Polishing solution recovery device and method using double vacuum pump bodies

A technology for recycling device and polishing liquid, applied in the field of polishing liquid recycling device with double vacuum pump body, can solve the problems of insufficient vacuum strength, affecting the effect of magnetorheological processing elements, etc., and achieve the effect of efficient recycling and improving stable working state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following description provides a number of different embodiments, or examples to implement different features of the present invention. The elements and arrangements described in the following specific examples are intended to be intended to be illustrative, and is not intended to limit the invention.

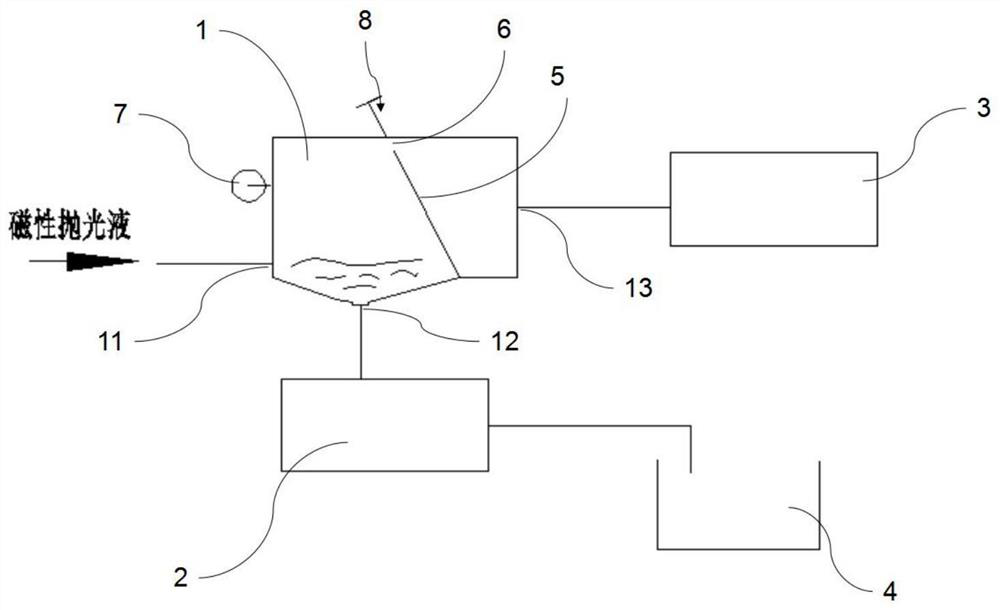

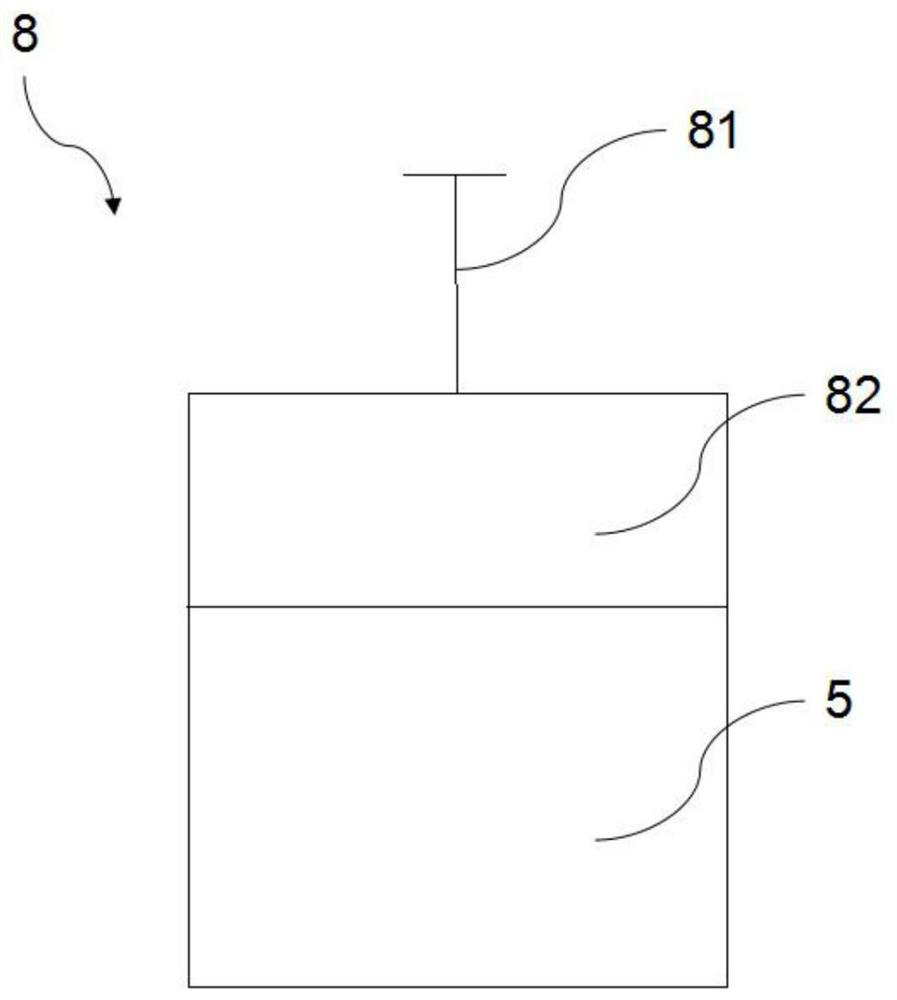

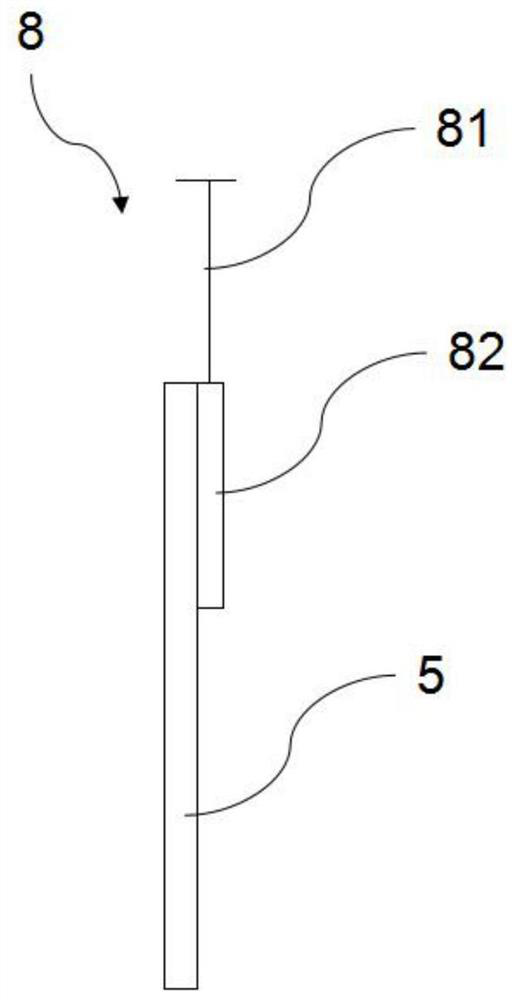

[0032] See figure 1 , The example of the present invention discloses a double vacuum pump polishing liquid recovery device including a vacuum cavity 1, a first vacuum pump body 2, a second vacuum pump body 3, and a polishing liquid storage device 4;

[0033] The vacuum cavity includes an input interface 11, a first vacuum interface 12, a second vacuum interface 13;

[0034] The polishing liquid enters the vacuum cavity 1 through the input interface 11, and the first vacuum pump body 2 communicates with the vacuum cavity 1 through the first vacuum interface 12, the second vacuum pump body 3 through which The second vacuum interface 13 communicates with the vacuum cavity 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com