Drill

A drill and drill tip technology, applied in the field of drills, can solve problems such as increasing the feed rate, and achieve the effect of consistent outreach

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

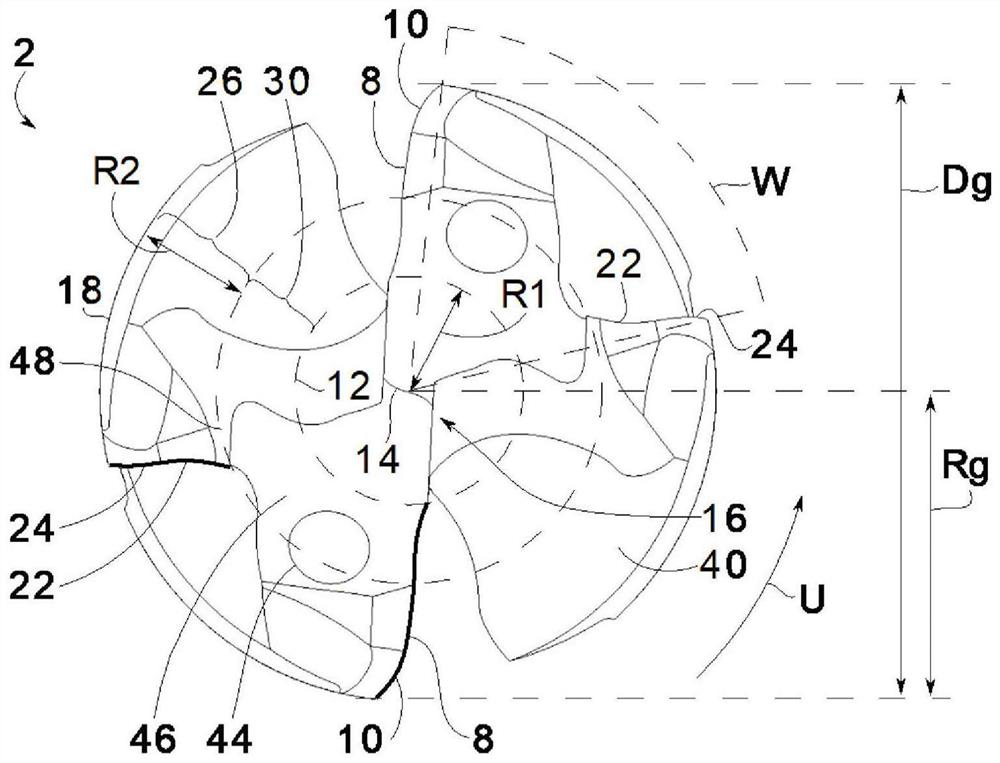

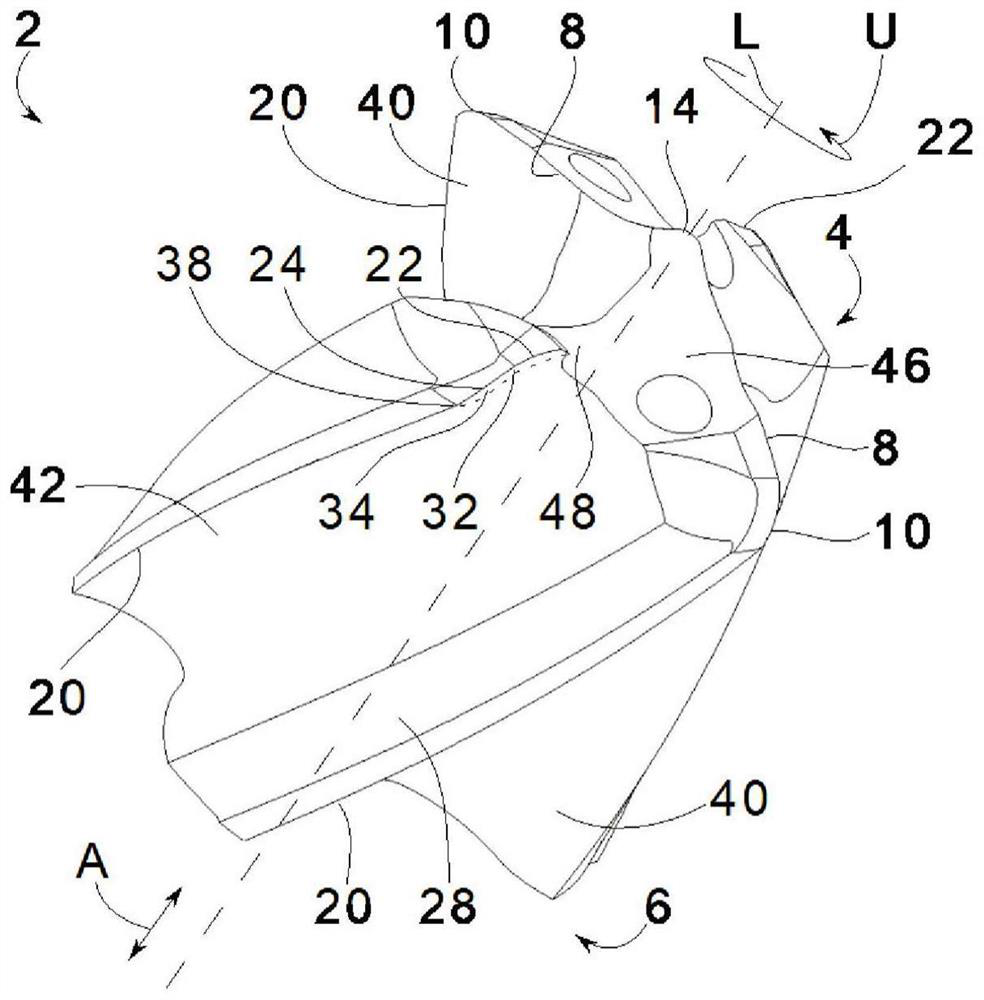

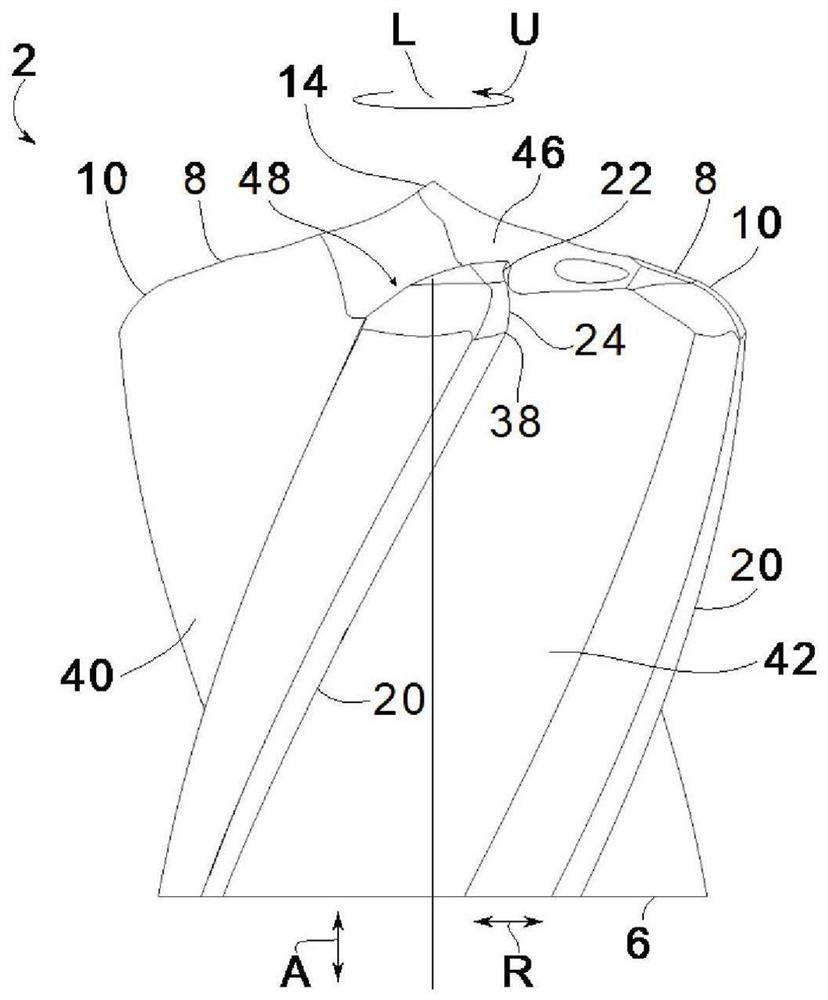

[0039] Figure 1-4 A design example of a drill 2 for machining a workpiece not depicted by drilling is shown. In general, the drill 2 is a rotary tool extending along a longitudinal axis L around which the drill 2 rotates in a direction of rotation U during operation. figure 1 A front view of the drill 2 is shown, figure 2 shows a perspective view, and image 3 and 4 shows the corresponding side view, whereby image 3 The view is from Figure 4 The view in is rotated by 90° in the direction of rotation U. The drill 2 comprises a drill point 4 formed on the front side of the drill 2 and thus facing the workpiece during operation. In the design example shown, the drill tip 4 is formed in one piece with the base body 6 of the drill 2 , ie monolithically. In an alternative not depicted, the drill tip 4 is configured as a cutting insert of the base body 6 of the drill 2 .

[0040] The drill tip 4 comprises at least one main cutting edge 8 with a cutting corner 10 extending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com