Antimicrobial composition based on polyphenols and polysaccharides, method for preparing thereof and use of same

An antimicrobial, compositional technology, applied in the fields of chemicals for biological control, botanical equipment and methods, active ingredients of hydroxyl compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

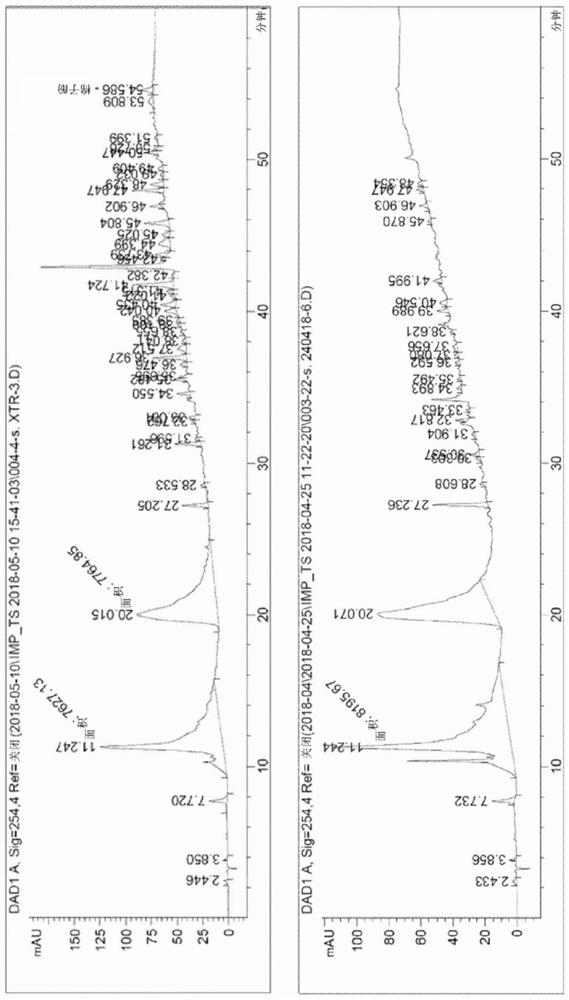

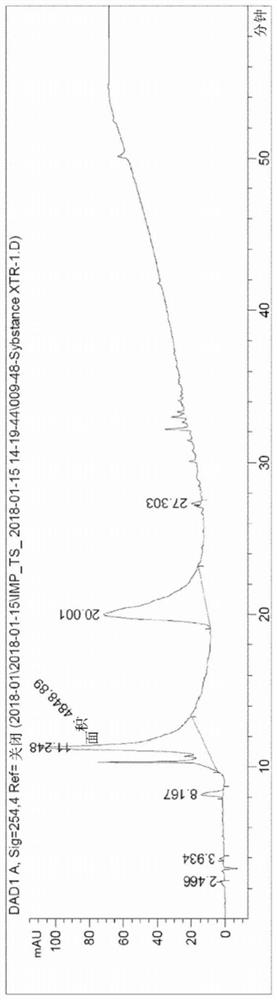

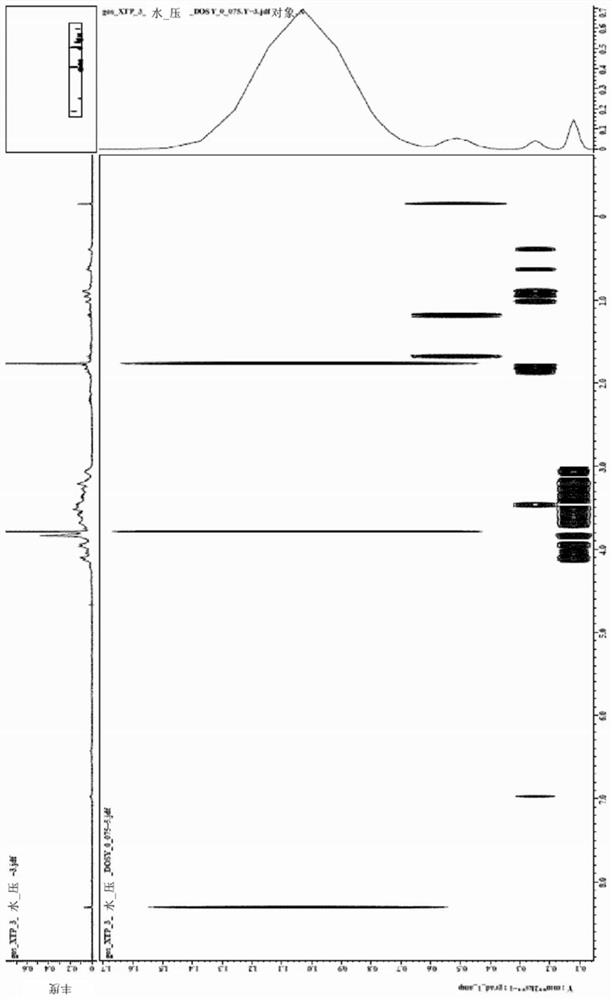

Image

Examples

Embodiment 1

[0133]A 200 ml beaker was filled with 27.6 g of water, and then 60 g of NaOH solution (34.8%) was added thereto. Then, 60 g of dialdehyde carboxymethylcellulose (hereinafter referred to as DACMC) having a carbonyl group content of 0.94 mmol / g was added under stirring while maintaining the temperature not higher than 58°C. The reaction mass was stirred at room temperature for 3 hours, then the stirring was stopped and the reaction mass was aged for 18 hours until the carbonyl content reached 81.4% of the original polymer. The next day, the reaction mass was acidified with 10 g of sodium bicarbonate, stirred for 30 minutes, precipitated from acetone and dried. The yield of the resulting composition was 76.8 g.

Embodiment 2

[0135] A 200 ml beaker was filled with 70 g of NaOH solution (20%). Then, 7 g of DACMC with a carbonyl content of 2.3 mmol / g was added under stirring, and the reaction mass was stirred at 25°C for 60 minutes until the carbonyl content in the polysaccharide reached 26.5% of the original content, and then 23 g of sodium bicarbonate was added into the reaction mass and stirred for 30 minutes. Additionally, the reaction mass was precipitated from acetone and dried in a dry heat oven. The yield of the resulting composition was 39.2 g.

Embodiment 3

[0137] Fill a 200ml beaker with 70g of Na 2 CO 3 solution (20%). Then, 7 g of DACMC with a carbonyl content of 2.3 mmol / g was added under stirring, and the reaction mass was stirred at 25° C. for 180 minutes until the carbonyl content in the polysaccharide reached 62.2% of the original content. Additionally, the reaction mass was precipitated from acetone and dried in a dry heat oven. The yield of the resulting composition was 18.8 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com