A method for realizing one-time forming of the welding seam of the chassis suspension shell structure

A shell structure and suspension technology, used in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of irregular appearance of the end position of the welding seam, poor accessibility of the welding gun, insufficient length of the welding seam, etc., and the method is flexible. Reliable, accessible, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

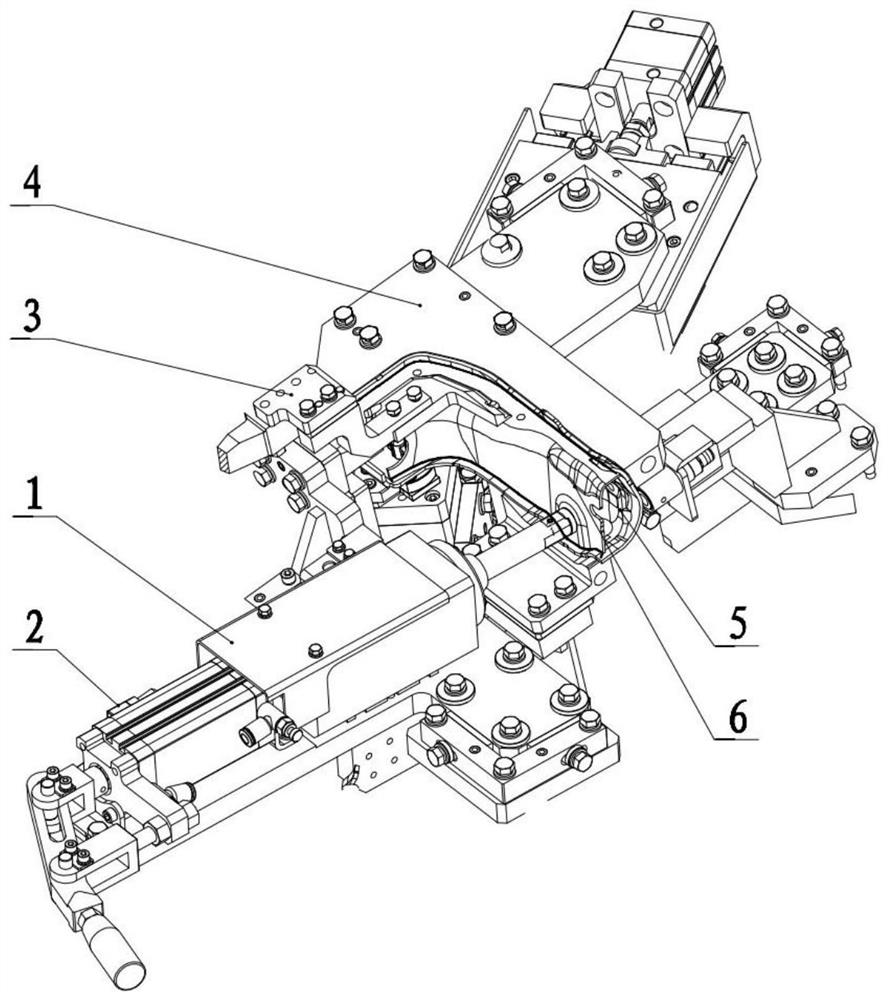

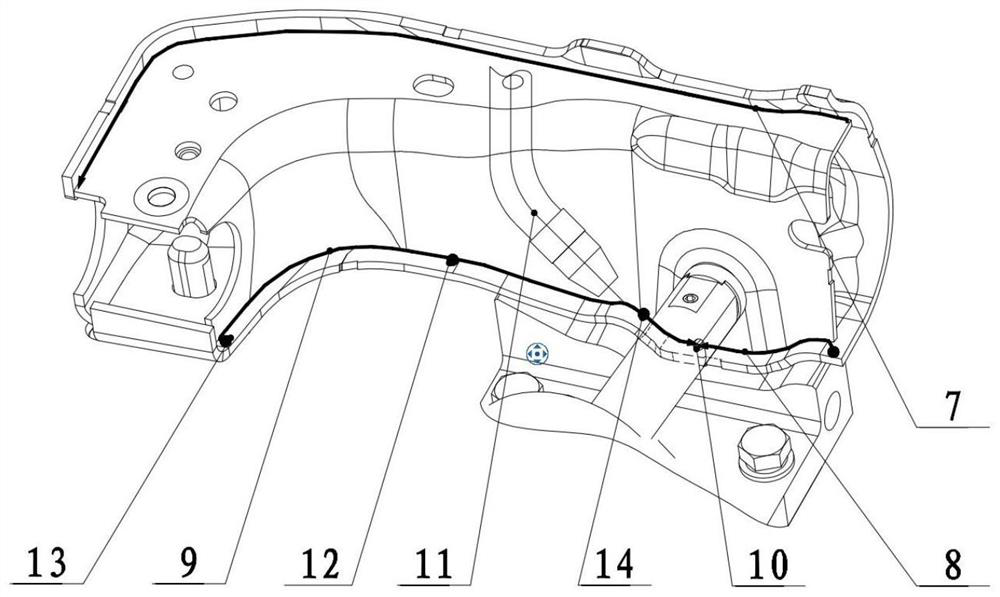

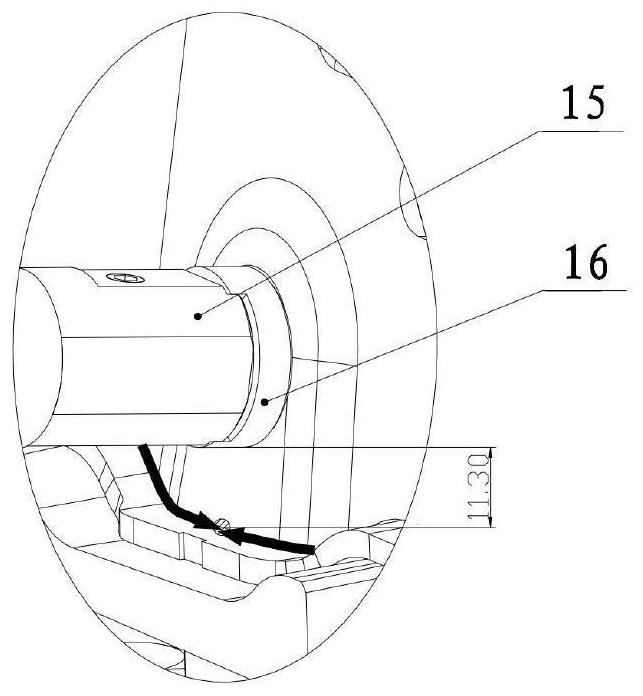

[0033] In the following, the method for realizing the one-time forming of the welding seam of the chassis suspension shell structure according to the present invention will be described in a complete and detailed manner in conjunction with the specific embodiments and the accompanying drawings, in order to understand the process method of the present invention more clearly, but it is not possible to In this way, the protection scope of the present invention is limited.

[0034] see Figure 1-5 , a method for realizing one-time forming of the welding seam of the chassis suspension shell structure, the shell structure includes an outer plate and an inner plate, which are respectively in an "L-shaped" structure and form three welding seams, the method includes the following steps:

[0035] a. The fixture is reset, the outer plate 5 is placed on the fixture, the secondary positioning mechanism 3 is manually pushed to the working position, the inner plate 6 is placed on the fixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com