Gas turbine engine operable at very low partial load and method of controlling a gas turbine engine

A technology of gas turbine and engine, which is applied in the direction of engine control, gas turbine device, fuel control of turbine/propulsion device, etc., and can solve problems such as fine control incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

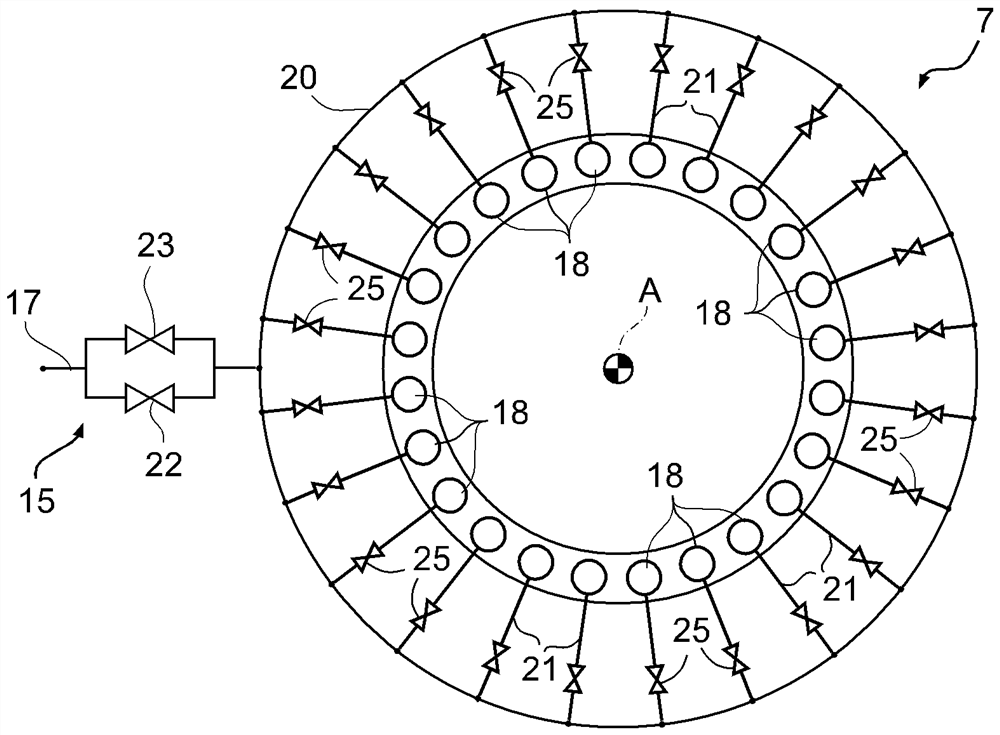

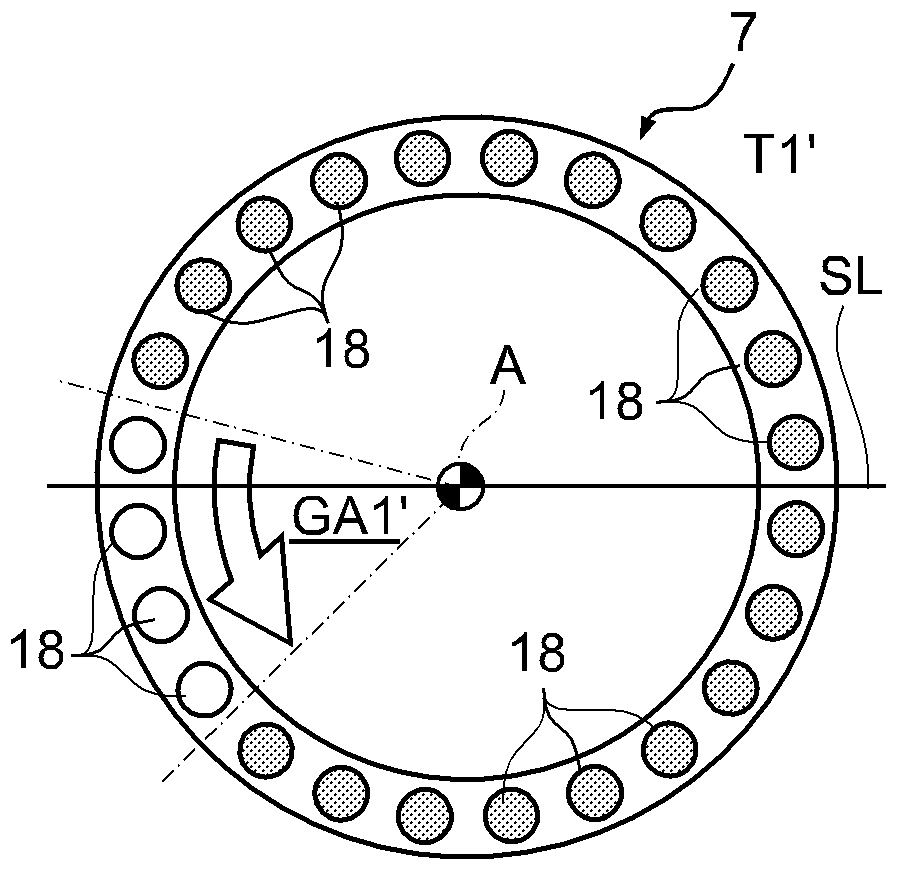

[0026] figure 1 A simplified view of a gas turbine engine generally designated by the numeral 1 is shown. The gas turbine engine 1 comprises a compressor 2 , a first stage combustor 3 , a high pressure turbine 5 , a second stage combustor 7 (also called sequential combustor) and a low pressure turbine 8 .

[0027] The fuel supply system 9 delivers fuel flow to operate the first stage burner 3 and the second stage burner 7 .

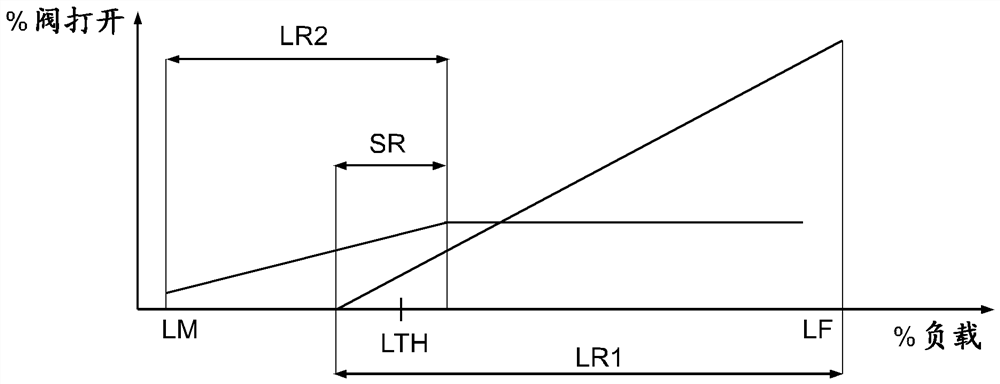

[0028] A controller 10 receives status signals from system sensors 11 and operates the gas turbine through actuators to provide a controlled power output. The actuators comprise an orientable inlet guide vane 12 of the compressor 2 and a first stage fuel valve system 13 and a second stage fuel valve system 15 of the fuel supply system 9 .

[0029] The compressed air flow supplied by the compressor 2 is increased by a first fuel flow M1 and the air / fuel mixture thus obtained is combusted in a first stage burner 3 . The exhaust gas of the first stage com...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap