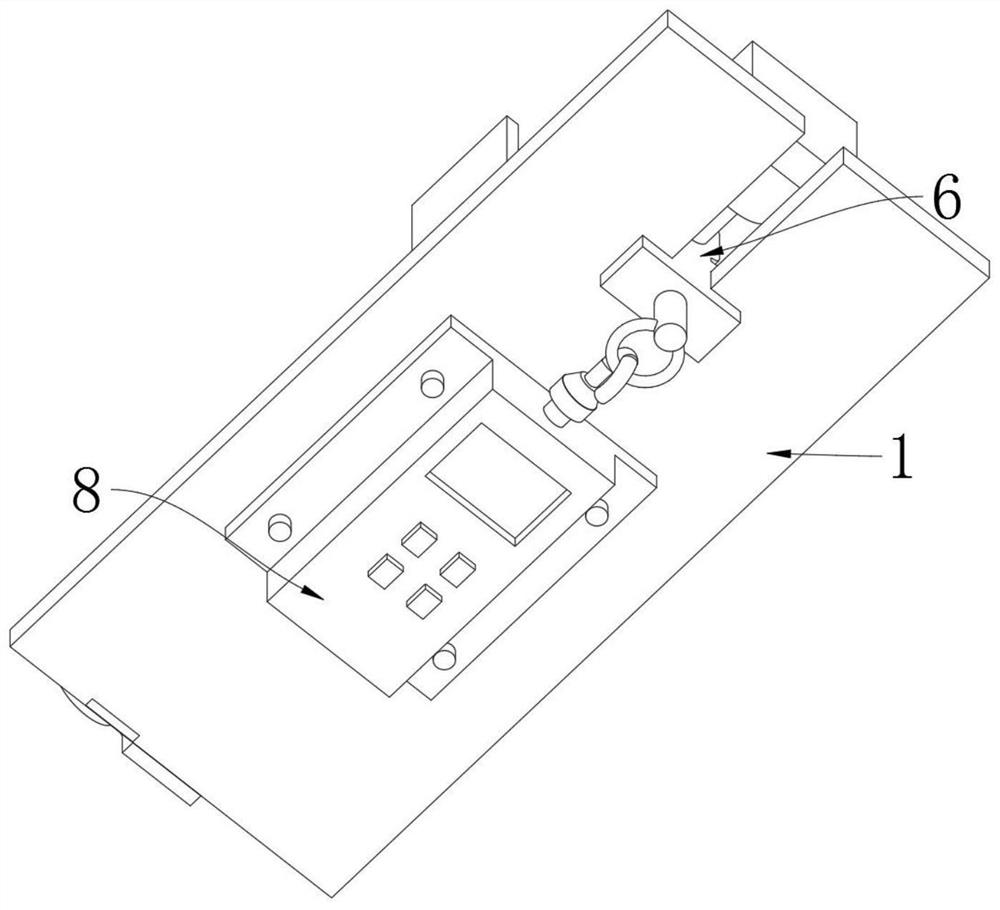

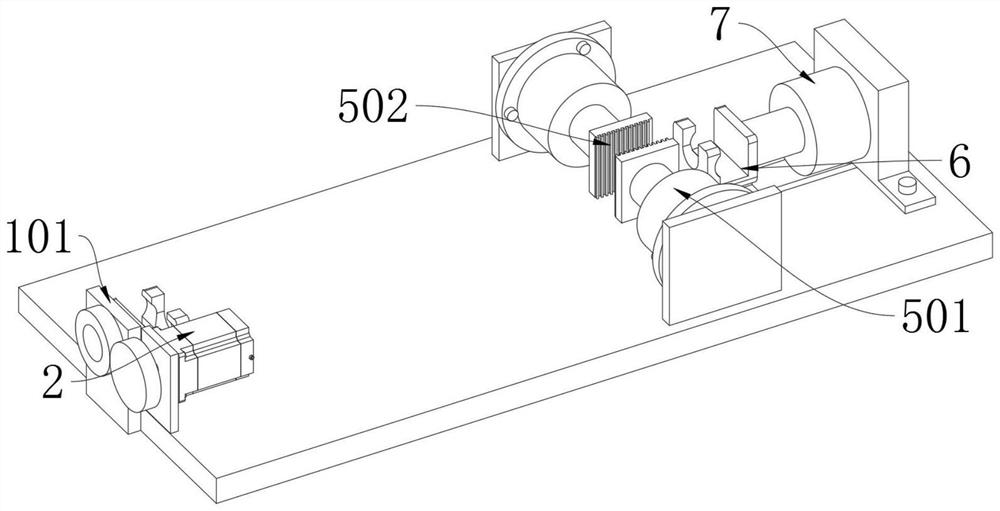

[0027] as attached figure 1 To attach Image 6 Shown:

[0028] The invention provides a test platform for the pull-off force of a flexible shaft guide tube for shifting gears, which includes a base 1; The servo motor 2 is fixedly connected, and a rotatably connected mounting block A3 is installed on the base 1; the flexible shaft 4 includes a steel wire rope 401, and the steel wire rope 401 is clamped on the mounting block A3, and the other end of the steel wire rope 401 is clamped on the mounting block On B6, the outer side of the steel wire rope 401 is sleeved with a flexible shaft 4, and a clamp is provided on the flexible shaft 4; two sets of clamping mechanisms 5 are installed on the base 1, and a digital display push-pull device 8 is installed on the base 1; the installation block B6 Cylinder B7 is installed at the bottom of , and cylinder B7 is fixed on the base 1 by bolts.

[0029] Wherein, the base 1 includes a connection block 101, a rectangular connection block 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com