A Direct Resistance Heating Device for Additive Manufacturing Wire Feeding Process

A resistance heating and additive manufacturing technology, used in additive processing, manufacturing tools, resistance welding equipment, etc., can solve the problems of unhealthy operators, limited application scope, low heating efficiency, etc., to achieve reliable heating effect, The effect of improving heating efficiency and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

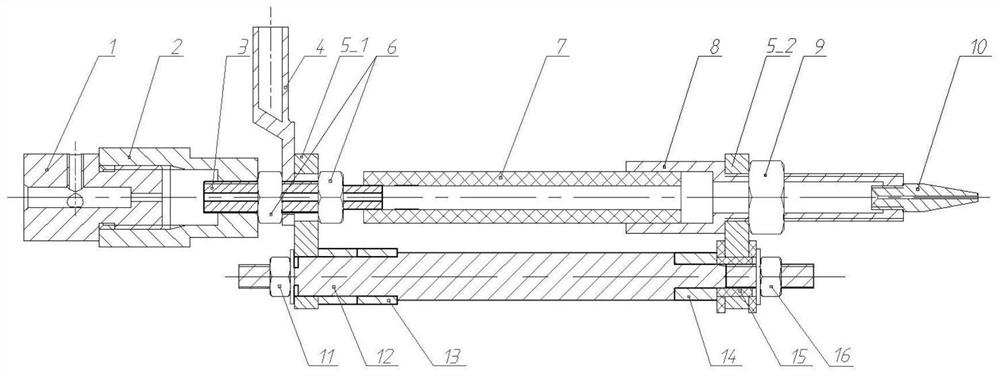

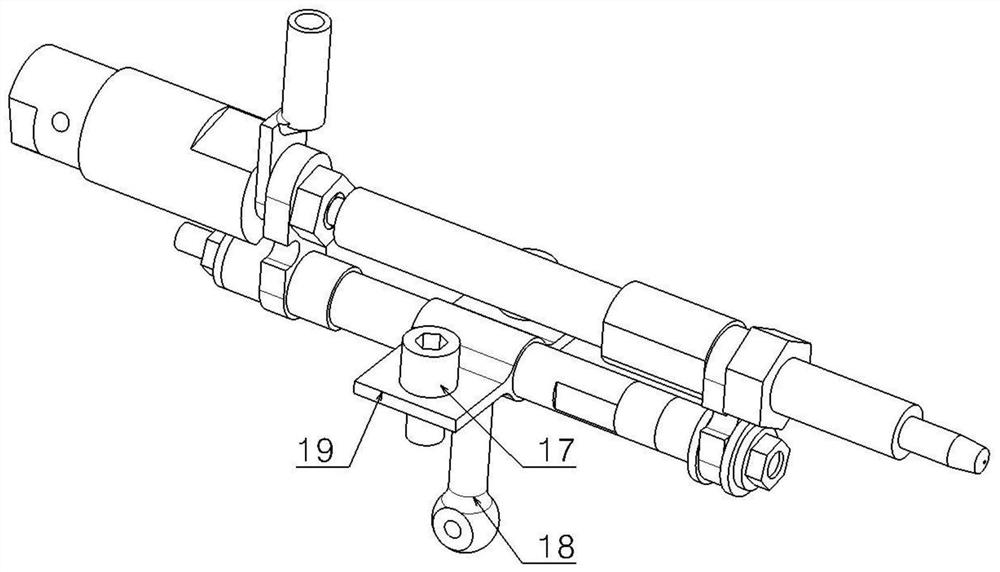

[0048] This embodiment describes the specific implementation of the direct resistance heating device for the wire feeding process of additive manufacturing proposed by the present invention. figure 1 and figure 2 shown.

[0049] The direct resistance heating device for the wire feeding process of the additive manufacturing includes: an adapter fixing component, a direct resistance heating wire component, a wire feeding hose connector 1, an adapter 2 and several copper nuts.

[0050] Among them, the transfer fixing assembly includes the left end transfer chuck 5_1, the right end transfer chuck 5_2, the main shaft 12, the first adjusting ring 13, the second adjusting ring 14, the PTFE component 15, the bolt and nut fastening component 17, the fixing pipe The bracket 19 and the joint bolt 18; the main shaft 12 is connected to the resistance heating wire assembly through the left and right end adapter chucks 5_1, 5_2, and the left and right ends of the adapter chuck 5_1, 5_2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com