PCB board welding and fixing tooling

A technology of PCB board and fixed tooling, applied in welding equipment, manufacturing tools, auxiliary devices, etc., can solve the problem of PCB board welding inconvenience, and achieve the effect of reducing omission, reducing the possibility of loosening, and improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

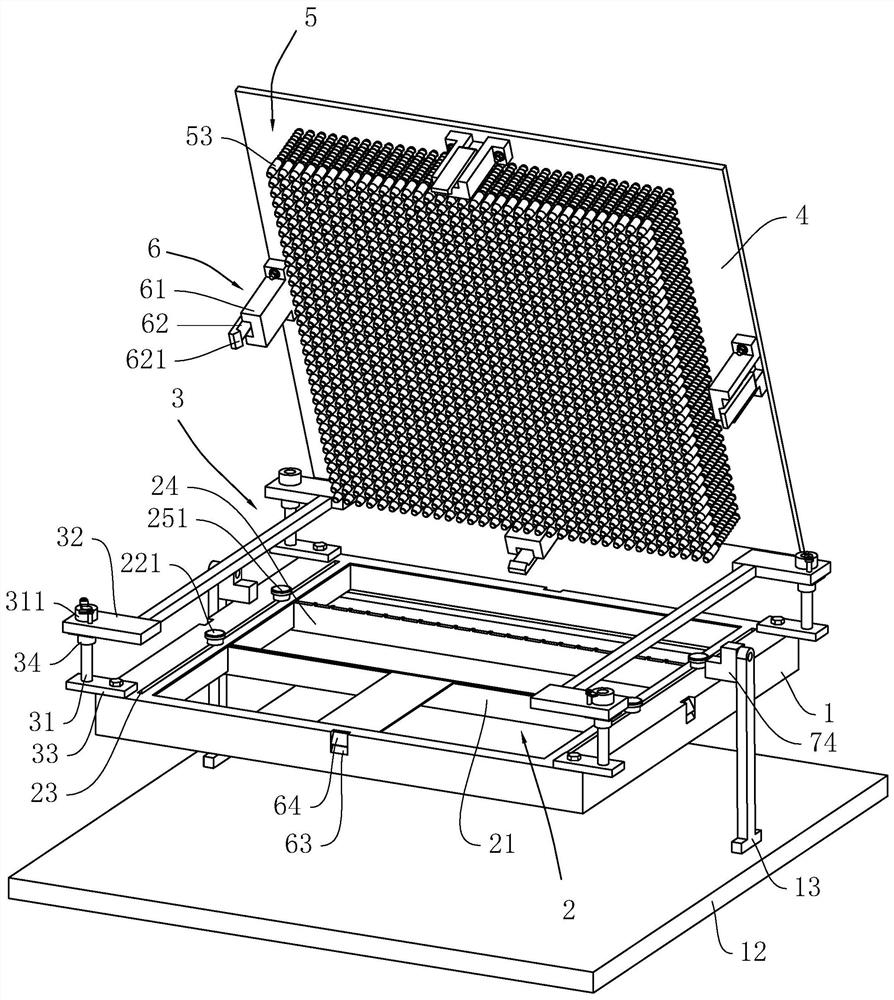

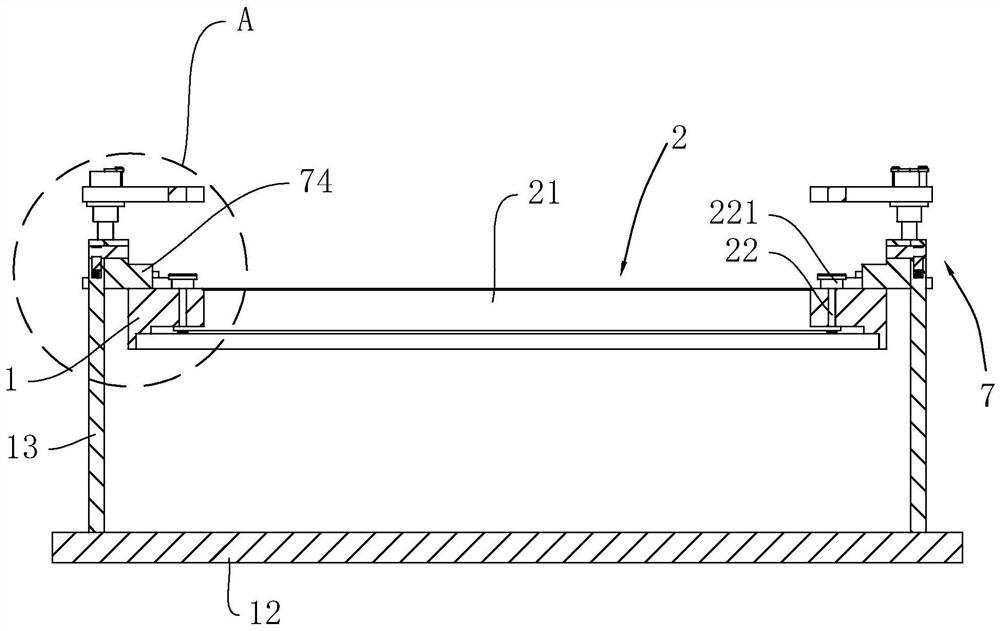

[0039] The embodiment of the present application discloses a PCB board welding and fixing tool. As shown in Figure 1 and Figure 2, the PCB board is welded to fix the tooling package

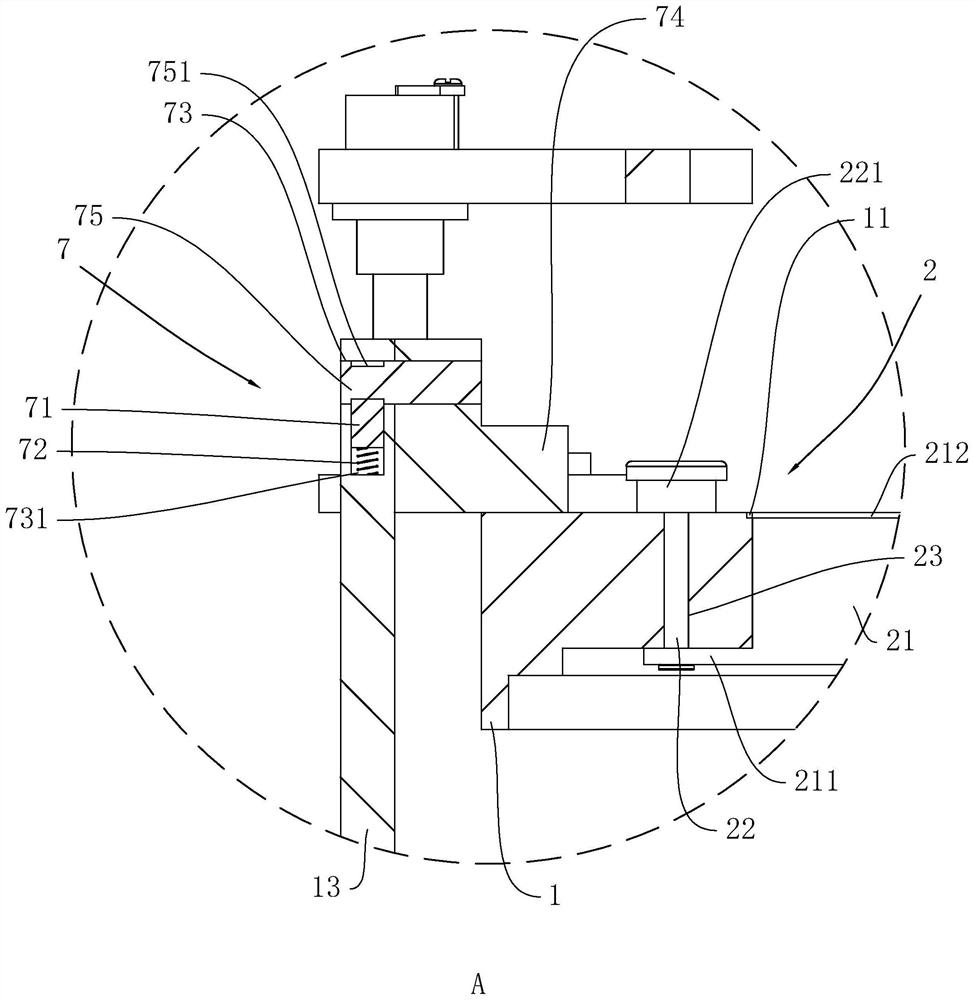

[0046] As shown in Figure 4, the lifting cage 3 includes two sets of sliding bars 31 vertically arranged on the bottom frame 1, and the two sets of sliding bars 31 are located at

[0047] As shown in Figure 4, the top of each slide bar 31 is threadedly connected with a positioning block 311, and the bottom frame 1 is located below the positioning block 311, wherein

[0049] In the actual design, the first dial block 321, the second dial block 322 and the positioning block 311 are all made of rubber or plastic material,

[0050] As shown in Figure 6, the elastic telescopic column 5 includes a guide column 51, an end cap 52 and a pressure cap 53, and the panel 4 is vertically provided with a number of edge

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com